Ground Granulated Blast-furnace Slag

Ground granulated blast-furnace slag

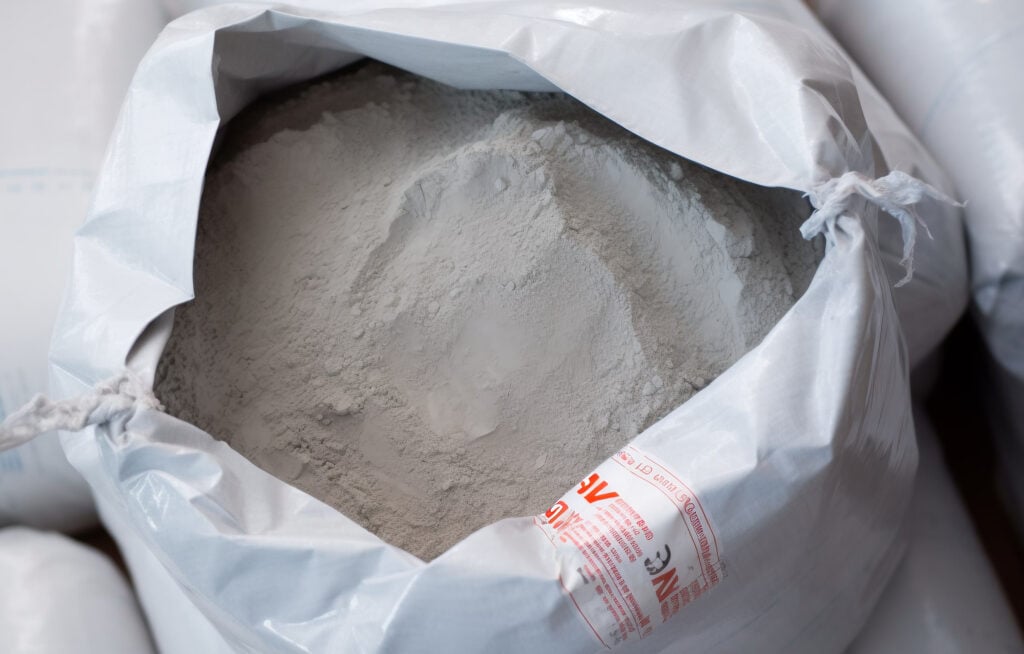

Among the three major cementitious materials in concrete, Ground granulated blast-furnace slag(GGBFS/GGBS) is the full name. Granulated blast furnace slag is produced during the smelting of pig iron in a blast furnace (commonly referred to as slag). It is a molten material primarily composed of silicates and aluminosilicates. When rapidly quenched with water at high temperatures, it forms a fine-grained vitreous substance before crystallisation can occur.

