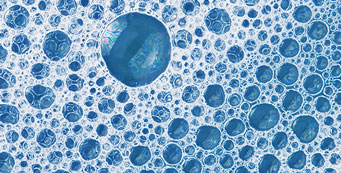

The hazards of foaming in water-based coatings!

In the production process of coatings, materials such as emulsions, dispersants, thickeners, leveling agents, wetting agents, and emulsifiers are actively used, causing the coatings to foam easily. Moreover, these bubbles have a stable and long-lasting effect. In particular, emulsifiers are added to water-based latex coatings, and the use of these emulsifiers can greatly reduce the surface tension of the emulsion system, causing bubble problems. At this time, a certain defoamer is needed to improve the situation.

Hazards of Foaming in Water-Based Coatings:

1. Air in the foam hinders the dispersion of pigments or fillers;

2. Foam reduces equipment utilization and affects production quality;

3. Foaming slows down mixing speed and extends mixing time;

4. Foam prevents pigments and fillers from being fully wetted;

5. It can also cause problems such as incomplete filling and uneven weight in continuous filling production lines.

6. Foaming can cause problems such as pits and small holes on the coating film during the use of water-based coatings.

What are the characteristics of a good defoamer?

1. Eliminate or inhibit the formation of foam:

Defoamers can cause bubbles to burst, thereby effectively reducing the formation of foam.

2. Improve coating fluidity:

Defoamers can significantly improve the fluidity of water-based coatings, making them smoother during spraying and brushing. This not only avoids uneven spraying caused by foam, but also improves construction efficiency and ensures the quality of the coating.

3. Enhance coating adhesion:

The use of defoamers can enhance the adhesion of coatings, reduce peeling and flaking of coatings, and thus extend the service life of coatings.

4. Improve the appearance of coatings:

By reducing the formation of foam, defoamers can prevent defects such as bubbles and holes on the coating surface, ensuring the smoothness and uniformity of the coating.

5. Improve the drying speed of coatings:

The use of defoamers can promote the rupture of bubbles, reduce the interference of bubbles in the drying process, and thus improve the drying speed and production efficiency of coatings.