Tile adhesive is a specialised bonding material formulated with cement as its base, incorporating high-molecular polymers (such as polypropylene fibres or Redispersible Dispersible Polymer Powder), fillers (such as quartz sand), and additives (such as cellulose ethers or starch ethers). It is designed for the installation of ceramic tiles, stone, or mosaic.

Through chemical and physical interactions, tile adhesive forms a high-strength bonding layer. It is suitable for both wall and floor tiling applications, particularly for low-water-absorption tiles such as porcelain tiles and polished tiles.

TILE ADHESIVE

01What is tile adhesive?

02Standard and Formula

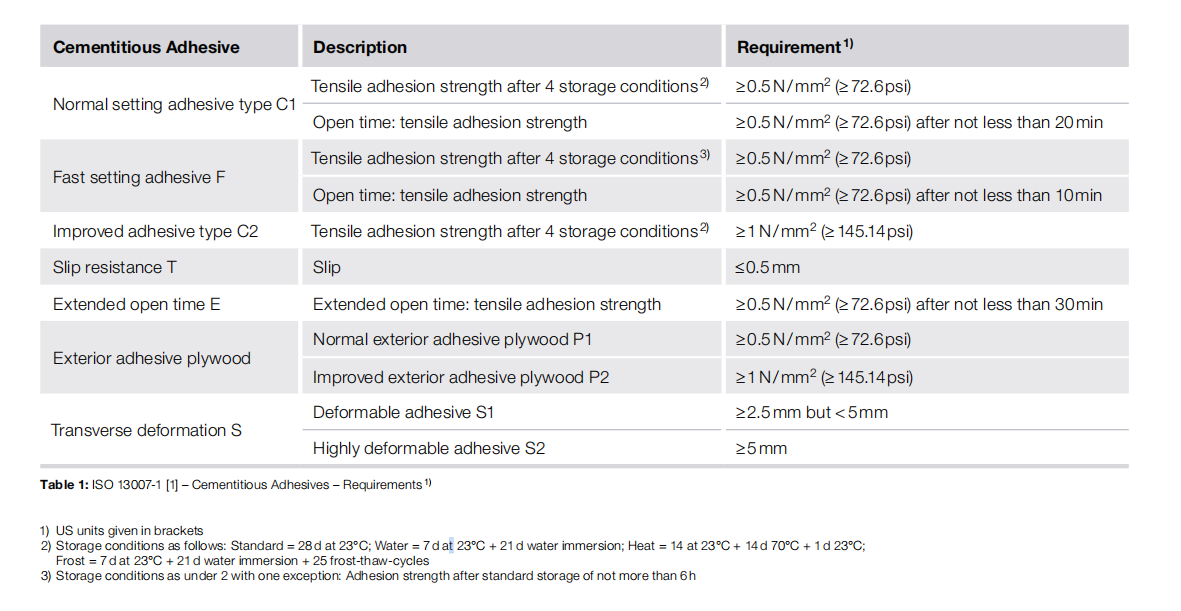

International standards for tile adhesives primarily include European Standard EN12004 and American Standard ANSI A118.1–4. These standards systematically test and classify tile adhesives according to their bonding strength, water resistance, freeze-thaw resistance, and workability.

Based on the EN standards the global standard ISO 13007 was implemented in 2005. The basic requirements were adopted from the European norms EN 12004 and EN 12002 . The long term goal of the International Standards Organization is the establishment of homogenized terminology and technical requirements which are adhered to by adhesive manufacturers around the world.

This standard imposes stringent requirements on the physical properties, chemical stability, and environmental adaptability of tile adhesives, such as:

- Bond strength must remain stable after immersion in water

- Heat resistance must maintain strength without degradation after 168 hours at 70°C

03Additives

SIDLEY’s additives deliver exceptional performance in tile adhesive applications. For tile adhesive: Cellulose ethers provide outstanding water retention performance and extended open time; offers excellent flexibility and strength alongside water repellency; Starch ethers deliver superior thickening and Sag resistance. We assist clients in resolving diverse tile adhesive challenges and provide tailored solutions.

04Additives Introduction and Recommended Types

- Cellulose ether exhibits outstanding thickening and water retention performance, maintaining water retention performance even during hot summers.

- Redispersible polymer powder exhibits outstanding film-forming properties, enhancing mortar strength and water resistance. High-quality redispersible polymer powder is a crucial component in tile adhesives.

- Specialty additives confer diverse functionalities to drymortar, such as improved flexibility, accelerated early strength development, and smoother workability.