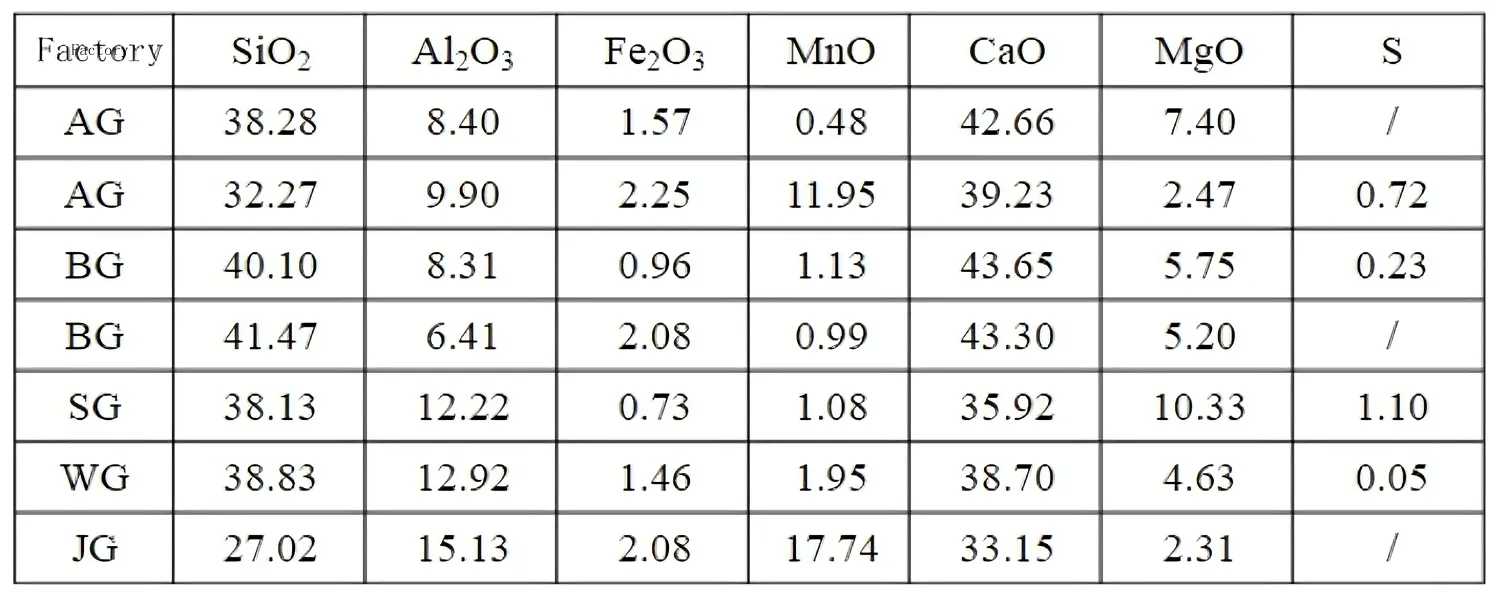

Chemical Composition of Blast Furnace Slag

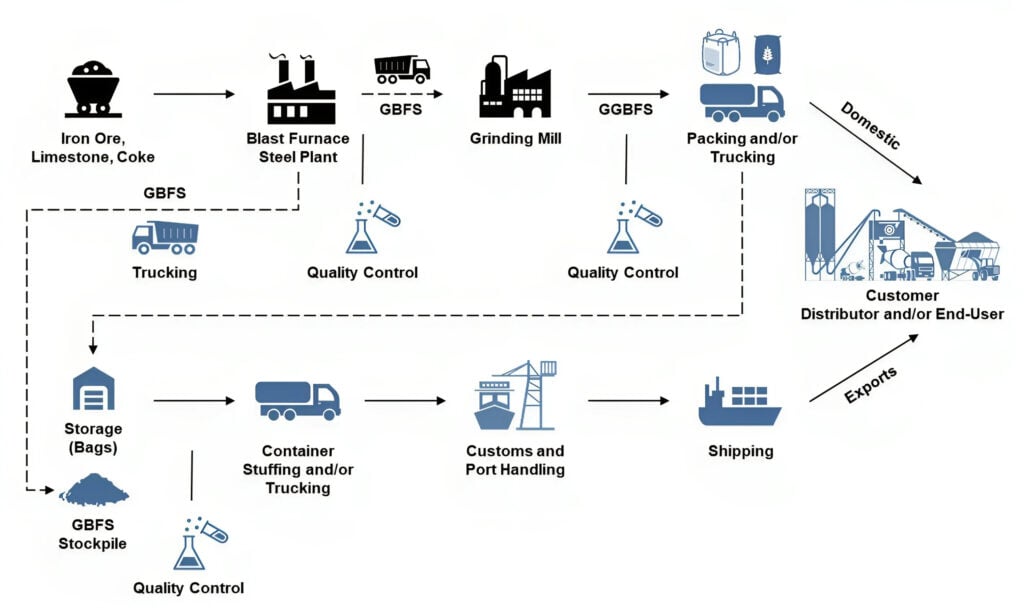

Production Process of Ground Granulated Blast-furnace Slag

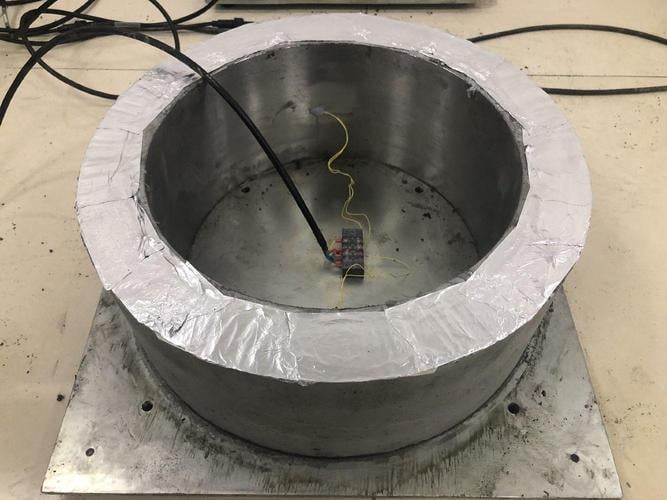

During the blast furnace ironmaking process, in addition to iron ore and fuel (coke), appropriate quantities of limestone and dolomite are added as fluxing agents to reduce smelting temperatures. The calcium oxide and magnesium oxide released from their decomposition within the blast furnace, combined with waste minerals from the iron ore and ash from the coke, fuse together. This forms a molten mass primarily composed of silicates and aluminosilicates, which floats on the surface of the molten iron. It is periodically discharged through the slag tap hole, then rapidly cooled using air or water to form granular particles – this is the slag. Containing over 95% glass phase and dicalcium silicate, along with minerals such as orthoclase feldspar and wollastonite, the slag composition closely resembles cement. If not water-quenched, the slag exhibits stable crystalline mineral forms, with only a small portion of dicalcium silicate possessing hydration activity. This process can be understood as ‘sealing’ a certain amount of energy within the slag through rapid water quenching. This ‘energy’ (reactivity) can be activated under alkaline conditions. Higher slag discharge temperatures and faster cooling rates yield greater potential chemical energy within the vitrified slag. Each tonne of pig iron produced generates 0.3 to 1 tonne of slag. After water quenching, the slag undergoes a grinding process to produce the slag powder used in concrete mixing plants.

Properties and Applications of GGBFS

Substituting a proportion of clinker or cement with mineral powder can produce effects such as the ‘pozzolanic effect’, thereby enabling complementary properties among various raw materials. This approach not only effectively utilises waste slag from steel mills but also reduces production costs for cement or concrete. For Portland blast-furnace slag cement Type B*, GGBFS also contributes to decarbonization, reducing CO2 emissions by 42% per ton of cement.

* Portland blast-furnace slag cement Type B is a category of cement defined in Japanese Industrial Standards (JIS)

Characteristics of Ground Granulated Blast-furnace Slag

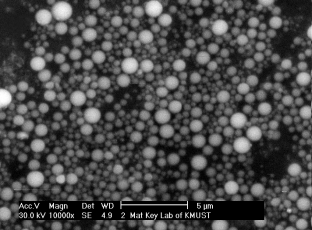

GGBFS possesses latent hydration activity. When mixed with cement, the calcium hydroxide produced during cement hydration can activate the GGBFS. This enables the GGBFS to undergo hydration reactions, forming calcium silicate hydrate which fills the pores within the cement concrete. This significantly enhances the density of the cement concrete while simultaneously converting the lower-strength calcium hydroxide crystals into the higher-strength calcium silicate hydrate gel.

The Influence of Chemical Composition in Slag on Reactivity

