coatings thickeners enhance application performance

In the process of coatings manufacturing and application, thickeners play an indispensable role. This special additive can effectively regulate the rheological properties of coatings, making them easier to apply while ensuring final coating quality.

Three Core Functions of Thickeners

Optimizing Application Viscosity

Thickeners improve the rheological characteristics of coating systems by increasing viscosity. Coatings with appropriate viscosity are easier to control during application, preventing dripping or sagging, especially on vertical surfaces. This not only enhances application efficiency but also reduces material waste.

Enhancing Adhesion

As coating viscosity increases, contact with the substrate becomes more sufficient, significantly improving adhesion. This means the coating can adhere more firmly to walls, wood, or metal surfaces, effectively preventing later issues like peeling or flaking, thereby extending the coating’s service life.

Improving Hiding Power

Thickeners help pigments and fillers disperse more evenly in the coating system, thereby enhancing hiding power. Good hiding power means fewer coating layers are needed to cover substrate imperfections and original colors, saving materials while ensuring a smooth, aesthetically pleasing finish.

Correct Usage Methods

To ensure thickeners deliver optimal performance, follow these steps:

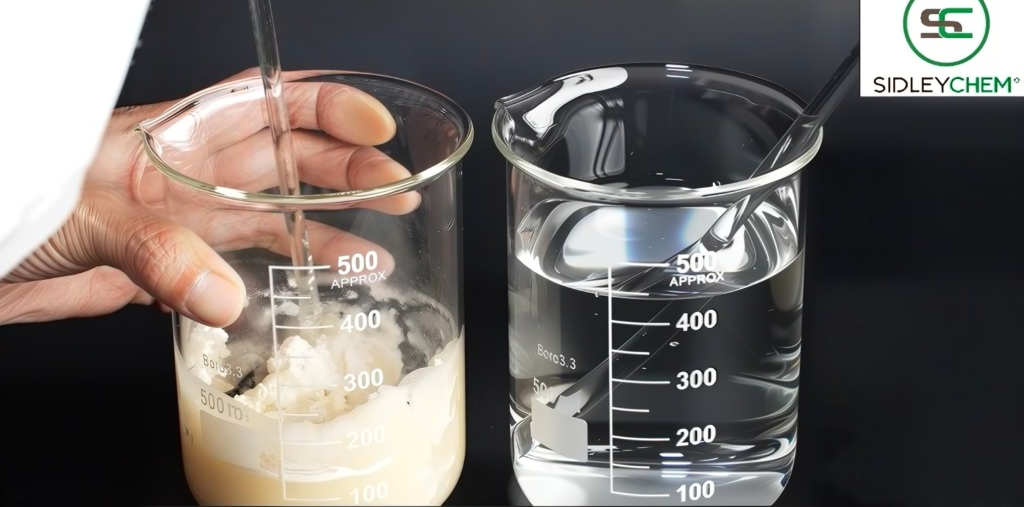

First, thoroughly stir the water-based coating before pouring it into a mixing container. Then slowly add the pre-calculated amount of thickener. Maintain continuous stirring during addition to ensure even dispersion of the thickener. Pay special attention to avoiding adding too much thickener at once – it should be added in batches, with thorough stirring after each addition while observing viscosity changes.

If viscosity becomes over-adjusted, appropriate amounts of water or emulsion can be added for dilution. The ideal final state is a coating with moderate viscosity, free of lumps or sedimentation, presenting as a uniform fluid.

Selection Recommendations

Different types of coatings require matching with corresponding types of thickeners. During actual selection, comprehensive consideration should be given to the coating’s composition system, application requirements, and expected results. Proper selection and use of thickeners can significantly enhance both the application performance and final film quality of coatings.

Through rational use of thickeners, both coating manufacturers and applicators can achieve better product performance and application experience, making this an important aspect for improving coating product competitiveness.