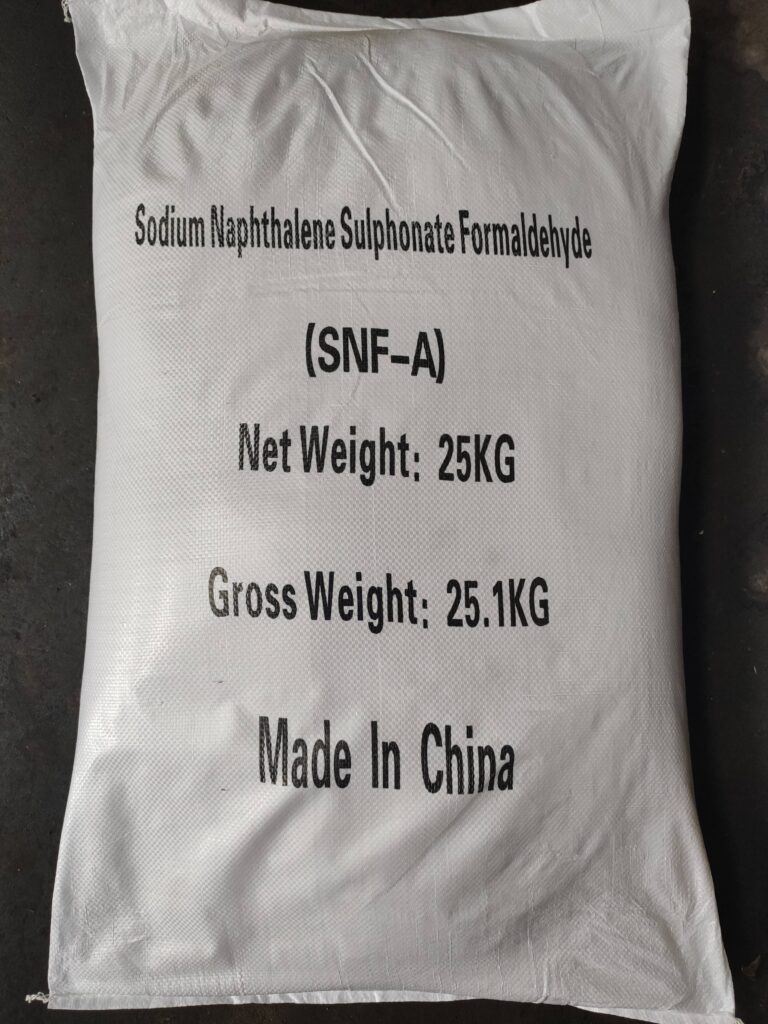

Naphthalene-based Superplasticizer

Naphthalene-based Superplasticizer

Naphthalene-based Superplasticizer has a high water-reducing rate, good fluidity, slight slump loss over time, and no segregation or bleeding. Meanwhile, it can significantly improve the fluidity and strength of concrete at all ages, especially the later potency, which has a significant enhancement effect. It is the first choice for admixture for high-strength concrete, commercial concrete, earthquake-proof concrete, self-leveling grouting materials, and other products.

Range of application:

- Suitable for concreteconstructed under hot temperature conditions, such as large-volume concrete, and cast-in-place piles;

- Suitable for sliding form constructedconcrete, pumping concrete, and fly ash concrete;

- Can be configured with various grades of concrete from C15 to C45.

Product model

| Model | Solid Content | Sodium Sulfate Content | Fluidity Of Cement Slurry | Water-Reducing Rate |

| SNF-5 | ≥91 | ≤5% | ≥200 | ≥18 |

| SNF-18 | ≥91 | ≤18% | ≥180 | ≥16 |

Performance features:

- Theproduct is non-toxic, non-flammable, stable in shape, and has no corrosion effect on steel bars;

- The air content is 2.5-4.0%, which is conducive to pumping construction;

- The sodium sulfate content is ≤18%with low alkali content, and it will not cause an alkali-aggregate reaction;

- The water-reducingrate is 12-20%, which can increase the fluidity of the mixture, and the concrete slump reaches 15-20cm; the loss in 60 minutes is ≤20mm, which is suitable for the continuous pouring of large volumes of concrete in hot seasons, reducing hydration heat and reducing the temperature stress to avoid the occurrence of temperature difference cracks;

- Increase the compactness of concrete, reduce shrinkage, improve the durability of concrete, and extend its service life.

The disadvantage of the Naphthalene-based Superplasticizer is poor slump retention performance. However, mixed with retarders (sodium tripolyphosphate, sodium citrate, potassium sodium tartrate, sodium gluconate, and sucrose) can reduce slump loss. It can also be compounded with lignin sulfonate to maintain certain air entrainment and reduce concrete slump loss.

Recommended dosage:

Powder products are generally 1.2-3.0%,

Liquid products are generally 1.2-3.0%.

Instructions:

- Adjust the dosage after testing according to project requirements;

- Generally add it to the mixer simultaneously with the mixing water. The plasticizing effect is best if it is delayed or stirred before concrete pouring and stirring slightly.

- To ensure the best use effect, it is recommended that before using this product for the first time or changing cement varieties in a project, users should conduct a trial mixing test to determine the optimal dosage and mixing method according to the project’s specific conditions.

Packaging and storage:

- Powder products are 25kg/bag.

- It should be stored in a cool and dry place, away from direct sunlight.

- The shelf life is one year. Confirmed through experiments before use if expired.

Related Products

Sodium gluconate

Retarder