Starch Ether can impart unique properties to cement and gypsum based products. It has the similar chemical structure with Hydroxypropyl Methylcellulose(HPMC) that not only provide Hydroxypropyl Methylcellulose(HPMC)-like function, but also has good compatibility with other building additives. In combination with Hydroxypropyl Methylcellulose(HPMC), Hydroxypropyl Starch Ether can play a better thickening effect, with better crack resistance and improve workability. And by adding starch ether, the cost of the mortar formulation can be significantly reduced.

| Type | Viscosity

(5% aqueous solution) |

Application |

| SE-301 | 1000-3000mPa.s | Tile Adhesive |

| SE-302 | 3000-6000mPa.s | Tile Adhesive |

| SE-501 | 1000-3000mPa.s | Wall Putty |

| SE-801 | 3000-6000mPa.s | Gypsum Plaster |

The properties of starch ether in dry mortar are as follows:

- Due to the special chemical structure of starch ether, Hydroxypropyl Starch Ether can effectively prevent the hanging phenomenon of thick layer of mortar, which has a good improvement effect on the sliding of the tile, the hanging of thick layer and other undesirable phenomenon;

- Adding appropriate amount of Hydroxypropyl Starch Ether in the mortar can delay the opening time of it. The water retention of starch ether can be kept stable with the increase of temperature. Therefore, the product can not only improve the water retention performance of the mortar, but also compensate the rapid retention of the water retention capacity of the ordinary water retention agent with the increase of the temperature;

- Hydroxypropyl Starch Ether has a fast thickening function for mortar, which can improve the rheology of spray mortar and plaster mortar;

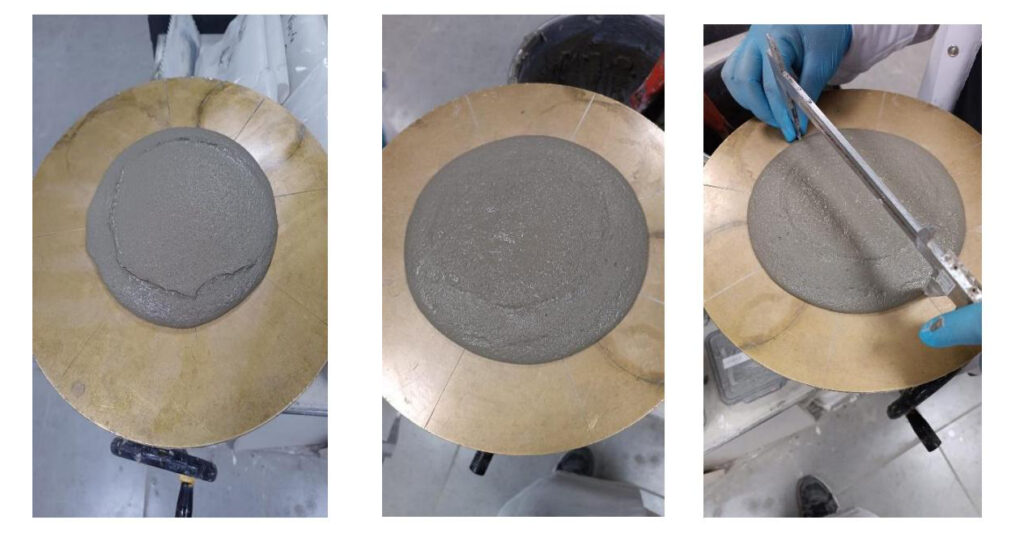

- Hydroxypropyl Starch Ether can effectively prevent the stratification/segregation of the mortar, which can be well used in self-leveling mortar;

The starch ether produced by Sidley Chemical can replace of international brand starch ether for Drymortar, it has excellent performance in mortar and can greatly reduce the cost.