Agglomeration Issue of HPMC

Recently, we received feedback from some customers that when producing water-based cosmetic products or coatings, directly adding hydroxypropyl methylcellulose (HPMC) powder often results in an agglomeration phenomenon and uneven dissolution. This article will start with a mechanism analysis and provide practical solutions to help you optimize your process and ensure product quality.

I. Why Does HPMC agglomerate?

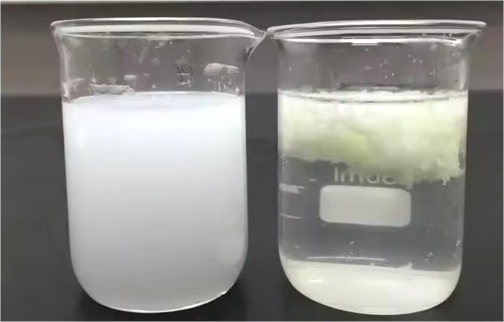

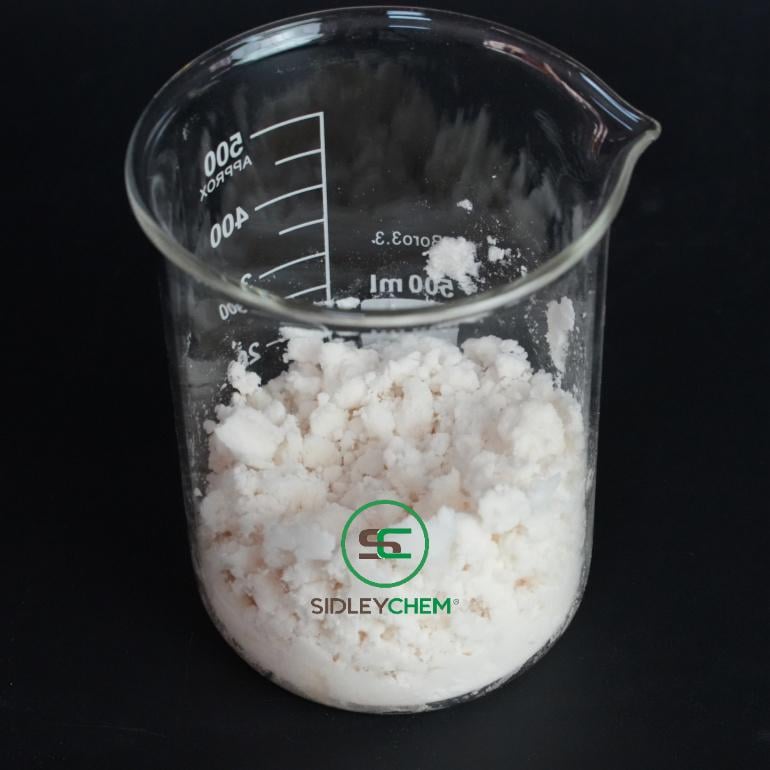

Agglomeration Phenomenon: When HPMC powder is directly and heavily introduced into a pre-mixed material batch, its outer layer instantly contacts a large number of water molecules, rapidly hydrating and swelling to form a dense gel layer. This gel layer encapsulates the inner dry powder, preventing further water penetration. This ultimately results in the formation of viscous gel lumps on the exterior while the interior remains dry powder—the phenomenon of agglomeration.

This not only severely impacts production efficiency but also prevents HPMC from dispersing uniformly and performing its core functions such as thickening and water retention, leading to inconsistent product performance between batches.

II. Solutions:

Solution 1: Adjust Addition Sequence (Recommended)

Steps:

- Add the majority of the total water required for the formulation first.

- While maintaining continuous, thorough mixing, slowly and evenly sprinkle in the HPMC powder.

- Continue mixing until the HPMC powder is completely dispersed in the water, forming a uniform solution with no visible particles.

- Add other ingredients only after complete dispersion is achieved.

Advantages: This core solution fundamentally prevents instantaneous contact between powder and large volumes of water.

It is simple to implement, ensures complete HPMC dissolution, and maximizes efficacy.

Solution 2:

If process constraints prevent altering the existing addition sequence, use this pre-dispersion method.

Steps:

- Reserve a portion of water during ingredient preparation. Mix this reserved water with hydroxypropyl methylcellulose.

- After complete dispersion, add the mixture to the product in liquid form.

Key Considerations:

- Water quantity is critical: The reserved water must be sufficient. Insufficient water will cause the mixture to agglomerate during pre-dispersion.

- Immediate action: If caking unexpectedly occurs during slurry preparation, immediately add a large amount of water and accelerate stirring. Do not wait. Once the agglomerates fully form, they become extremely difficult to dissolve.

III. Key Application Characteristics of HPMC

To apply HPMC flexibly, mastering its core properties is essential:

- Hydroxypropyl methylcellulose functions as a thickener only within pH 6-10 formulations; it is unsuitable for strong acid or alkali systems. Under strong acid (pH < 3) or strong alkali (pH > 10) conditions, its molecular chains degrade easily, causing significant viscosity loss or complete failure.

- HPMC’s onset time is influenced by water temperature and pH: higher temperatures accelerate onset, while lower temperatures slow it down. Acidic pH delays onset, whereas alkaline pH accelerates it.

- HPMC’s thickening effect does not necessarily correlate directly with its inherent viscosity. Consequently, different HPMC grades with identical viscosities and addition levels may exhibit significant variations in thickening performance within actual systems. Selecting a product grade validated through application testing is crucial.