- Calcium oxide, an alkaline oxide, constitutes the primary chemical component of slag, typically accounting for approximately 40%. It exists within slag in the form of silicates, such as dicalcium silicate, which possesses reactivity. Consequently, calcium oxide is the principal factor determining slag reactivity; the higher its content, the greater the slag’s reactivity.

- Alumina is an acidic oxide and constitutes a favourable active component within slag, existing in the form of aluminates or aluminosilicates. Its content typically ranges from 5 to 15 per cent, though concentrations as high as 30 per cent may occur. Silica, a mildly acidic oxide, is present in slag at approximately 30 to 40 per cent. Compared to calcium oxide and alumina, it diminishes the slag’s reactivity.

- Magnesium oxide exhibits lower reactivity than calcium oxide, typically present at 1%–18%. Within slag, it exists as stable compounds or vitrified phases, causing no instability or adverse effects. Consequently, magnesium oxide is generally regarded as the reactive component of slag.

- Manganese(II) oxide poses no threat to cement soundness but does affect slag reactivity. Its content should be controlled between 1% and 3%; exceeding 4%–5% will markedly reduce slag reactivity.

- The presence of sulphur causes some loss of cement strength; however, calcium sulphide reacts with water to form calcium hydroxide, which provides an alkaline stimulation effect.

- Titanium oxide reduces slag reactivity; standards stipulate its content must not exceed 10%.

Applications of Ground Granulated Blast-furnace Slag

When blended in proportion with Portland cement, it produces high-performance GGBFS cement. GGBFS with a fineness of 400–450 m²/kg may be used to formulate ordinary Portland cement grades 425 and 425R.

As a concrete admixture, it enhances concrete strength and durability.

Ground Granulated Blast-furnace Slag effect

- Effectively enhances concrete’s resistance to seawater erosion, particularly suitable for marine engineering projects;

- Significantly reduces hydration heat in concrete, making it suitable for mass concrete applications;

- Effectively suppresses alkali-aggregate reactions in concrete, enhancing durability;

- Markedly reduces bleeding issues in concrete, improving workability;

- Substantially increases concrete strength;

- Enhances concrete compactness, improving impermeability;

- Reduces concrete production costs;

Simply adding Ground Granulated Blast-furnace Slag to concrete reduces early strength but benefits later strength. Ground Granulated Blast-furnace Slag enhances early strength only under specific conditions, such as high-temperature curing or the addition of lime powder, whilst the proportion replacing cement must remain within reasonable limits. Therefore, pairing it with a high-performance polycarboxylate superplasticiser is particularly crucial. We recommend the functional superplasticiser: PCE1056L.