Exhibition Name: ABRAFATI 2023

Exhibition Time: November 2023, 21-23, 2023

Organizers: Brazilian Coatings Association (ABRAFATI)

Organizer: Brazilian Coatings Association

Venue: Sao Paulo, Brazil

Booth No.: A97

ABRAFATI 2023 will be held on November 21-23, 2023 in Sao Paulo, Brazil. The biennial exhibition, organized by the Brazilian Coatings Association (ABRAFATI), has been held for sixteen consecutive sessions and will celebrate its seventeenth event in 2023. At the 2023 edition of Brazil Coatings, there were 290 exhibitors from more than 30 countries and regions around the world (a 33% increase from the previous edition), with an exhibition area of 28,000 square meters, attracting more than 16,000 visitors to the show. The exhibition is the most large-scale and influential coatings professional exhibition in South America, its exhibition area and the number of visitors not only in South America, but also in the world’s coatings industry in the scope of the top. Its exhibitors include Dow Chemical, BASF, Bayer, DuPont, Evonik, Eastman, Air Products, Clariant, Huntsman, Merck, LANXESS, Rhodia, Rohm and Haas, Biochem and many other multinational chemical giants, with an extremely comprehensive industry coverage.

Brazil is a large country in Latin America, with its land area, population and GDP ranking first in Latin America, and is the world’s sixth largest economy, as well as one of the world’s largest paint investment markets, occupying nearly half of the Latin American market. In terms of coatings, Brazil has 300 coatings manufacturers, 16,000 employees and is growing at a rate of 4.4% per year; and, coatings consumption accounts for 25% of Brazil’s total value, with per capita consumption reaching 20 liters per person. The growth of the Brazilian paint industry is mainly reflected in the automotive paints and decorative coatings. Our paint products have gained high popularity and market share in the international market with reliable quality and low price. And the national economy of South America has recovered a lot in recent years and is now in the upturn of rapid growth, so it is the best time for our coating products to enter the South American market. At the same time, Brazil is the largest country in South America, and its total economy is the first in South America, which has a strong radiation ability to the neighboring countries, so Brazil Coatings Expo will attract a large number of businessmen from South America to negotiate. Participating in this exhibition is very favorable for expanding product publicity and exploring the markets of South American countries.

As a new material enterprise, Shengde Chemical has been active in the stage of the International Coatings Exhibition. This time, Shengde Chemical brought a variety of innovative solutions for dry mortar additives to the exhibition hall, showing the green and innovative manufacturing technology to the Southeast Asian coatings market in an all-round way to help customers customize their products and enhance the value of their products and services!

