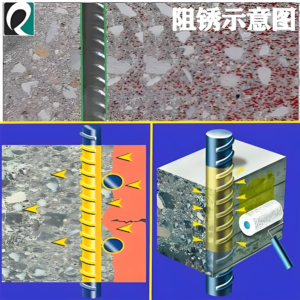

CORROSION INHIBITORS is an organic-inorganic composite high-performance concrete corrosion-resistant additive, specifically used for reinforced concrete buildings in chloride corrosive gas environments. This product can form a passive film and an adsorption film on the surface of concrete, wrapping the entire reinforced concrete with a layer of oxide passive film. It has good density and can effectively suppress the electrochemical reaction that causes steel corrosion in the long term, prevent chloride ions from penetrating, reduce the free rate of iron ions, alleviate the corrosion of harmful ions on steel bars in concrete, achieve the purpose of rust prevention and rust prevention, and thus extend the service life of concrete.

| CORROSION INHIBITORS | CIA24 | SD0130 | Dual action corrosion inhibitor, anodic and cathodic protection, reduced occurrence of corrosion, no calcium nitrite | Liquid | 10–12 kg/m³ | ferrogard 901s |

| CNI | SD0131 | CNI is a calcium nitrite-based corrosion inhibiting admixture containing a minimum of 30% calcium nitrite by mass. | Liquid | 10–12 kg/m³ | CNI |

Benefits:

- Extends the service life of concrete structures.

- Reduces maintenance and repair costs.

- Improves durability, especially in marine, coastal, or chemically aggressive environments.

Application:

- Added to concrete during mixing for internal protection.

- Applied as surface coatings or treatments for existing structures.