Drilling mud is an engineered fluid employed in drilling operations, extensively utilised during petroleum, natural gas, and geothermal well drilling. It constitutes a multiphase fluid system formulated from a base fluid (typically water or oil/synthetic solvent) combined with various chemical and solid additives. This system performs critical functions including regulating rheological properties, transporting cuttings, balancing formation pressure, cooling and lubricating the drill bit, controlling fluid loss, and providing cementing protection.

Drilling mud is the lifeblood of well operations. The success of each well requires a suitable mud system, excellent mud properties, and correct, rational drilling techniques working in concert. Mud operations necessitate coordination with drilling procedures, while drilling procedures depend on mud maintenance. The two are intrinsically linked and mutually dependent.

Firstly, the mud must possess excellent rheological and thixotropic properties to meet the demands of cuttings transport and pumping pressure; Maintain minimal unnecessary low-density solid content (low-solid non-dispersive systems <4%) to reduce tool and equipment wear while enhancing drilling rates; Sustain optimal mud cake quality to protect wellbore stability and downhole safety; Adjust mud suppression properties as required for smooth drilling operations. Ultimately, mud performance must be continuously adjusted and maintained according to formation variations and drilling demands to prevent all potential incidents.

Oildrilling Application

01What is Drilling Fluid (Drilling Mud)?

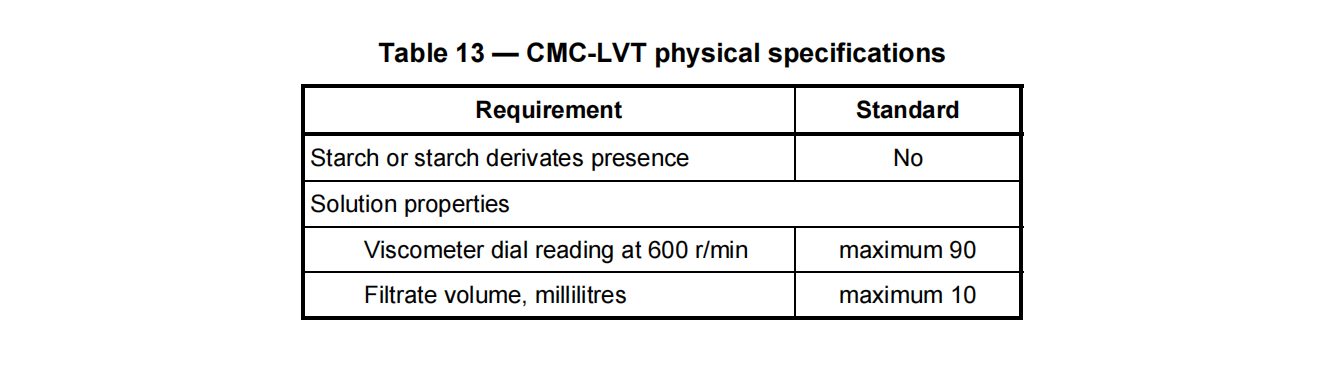

02Application of Sodium Carboxymethyl Cellulose in Drilling Fluids

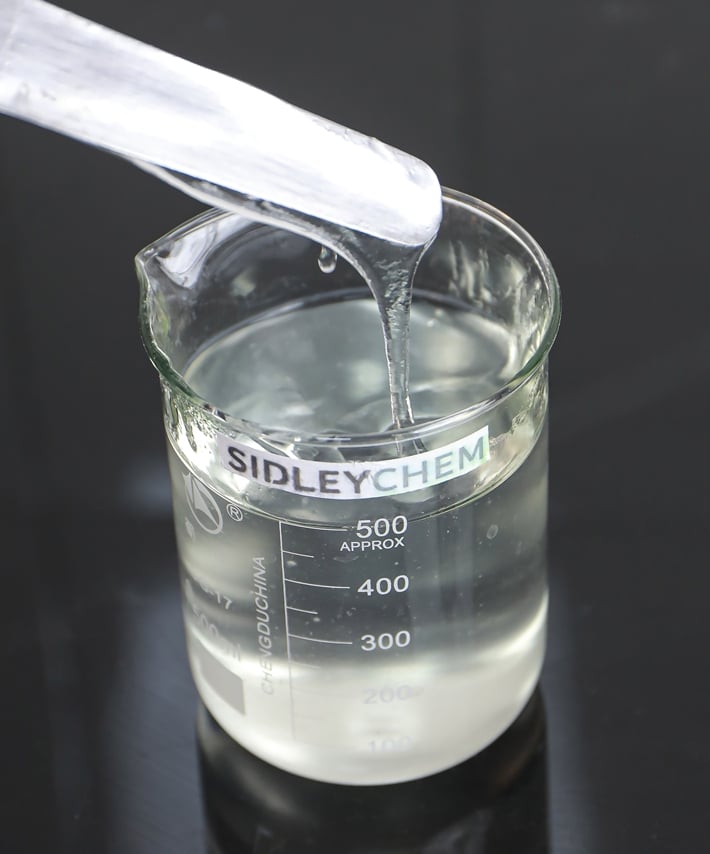

Sodium carboxymethyl cellulose is an anionic water-soluble cellulose ether exhibiting excellent water solubility, viscosity-enhancing properties, and film-forming capabilities.

