Polyvinyl Alcohol powder as a kind of water-soluble film-forming bonding material, it has also been widely used in some dry mortar products in recent years, especially the appearance of powder polyvinyl alcohol products, which provides a cheaper bonding material for powder and paste putty. Although polyvinyl alcohol powder can be added to dry powder mortar products like redispersible polymer powder to increase its bonding strength, its comprehensive performance is far from the protective colloid function of redispersible polymer powder, but it really realizes low-temperature flexible bonding, reflecting better impermeability, alkali resistance, abrasion resistance, impact resistance, water retention, it is still made of vinyl acetate ethylene and vinyl acetate -Ethylene TERT carbonate copolymer to complete. Therefore, the prices of the two are quite different, but for the production of some low-cost dry mortar products, polyvinyl alcohol powder can be used, but the addition amount should be increased appropriately. Due to the strong hydrophilicity of PVA, its water resistance is poor.

The alcoholysis degree of polyvinyl alcohol powder is about 88%, which can be well dissolved in water, and the water-soluble viscosity is also large. Therefore, polyvinyl alcohol powder can be easily prepared into 801802 glue, which can be used as paste internal wall putty and white cement, talcum powder and as adhesive of external wall putty and interface agent.

Main applications

The application of polyvinyl alcohol in the construction industry mainly includes the following aspects:

(1) Emulsifier in water-soluble coating;

(2) emulsifying agent in vinyl acetate emulsion.

(3) Make protective colloid in redispersible latex powder;

(4) As the main raw material of 802 glue production;

(5) In dry mortar products, adding polyvinyl alcohol powder can improve the adhesion and flexibility of cement mortar, and prevent the plaster from cracking and falling off.

Basic characteristics of polyvinyl alcohol

1.Viscosity: Its viscosity changes with variety, concentration and temperature. When the concentration increased, the viscosity value increased sharply, and the temperature increased, the viscosity decreased obviously.

2.Cohesiveness:PVA has strong binding force for hydrophilic porous surface materials, such as paper, textile, wood, concrete, mortar and smooth non absorbent surface.

3.Film forming ability: It can form better flexible film, and the mechanical strength of PVA film can be adjusted by plasticizer.

4.Gas impermeability: after PVA film forming, it has high impermeability for many gases, especially for oxygen, carbon dioxide, hydrogen, helium, hydrogen sulfide, etc. But for chlorine and water vapor, the permeability is high, and the gas passing rate for polyvinyl alcohol is high.

5.Chemical resistance: It has high corrosion resistance to sodium hydroxide, acetic acid, most inorganic acids, sodium nitrate, aluminum chloride, calcium chloride,calcium carbonate, sodium sulfate and potassium sulfate.

6.Water solubility: the solubility of polyvinyl alcohol is closely related to the degree of alcoholysis of the product. The product with 87%-89% alcoholysis degree has the best water solubility. For example, PVA 24-88 has 88% alcoholysis degree. It can be well dissolved in cold water or hot water. Of course, in actual production, the use of hot water can speed up the dissolution. For products with alcoholysis degree of 89%-90% in order to dissolve completely, they need to be heated to 60-70℃;for products with alcoholysis degree of 90%, they only need to dissolve in hot water of 95℃;.

