At the Fraunhofer WKI, researchers have developed a flax leno fabric with a bio-based coating as the foundation for a natural-fiber reinforcement. The renewable natural fibers are available regionally or Europe-wide – and a partially bio-based coating contribute towards improving the carbon footprint of the construction industry.

Textile-reinforced concrete components with a sustainable natural-fiber reinforcement possess sufficient bond and tensile load-bearing behavior for the utilization in construction. This has been verified by researchers at the Fraunhofer WKI in collaboration with Biberach University of Applied Sciences and the industrial partner Fabrino. In the future, textile-reinforced components with natural-fiber reinforcement could therefore replace conventionally reinforced concrete components and improve the environmental balance in the construction industry.

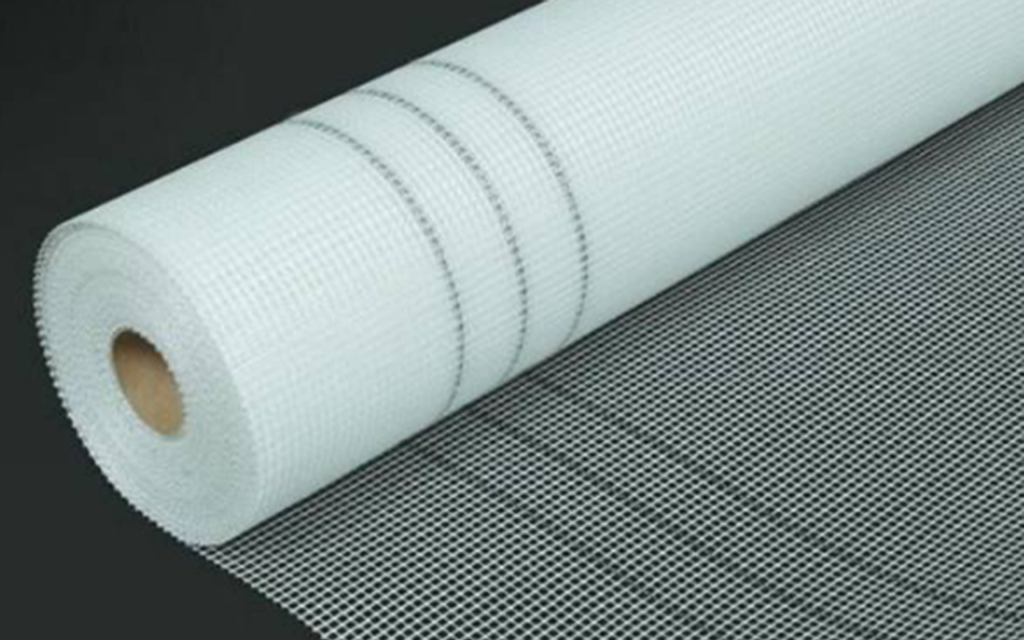

Non-metallic reinforcements for concrete elements are currently often made from various synthetically produced fibers – for example from glass or carbon fibers. An ecological alternative to synthetic fibers is provided by flax or other natural fibers. These are widely available and are highly sustainable, due, amongst other things, to their renewable raw-material basis, the advantages regarding recycling, and the lower energy requirements during production. This is where the researchers from the Fraunhofer WKI and Biberach University of Applied Sciences, in collaboration with an industrial partner, became active. Their goal was to demonstrate that reinforcements made from textile fibers are just as suitable for utilization in construction as synthetic fibers.

“At the Fraunhofer WKI, we have produced leno fabrics from flax-fiber yarn using a weaving machine. In order to enhance sustainability, we tested a treatment of the flax yarns for improving the tensile strength, durability and adhesion which is ecologically advantageous compared to petro-based treatments,” explained Jana Winkelmann, Project Manager at the Fraunhofer WKI. In the coating process, a commonly used petro-based epoxy resin was successfully replaced by a partially bio-based impregnation.

At Biberach University of Applied Sciences, researchers tested the bond and tensile load-bearing behavior as well as the uniaxial flexural load-bearing behavior of concrete components with textile reinforcement made from flax fibers. The scientists came to the conclusion that the natural-fiber-based textile-reinforced components with a bio-based impregnation are fundamentally suitable. The suitability was demonstrated by both a significant increase in the breaking load compared to non-reinforced and under-reinforced concrete components and in finely distributed crack patterns.

As a whole, regionally or Europe-wide available, renewable natural fibers and a partially bio-based coating contribute towards an improvement of the CO2 footprint of the construction industry. As a result, a further opportunity is being opened up for the energy- and raw-material-intensive construction industry in terms of meeting increasingly stringent environmental and sustainability requirements. “Textile-reinforced concretes enable lighter and more slender structures and therefore offer architectural leeway. We would like to continue our research into the numerous application possibilities of natural-fiber-reinforced concretes,” said Christina Haxter, a staff member at the Fraunhofer WKI.