Primary Functions and Mechanisms

1. Viscosity Enhancement and Rheology Modulation: CMC swells in water to form viscous solutions, increasing the plastic viscosity (PV) and yield point (YP) of drilling fluids. This enhances cuttings-carrying capacity and borehole wall support.

2. Filtration Control and Filter Cake Formation: CMC adsorbs onto solid particle surfaces, promoting fine particle packing and forming a dense filter cake, thereby reducing fluid loss into the formation (combined with starch, cellulose ethers, or cross-linked polymers for enhanced efficacy).

3. Suspension and Sedimentation Control: Improves suspension stability during static periods, reducing barite and drill cuttings sedimentation.

4. Rheology Modification and Lubrication Assistance: In certain systems, CMC combined with surfactants or lubricants can improve pumping performance and reduce friction.

5. Synergy with Particles and Other Polymers: CMC forms complementary networks with bentonite, starch, polyacrylamide (PAM), and other materials, enhancing mud cake quality and high-temperature stability.

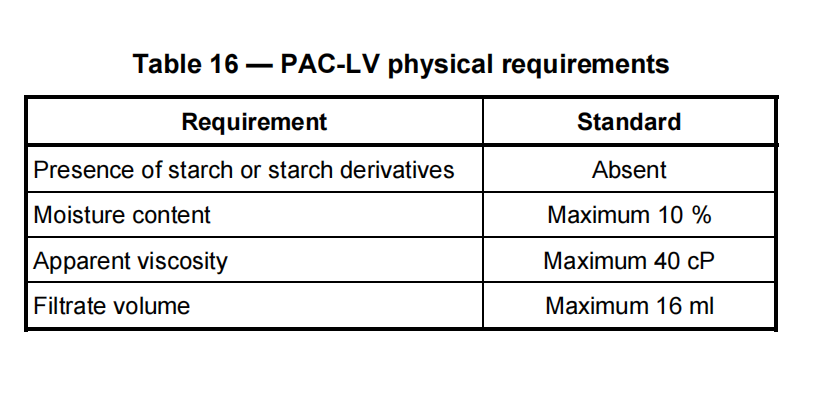

03PolyAnionic Cellulose, PAC

Polyacrylamide cellulose can be employed in most water-based drilling fluid systems, including freshwater, seawater, and salt cement slurries, with temperature resistance up to 150°C. PAC-HV aids in viscosity enhancement with minimal dosage. It is non-toxic and requires no biocides. PAC-HV also encapsulates drill cuttings and suppresses active shale dispersion, thereby enhancing wellbore stability.

Application Scope/Function

Effectively controls fluid loss and assists in viscosity enhancement

Facilitates the formation of a thin, resilient, low-permeability mud cake, reducing the risk of adhesion and stuck pipe

Minimises erosion of filtrate and mud solids

Advantages

Temperature resistance up to 150°C

Non-fermenting, eliminating the need for biocides

Suitable for freshwater, seawater, and salt cement slurries

Compatible with medium to high pH ranges

Coats shale to inhibit hydration expansion and dispersion

04HydroxyEthyl Cellulose

In oilfield applications, hydroxyethyl cellulose (HEC) demonstrates exceptional performance in drilling, completion, workover and fracturing processes, primarily serving as a thickening agent in brine solutions. HEC exhibits exceptional salt tolerance towards electrolytes. As a non-ionic material, it does not ionise in aqueous media and will not precipitate residues due to high salt concentrations in the system, thereby preventing viscosity alteration.

HEC thickens numerous high-concentration solutions of monovalent and divalent electrolytes, whereas anionic cellulose derivatives like CMC may precipitate certain metal ions. In oilfield applications, HEC remains entirely unaffected by water hardness or salt concentration, even thickening weighted fluids containing high zinc and calcium ions. Only aluminium sulphate causes precipitation.

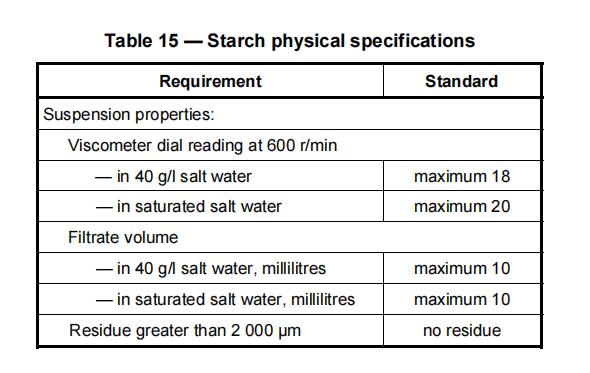

04Carboxymethyl Starch

High-temperature resistant carboxymethyl starch for drilling fluids is a water-soluble product obtained by alkalising starch followed by chloracetic etherification. It effectively controls fluid loss in both fresh and brine drilling fluids. This product offers advantages including easy degradation, non-fermentability, excellent temperature resistance, and minimal impact on drilling fluid rheology, making it an economical alternative to CMC and similar products.

Principal Properties and Characteristics of carboxymethyl starch:

1. When added to water or drilling fluid, this product disperses uniformly and dissolves rapidly. It exhibits no tendency to form lumps or fish-eye phenomena even without agitation, representing a significant distinguishing feature from other carboxymethyl starch products.

2. This product satisfies the low fluid loss requirements for 4% brine and saturated brine drilling fluids at ambient temperatures.