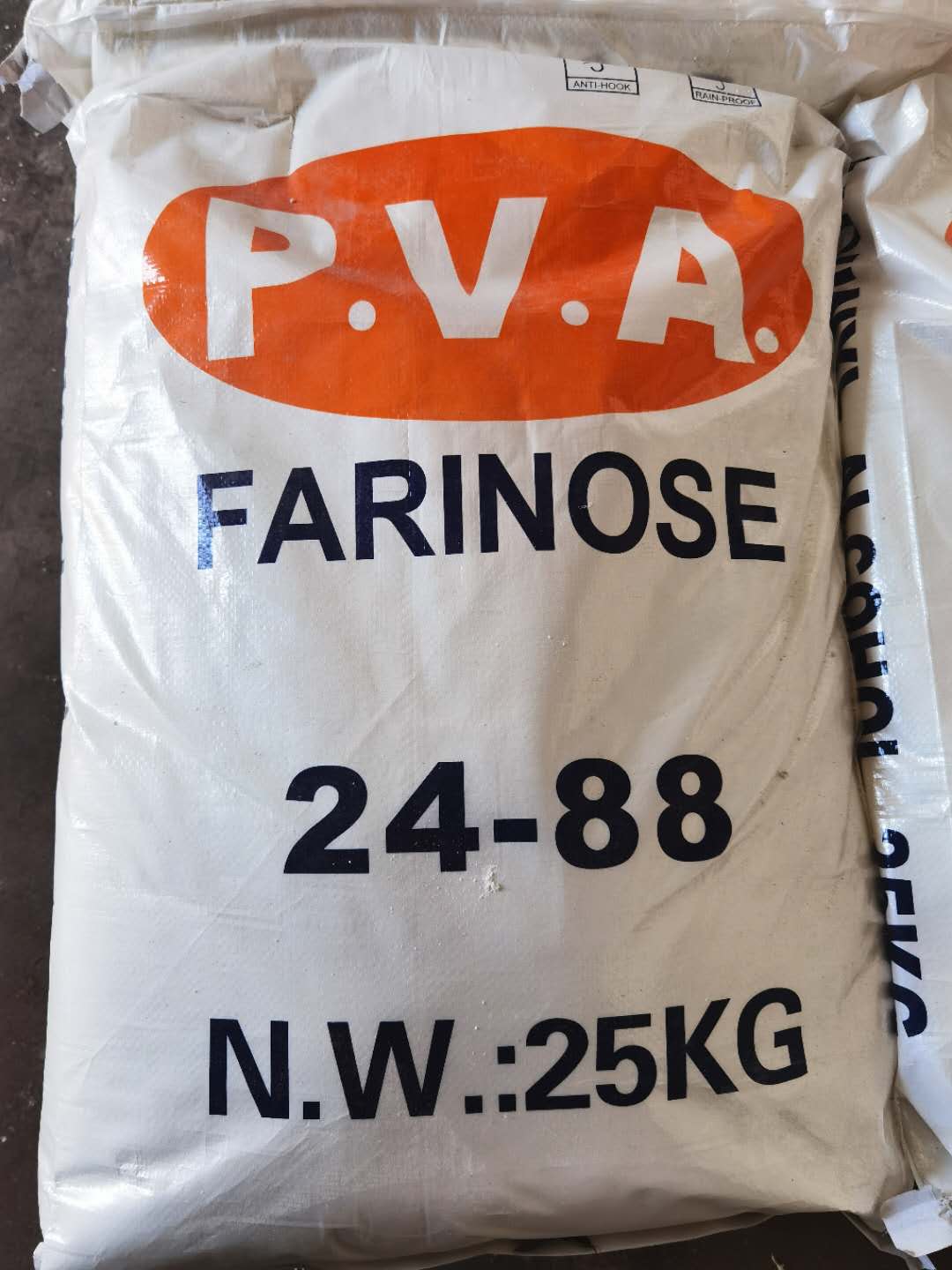

At present, PVA 17-88 and PVA 24-88 are the most widely used PVA products. PVA 17-88 indicates that the polymerization degree of the product is 1700 and alcoholysis degree is 88%. PVA 24-88 indicates that the polymerization degree is 2400 and alcoholysis degree is 88%. Generally speaking, the greater the degree of polymerization, the greater the water-soluble viscosity, the better the strength and solvent resistance of the film, the greater the degree of alcoholysis, the lower the solubility in cold water, and the higher the solubility in hot water. Therefore, the Picture 4.11-1 lists the product characteristics of PVA 24-88.

| Viscosity(MPa.s) | 43~48 |

| Volatile matter,wt% | Less than 5% |

| Ash content,wt% | 0.5% |

| pH | 5~7 |

| Average polymerization degree | 2400~2500 |

| Alcoholysis degree(%) | 88% |

| Molecular weight: | 117000~122000 |

| Particle size (mesh) | 80~120 |