Disperse dye printing Thickener/paste is mainly composed of natural polymer substances, suitable for polyester knitted and woven fabrics with disperse dye printing, the paste as the carrier of the printing dye paste plays a key role in the printing effect. This product has a high colour yield and can be used to print polyester fibres with a soft hand and clear pattern. It can be mixed with a small amount of disperse thickener to reduce costs.

| DS-101 | >10000,(5%) | Low amount, high clarity, good handfeel; suitable for fine and large-area printing |

Functions of Screen Printing Thickeners

- Viscosity: Provide the right thickness for controlled, precise printing.

- Adhesion: Help the dye or pigment adhere to the fabric.

- Film Formation: Ensure the design remains sharp during and after washing.

- Prevent Bleeding: Limit spreading of dyes or pigments.

Disperse dyes are a class of insoluble dyes primarily used for printing on synthetic fibers like polyester, acetate, and nylon. They are characterized by their ability to disperse in water and form a dye bath or paste, which adheres to the fibers through heat fixation.

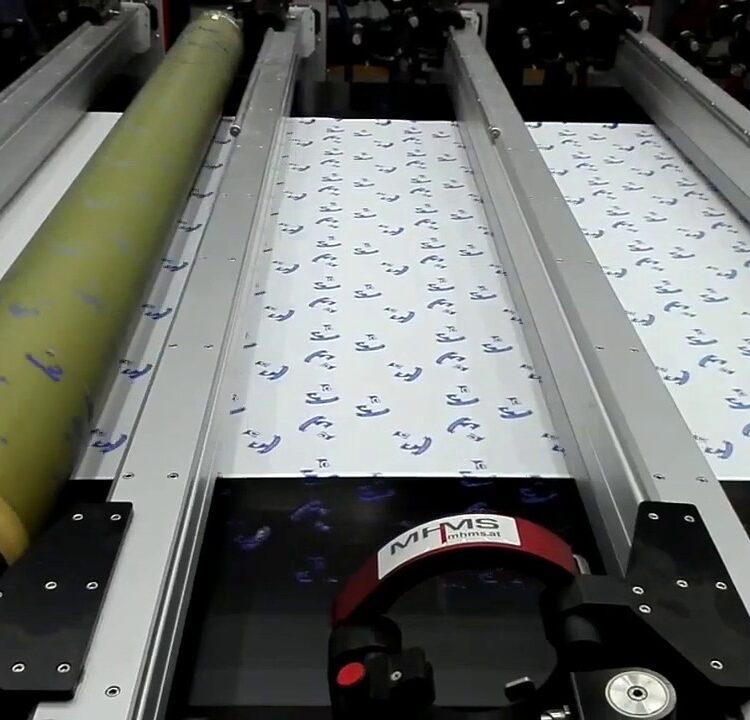

Disperse Dyes Screen Printing

What Are Disperse Dyes?

- Insoluble in water: They are finely ground powders dispersed in water with the help of dispersing agents.

- Affinity: They have a high affinity for synthetic fibers, especially polyester.

- Color Range: Available in a wide range of vibrant colors and shades.

Screen Printing Process with Disperse Dyes

1. Fabric Preparation:

Clean and treat the fabric, typically polyester, to remove impurities and enhance dye fixation.

2. Preparation of Printing Paste:

- Disperse dyes are mixed with DS-101 thickeners (such as cellulose derivatives or gums).

- Dispersing agents and surfactants may be added to maintain uniform dispersion.

- The paste should have the right viscosity for printing (similar to reactive dyes but often more viscous).

3. Screen Printing:

- The paste is applied via screen or roller printing methods to the fabric.

- Precise control over the application ensures clear, sharp designs.

4. Fixation (Heat Thermofixation):

- The printed fabric is subjected to heat in a heat press or oven, typically at 180–220°C.

- The high temperature causes the dye to sublime and fix onto the fibers through physical adhesion and diffusion.

5. Washing:

- A subsequent wash removes unfixed dye, leaving vibrant, wash-fast prints.

Advantages of Disperse Dyes Printing

- Vibrant Colors: Exceptional brightness and color depth.

- Fastness Properties: Good wash, light, and rubbing fastness when properly fixed.

- Excellent for Polyester: The primary dye used in polyester printing.

Disperse Dyes Screen Printing Paste Components

- Disperse dyes powder

- Thickener (cellulose derivatives or gums)

- Dispersing agents

- Surfactants

- Water