The Fi Europe will be held from November 28th to 30th, 2023 at the Frankfurt International Convention and Exhibition Center in Germany. Every two years, Fi Europe was first launched in 1986 and has since grown into a trade summit and industry benchmark for the global food ingredient industry. According to statistics, over 500000 people have participated in this grand event and created billions of euros in business. Fi Europe is held every two years in major European cities, bringing together world leading food and beverage suppliers, research and development, production, and marketing experts, and showcasing the most diverse range of innovative ingredients and services.

Fi Europe is mainly composed of Ni and FT, with natural ingredients (Ni) mainly showcasing food related products such as natural organic supplements, health products, functional foods, and beverages. FT is mainly a one-stop service that provides processing, packaging, equipment and other solutions for the food industry.

In recent years, Chinese food ingredients have gradually gained popularity in the international market due to their rich variety, good quality, and affordable prices. Fi Europe has become one of the undisputed world’s leading food ingredient exhibitions, with huge demand growth. This exhibition not only expands overseas markets, but also enhances international market competitiveness.

The Fi Europe, which takes turns hosting major cities in Europe, brings together world leading food and beverage suppliers, showcasing the most diverse and innovative materials and services.

In the food and beverage industry, it is hailed as one of the most important exhibitions. 96% of exhibitors believe that Fi Europe is “very important” to their business.

As one of China’s best suppliers of mortar additives, SIDLEY has permanently attached great importance to the relevant coating exhibitions while we will show customers our rich samples and the most advanced technology this time. SIDLEY focuses on the application development and product promotion of chemicals such as mortar and coating additives. In addition, SIDLEY will bring customers more comprehensive products and customization solutions. This time SIDLEY will bring hydroxypropyl methylcellulose; hydroxyethyl cellulose; carboxymethyl cellulose; calcium formate; re-dispersible polymer powder; starch ether, and other products. SIDLEY looks forward to your visit at the Stand [4.1L60].

HPMC is an essential additive in dry-mixed mortar and has extensive uses in the building materials industry. It is vital in tile adhesive, ready-mixed mortar, putty, and gypsum. We provide various functional cellulose ether by adjusting the production process to help customers improve their performance and make them more competitive.

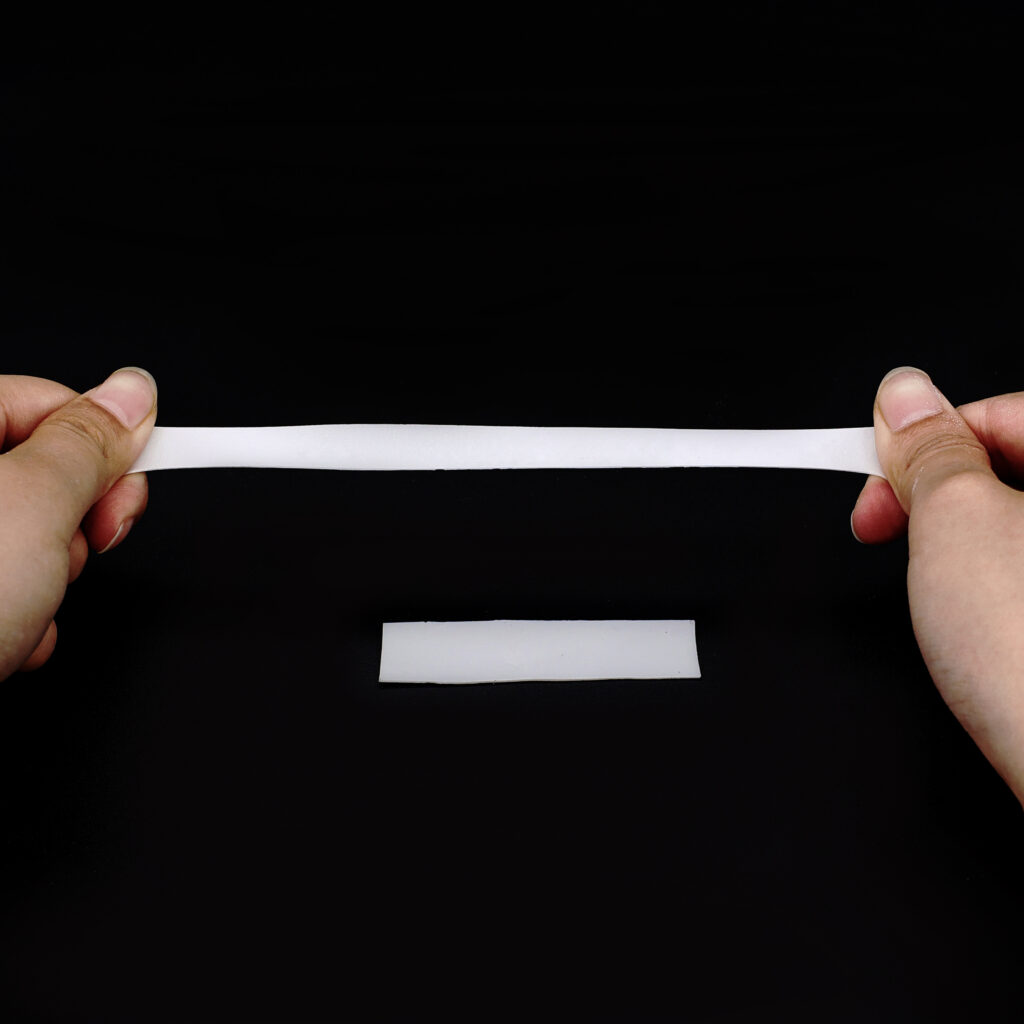

Sodium carboxymethyl cellulose ( CMC ) is an anionic cellulose ether product made from natural cotton fiber as the primary raw material through alkalization, etherification, purification, drying, crushing, or granulation. The appearance of CMC is white powder or granules, and its water-soluble colloid has the functions of thickening, stabilizing, emulsifying, suspending, and film-forming. They are widely used in food, toothpaste, paper, ceramics, printing and dyeing, oil drilling, and other industries.

RDP is a significant mortar additive produced by Sidley which can improve mortar strength and weather resistance with excellent adhesion to various substrates. It is an indispensable additive in dry-mixed mortar. The RDP is made of Celanese emulsion, which forms a free-flowing white powder after spray drying. The powder can form a stable dispersion after being stirred with water, and its properties are similar to those of the original emulsion. That is, after the water evaporates, a film is formed. This film has high toughness and excellent adhesion to various substrates. They are widely used in external wall insulation, tile adhesive, putty, and other products. We recommend RDP-8044, 8013, 6013, and other products to customers that are suitable for mortar systems.

Polycarboxylate superplasticizer has ultra-high water reducing rate, excellent concrete slurry state, linear slump loss, suitable for customer on-site mixing and prefabricated parts factories. Recommended model: PCE154L

Polyester fiber has the advantages of high strength, corrosion resistance, high-temperature resistance, strong chemical stability, and binding solid force with asphalt. When added to asphalt concrete, it forms many three-dimensional random distributions of fiber monofilaments after stirring, which can effectively improve the mechanical properties of asphalt mixture and prevent the cracking of asphalt concrete.

More product information can be found at booth4.1L60! Welcome everyone to join us! We will see you there!