High-Performance Dry Mortar

Dry mortar is a building material composed of precisely proportioned and industrially blended components such as cementitious materials (e.g., cement), aggregates, mineral admixtures, and functional additives. To meet the diverse performance requirements of modern construction, the selection of additives is particularly critical. Cellulose ether, a high-molecular-weight polymer derived from natural cellulose through alkali treatment and etherification, has become an indispensable functional additive in dry-mix mortar. It primarily functions to enhance water retention, increase viscosity, and improve workability.

This paper systematically analyzes the effects of cellulose ether on mortar water retention, rheological properties, and workability through comparative experiments, providing a reference for engineering applications.

Experimental Design

1.1 Materials and Instruments

Binding Material: PII 42.5 Portland Cement

Aggregate: ISO Standard Sand, screened to exclude particles >1.0 mm

Additive: Methylcellulose(MHEC/HPMC)(Model: MP 07N01)

Experimental Equipment: Cement mortar mixer, jump table, measuring cylinder, gel time ring, filter paper, etc.

1.2 Test Mix Proportions and Preparation

Two comparative test groups were established:

Experimental Group (1#): Cement : Sand : Cellulose Ether : Water = 350 : 650 : 2 : 220

Control Group (2#): Cement : Sand : Water = 350 : 650 : 220

Dry materials were thoroughly premixed according to the ratios, then water was added and stirred to form mortar for later use.

Performance Testing and Results Analysis

2.1 Water Retention

Water retention performance was tested using the filter paper method. Results showed:

Group 1 (with cellulose ether): No significant water marks appeared on the filter paper after 30 minutes, indicating slow internal water migration and excellent water retention.

Group 2 (without cellulose ether): Noticeable water stains appeared on the filter paper within 1 minute, indicating rapid water bleeding and poor water retention.

Mechanism Analysis: Cellulose ether molecules contain numerous hydrophilic groups that form a three-dimensional network structure in the hydration environment. This effectively retards water evaporation, prolongs cement hydration time, enhances strength development after mortar hardening, and reduces cracking risks.

2.2 Thickening Properties

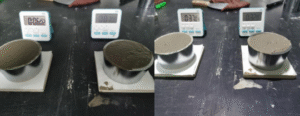

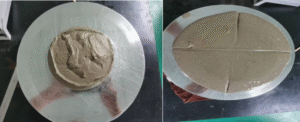

Mortar flowability was evaluated via the flow-table test:

Mortar flowability was evaluated via the flow-table test:

Group 1: Spread values of 157–159 mm indicated relatively high viscosity, suitable for thick-layer application and vertical surfaces.

Group 2: Spread values reached 256–258 mm, exhibiting excessive flowability prone to segregation and bleeding.

Mechanism Explanation: Cellulose ether interacts with water molecules and cement particles via hydrogen bonds, significantly increasing paste viscosity and imparting excellent structural stability and sag resistance to the mortar.

2.3 Workability

Group 1: Mortar with cellulose ether addition: Exhibited superior workability, adhesion, and sag resistance.

Group 1: Mortar with cellulose ether addition: Exhibited superior workability, adhesion, and sag resistance.

Group 2: Mortar without cellulose ether: Exhibited noticeable segregation, settling, bleeding, weak bonding strength, and poor workability.

Conclusion

The above tests clearly demonstrate that adding cellulose ether significantly enhances three key properties of dry-mix mortar:

The above tests clearly demonstrate that adding cellulose ether significantly enhances three key properties of dry-mix mortar:

Water retention: Slows water evaporation and bleeding, ensuring complete cement hydration;

Thickening: Optimizes rheological properties, improving mortar’s sag resistance and uniform application capability;

Workability: Enhances adhesion and cohesion, preventing separation and loose aggregate.

Therefore, cellulose ether serves as a crucial functional additive in high-performance dry-mix mortar formulations.