Characteristics of nature cellulose fiber

(1)Fiber reinforcement and thickening effect

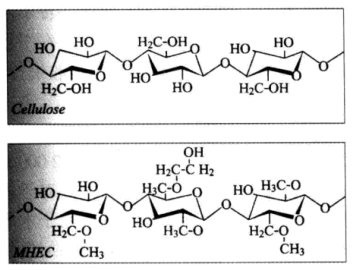

The nature cellulose fiber has a three-dimensional network structure with obvious cross-linking effect, as shown in picture 4.4-2. This structure can effectively adhere to the liquid structure, such as water, latex paint, asphalt and other liquids with different consistency. Its thickening depends on the length of the fiber. The longer the fiber is , the greater the thickening effect of the base. Because of its special structure, it can completely replace asbestos products.

Picture 4.4-2 Molecular structure of nature cellulose fiber

(2) Improve constructability.

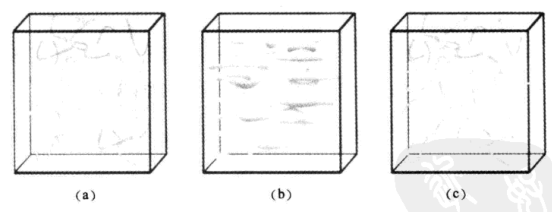

When the shear force acts on the three-dimensional network structure of the cellulose fiber, such as wiping, stirring, pumping, etc, the adsorbed liquid in the structure will be released into the system and the fiber structure changes and arranges along the direction of movement, resulting in the decrease of viscosity and the improvement of workability. When the shear force stops, the fiber structure returns the original three-dimensional network structure, absorbs the liquid and returns the original viscosity state.

Picture 4.4-3 Cellulose Fiber structural change

- Three dimensional network structure of cellulose fiber

- Under the action of shear, the fiber structure is arranged in the direction of movement and the viscosity decreases.

- Once the shear force disappears, the three-dimensional reticulated structure will be restored immediately

(3) Good liquid absorption function

Cellulose fiber can absorb and transport liquid through its capillary action. Once the three-dimensional network structure is in a static state, such as after the cement mortar is solidified, the cellulose fiber can be tightly adhered to the cement mortar, as a kind of sealing layer, which can prevent the moisture and rain from penetrating, as show in picture 4.4-4

Picture 4.4-4 Cellulose fiber water delivery structure

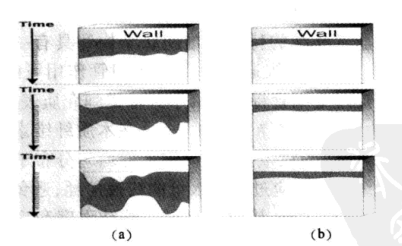

(4) Excellent sagging resistance

Due to the reinforcement and thickening of cellulose fiber, when a proper amount of fiber is added, the ticker plastering can be completed at one time without falling, which is very important in construction. For the dry powder paint and emulsion paint, there will be no sagging phenomenon. Picture 4.4-5 shows the flow resistance of cellulose fiber.

Picture 4.4-5 Flow chart of vertical faccade construction

- Uncoated with cellulose fiber

- Coated with cellulose fiber

(5) Crack resistance

The three-dimensional network structure of cellulose fiber can effectively absorb and weaken the mechanical energy produced in curing and drying process.

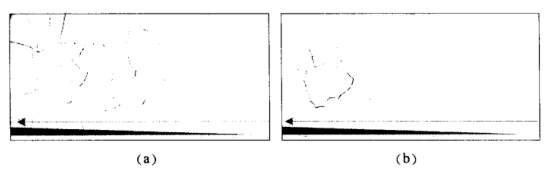

(6) Reduced contractility

Due to the good dimensional stability of cellulose fiber, it can greatly reduce the shrinkage and improve the crack resistance after drying. Picture 4.4-6 shows the effect of adding and not adding fibers on the wall crack resistance.

Picture 4.4-6 Impact on wall

- Uncoated with fiber (b) Coated with 0.5% fiber

(7)Extended opening time

In the construction process, the hydration reaction of cement mortar will release a lot of heat and absorb water. If the opening time is very short, the drying time will be fast and lead to the rapid volume shrinkage and cracking of cement mortar.

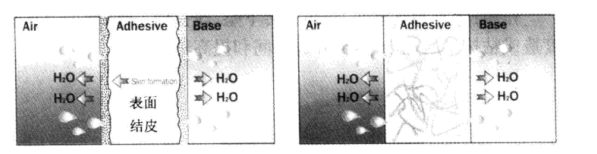

Therefore, the special three-dimensional network structure and certain water retention property of cellulose fiber are particularly important. Its fiber can absorb liquid through its own capillary action. When curing, the internal moisture is transmitted to the surface of the medium through the capillary to reduce the occurrence of skinning, as shown in Picture 4.4-7 and 4.4-8. Under the dual action of cellulose and water retaining agent (such as methyl cellulose), the water can be evenly distributed in cement mortar, which can greatly slow down the rapid consumption of water in the hydration reaction process, avoid the strength drop and cracking caused by too fast water loss, so as to significantly improve the bonding strength and surface strength of the material. Cellulose fiber can not be used as water retaining agent alone, thickener, and it needs to be used together with methyl cellulose ether to achieve the best effect of water retaining, thickening, strengthening and crack resistance.

- No fiber added

- Add fiber