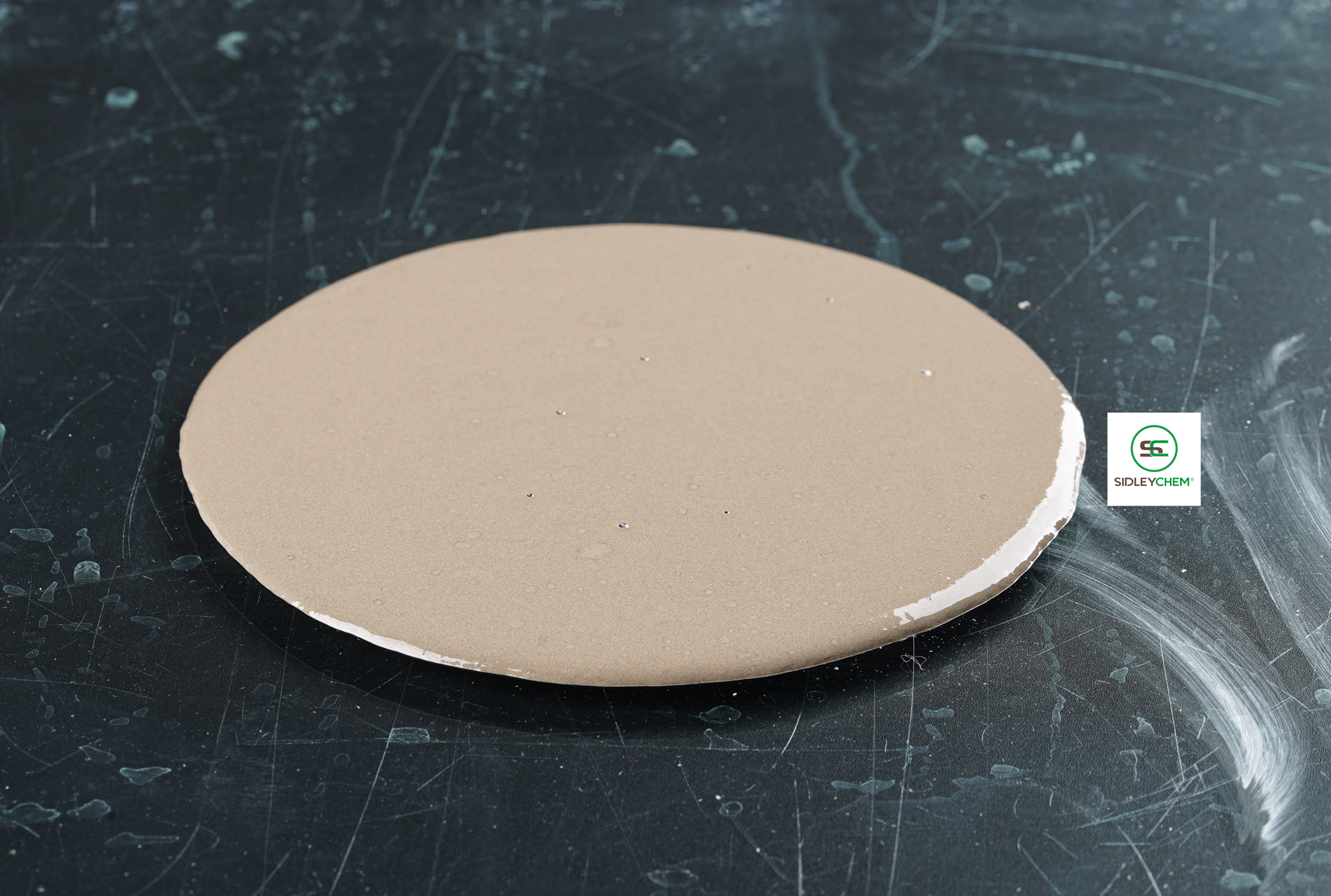

Concrete surface beautification is mainly achieved by utilizing the natural texture, texture, and color of concrete itself. It is a type of concrete that does not require any external decoration after pouring and forming. The surface effect is mainly achieved by carefully adjusting the proportion of concrete raw materials, strictly controlling the construction process, and beautifying various functional products.

| Product | Dosage | Benchmarking products | Product description |

| Finish RL99 | 10-30 m2/kg | Finish RL 211 or Separol | Ready-to-use Water emulsion form release agent for elements where excellent surface finish is important. |

