In recent years gypsum has been used more and more widely in the construction engineering, and the use of gypsum based dry mortar has become the main product of dry mortar. For example, as the interior wall plastering material, plastering gypsum has the functions of light weight, anti-inflammatory, sound insulation, heat preservation, sound absorption, etc. It is the preferred material to replace the traditional mortar plastering. Gypsum building materials such as gypsum board, gypsum block, gypsum joint filler agent, gypsum strip board, self leveling gypsum and gypsum board adhesive have been widely used in the construction industry at home and abroad, as shown in picture 4.5-1.

The raw material of gypsum in China is mainly hemi-hydrate gypsum, containing a small amount of over-burned gypsum, which is a kind of pneumatic cementitious material. The setting time of hemi-hydrate gypsum is usually 3~10 min after encountering water, which brings a lot of inconvenience to the construction. At the same time, due to the fast setting, it has a negative impact on the bond strength and the final product quality. Therefore, it is very important to effectively control and extend the setting time of gypsum products. For the construction requirements of gypsum based products, the opening time shall be at least 2-3h to ensure the normal construction. In the field construction, the gypsum products close to the solidification can not be reused with water. Gypsum retarder has become one of the indispensable additives in all gypsum based products.

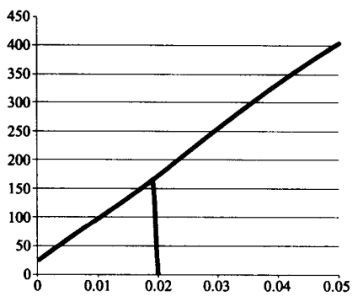

Picture 4.5-1 Initial setting time (min) and dosage (%)

The commonly used gypsum retarders are mainly modified protein, citrate, tartrate and potassium hydrogen phosphate. Although these retarders can effectively extend the opening time of gypsum products, they also affect the later strength of gypsum products.

At present, the domestic gypsum retarder can effectively solve the problem of gypsum setting too fast. The imported products are mainly gypsum retarder series produced by TRICOSAL company of Germany. The main component is calcium salt of polymethyleneaminic acid, pH value 12, chlorine content <0.1%, good solubility in water. The operation time of gypsum products can be adjusted according to the amount of addition, without negative impact on the strength and cohesiveness of the final products. With the addition of gypsum commercial retarder, the hydration heat of gypsum in the hydration reaction can be greatly reduced, so as to avoid cracking and bond strength reduction caused by rapid hydration reaction.