Shrinkage Reducing Admixture are special chemical additives used in concrete to minimize the extent of shrinkage that occurs as the concrete hardens and dries. Shrinkage can cause cracking, reduce durability, and compromise the structural integrity of concrete structures. SRA is an innovative liquid chemical admixture that is specifically formulated to reduce drying shrinkage. Compared to normal concretes, It provides enhanced performance through a significant reduction in shrinkage strain and a reduced number of harmful cracks.

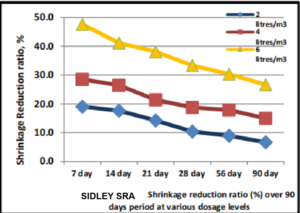

| Shrinkage Reducing Admixture | SRA | SD0132 | Drying shrinkage reducing admixture, suitable for high performance concrete, reduces formation of cracks | Liquid | 2.0-6.0 L/m3 | control 40/masterlife sra 25 |

| SR-100P | SD0021 | Drying shrinkage reducing admixture, suitable for high performance concrete, reduces formation of cracks | Powder | 0.2 – 2.0% of cement (binder) | PSR 100 | |

| CRA | / | Plastic shrinkage reducer, reducing plastic shrinkage cracks | Powder/Liquid | 5.0-10.0 L/m3 | Life CRA 007 |

Benefits:

- Significantly reduce plastic shrinkage cracks during the initial setting phase.

- Minimize drying shrinkage over time.

- Improve durability by preventing crack formation.

Usage:

- Usually added during batching or mixing.

- Proper dosage is key to achieving desired Shrinkage Reducing Admixture.

Additional Notes:

- Shrinkage-compensating concrete can also be used, which incorporates expansive cement to counteract shrinkage strains.