Sodium Carboxy Methyl Cellulose (CMC)

CAS:9004-32-4

Brief Introduction

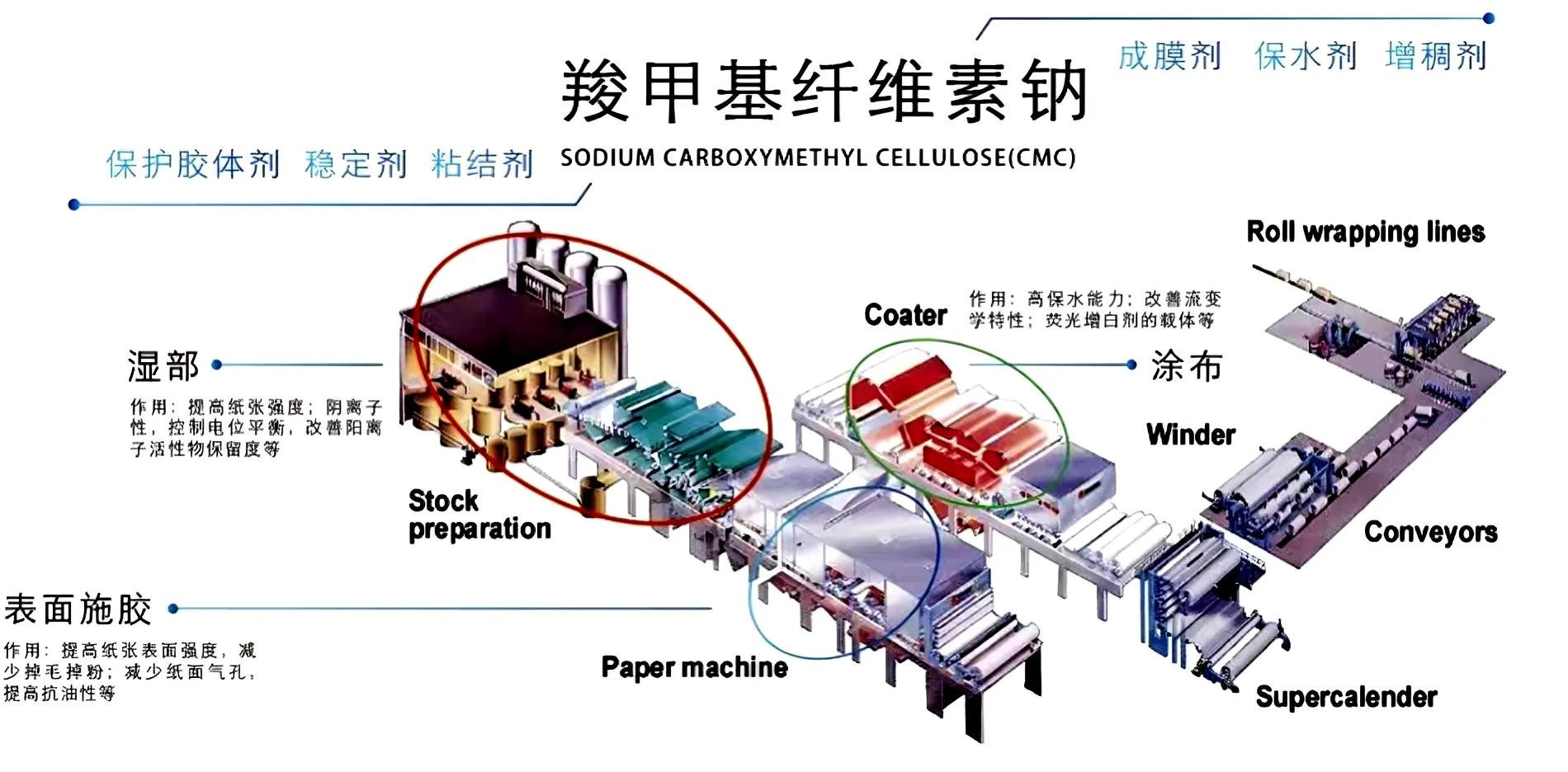

SidleyCel® Sodium CarboxyMethylCellulose (CMC) is anionic cellulose ether made from cotton fiber by alkalization, etherification, purification, drying, grinding or granulation. It has the appearance of white powder or granules and the colloid solution has functions like thickening, stabilizing, emulsifying, suspending, film-forming etc. CMC is widely used in food, toothpaste, paper making, ceramics, printing and dyeing, oil drilling and other industries.

| SdielyCel | Viscosity | Degree of Substitution | Purity % | Applications |

| 10FL30 | 20-40CPS(2%.25℃) | ≥1.0 | 99.5 | Lactic beverage;Yogurt |

| 9FM500 | 500-1000CPS(1%.25℃) | 0.85-0.95 | 99.5 | Juice |

| 7FH3000 | 3000-4000CPS(1%.25℃) | 0.75-0.85 | 99.5 | Plant-based beverage |

| 7FH5000 | 5000-6000CPS(1%.25℃) | 0.75-0.85 | 99.5 | Ice cream |

| 7FH7000 | 7000-8000CPS(1%.25℃) | 0.75-0.85 | 99.5 | Ice cream |

SidleyCel® CMC has benefits like good acid resistance, salt tolerance, high transparency, less free cellulose and gel particles, fast dissolution and good fluidity.

- CMC can prevent the protein in yoghurt from coagulating and delamination.

- CMC can make water, fat and protein well mixed, dispersed and emulsified in ice cream, avoid ice crystals, improve taste and keep uniformity of final products.

- CMC can ensure the stability of acid drinks and extend its shelf life due to its good degree of substitution.

- CMC itself has no calorific value and is a good choice for manufacturing low-calorie foods.