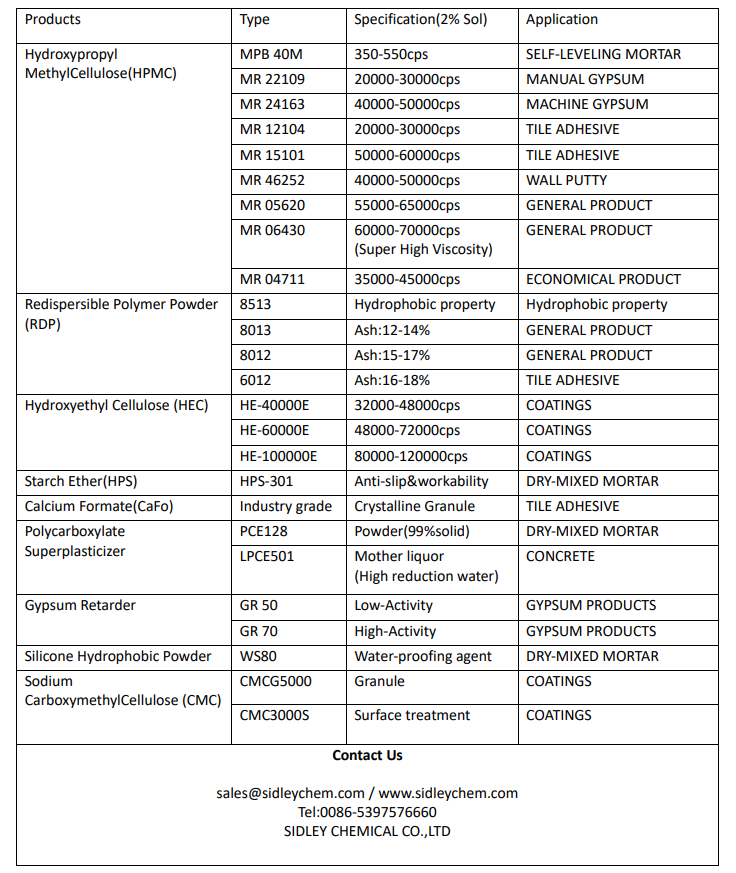

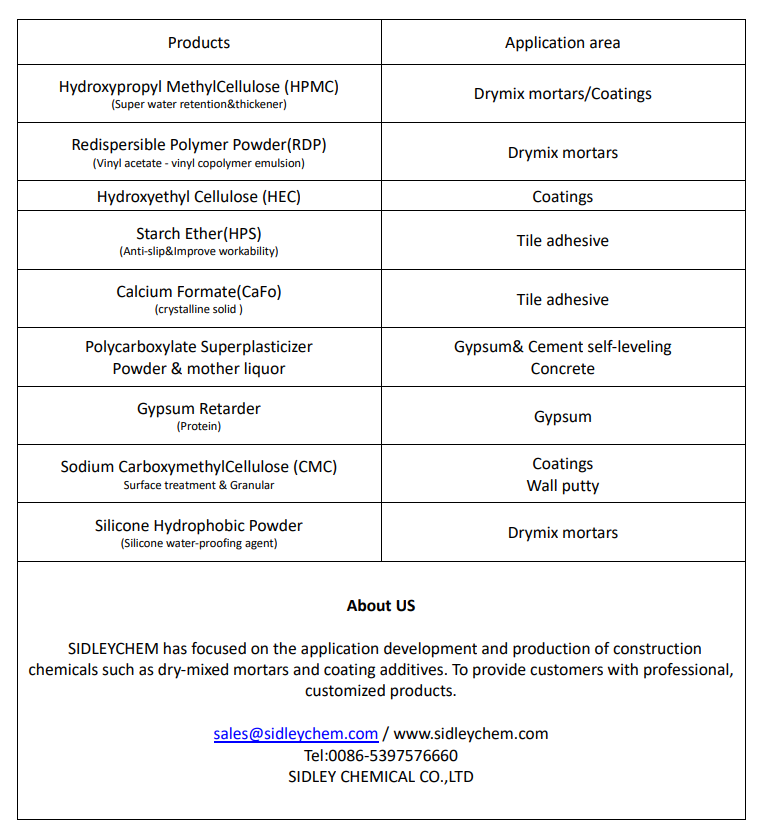

Centec will bring more comprehensive product customization solutions to customers. In this exhibition, Shengde will bring Hydroxypropyl Methyl Cellulose, Hydroxyethyl Cellulose, Carboxymethyl Cellulose, Calcium Formate, Dispersible Latex Powder, Starch Ether and other products. We sincerely look forward to seeing you at our booth [A97].

We will bring the following products to the exhibition:

HPMC is an essential additive in dry-mixed mortar and has extensive uses in the building materials industry. It is vital in tile adhesive, ready-mixed mortar, putty, and gypsum. We provide various functional cellulose ether by adjusting the production process to help customers improve their performance and make them more competitive.

Sodium carboxymethyl cellulose ( CMC ) is an anionic cellulose ether product made from natural cotton fiber as the primary raw material through alkalization, etherification, purification, drying, crushing, or granulation. The appearance of CMC is white powder or granules, and its water-soluble colloid has the functions of thickening, stabilizing, emulsifying, suspending, and film-forming. They are widely used in food, toothpaste, paper, ceramics, printing and dyeing, oil drilling, and other industries.

RDP is a significant mortar additive produced by Sidley which can improve mortar strength and weather resistance with excellent adhesion to various substrates. It is an indispensable additive in dry-mixed mortar. The RDP is made of Celanese emulsion, which forms a free-flowing white powder after spray drying. The powder can form a stable dispersion after being stirred with water, and its properties are similar to those of the original emulsion. That is, after the water evaporates, a film is formed. This film has high toughness and excellent adhesion to various substrates. They are widely used in external wall insulation, tile adhesive, putty, and other products. We recommend RDP-8044, 8013, 6013, and other products to customers that are suitable for mortar systems.

Polycarboxylate superplasticizer has ultra-high water reducing rate, excellent concrete slurry state, linear slump loss, suitable for customer on-site mixing and prefabricated parts factories. Recommended model: PCE154L

Polyester fiber has the advantages of high strength, corrosion resistance, high-temperature resistance, strong chemical stability, and binding solid force with asphalt. When added to asphalt concrete, it forms many three-dimensional random distributions of fiber monofilaments after stirring, which can effectively improve the mechanical properties of asphalt mixture and prevent the cracking of asphalt concrete.

In the future, Shengde Chemical will continue to strive for greater breakthroughs in the field of dry mortar additives by strengthening the upstream and downstream synergistic innovation of the industrial chain. We will proactively grasp the development opportunities of economic and trade cooperation and innovation, and continue to work hard to lead the global dry mortar industry towards the road of high-quality and sustainable development, so that the “Made in China” dry mortar additives can reach all over the world.

The following are the samples that will be presented to this exhibition. You are welcome to visit the booth anytime for further information.