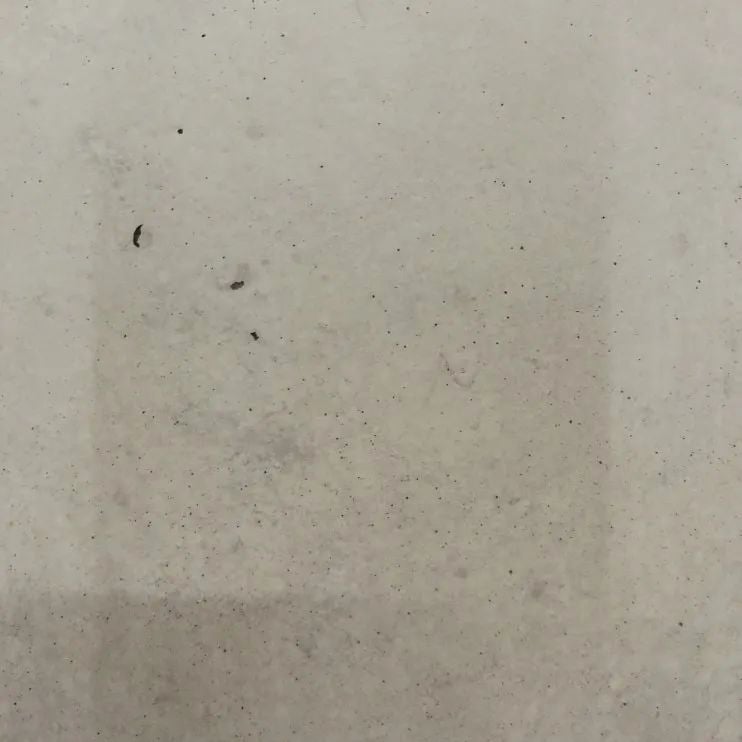

| Finish DF430 | 0.10 to 0.35 litres per 100 kg of cement (binder) | Finish DF 880 | Concrete defoamer for high-quality architectural concrete achieves a largely void-free surface in self-compacting and flowing concretes. |

| HC | 4-5 m2/ltr. | Antisol or Finish MPT 299 | Concrete curing agent to prevent the evaporation of moisture, allowing gases to pass through and facilitate respiration. |

| HCP | 4–7 m2/l/coat | CureHard-24 | Surface enhancers can penetrate into concrete, enhance surface strength, and prevent water evaporation. |

| TARD-S | 200 sq. ft. per gallon | Rugasol | Surface retarder, retard set of surface mortar in concrete, suitable for exposed aggregate surface, prevent cold joints. |

Main Functions:

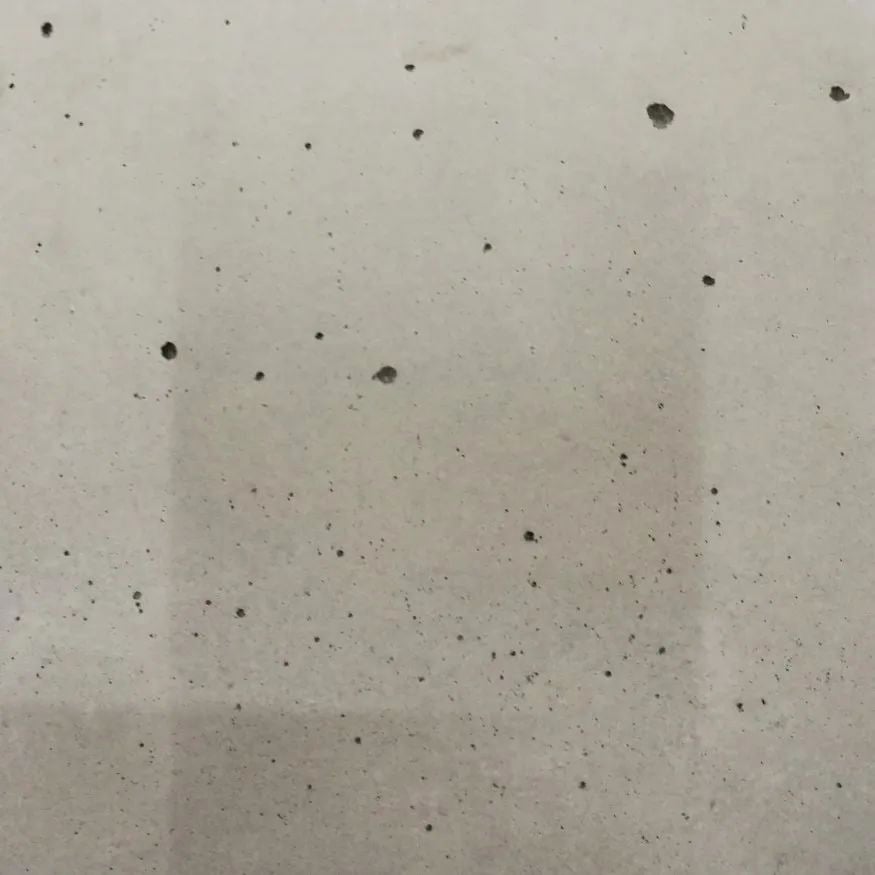

- Improve surface finish and appearance.

- Reduce water absorption and permeability.

- Enhance surface hardness and wear resistance.

- Protect against environmental damage and chemical attack.

Usage:

- Usually applied as surface treatments after concrete finishing.

- Can be used on new or existing concrete surfaces for repair or preservation.