Hydroxypropyl Methylcellulose (HPMC) in Personal Care

In daily applications, we have summarized five typical issues customers encounter when using Hydroxypropyl Methylcellulose (HPMC). Here is a technical analysis and provided solutions.

Issue 1: How to Control the Thickening Onset Time of Hydroxypropyl Methylcellulose?

Phenomenon Analysis: The thickening onset time of Hydroxypropyl Methylcellulose (HPMC) can vary between batches, which is closely related to the production process. Some customers wish to shorten this time to improve production efficiency.

Mechanism: The dissolution of Hydroxypropyl Methylcellulose (HPMC) follows a “swelling-dissolution” pattern, and its dissolution rate is significantly affected by ambient temperature and pH value.

Solutions:

1.Add a small amount of alkaline substance (e.g., soda ash, sodium bicarbonate) to raise the system’s pH and accelerate the unfolding of molecular chains.

2.Use warm water for dissolution to increase the rate of molecular thermal motion.

Our company can provide customized Hydroxypropyl Methylcellulose (HPMC) products with specific onset times according to customer requirements.

Issue 2: Why Does Hydroxypropyl Methylcellulose with the Same Viscosity Grade Have Different Thickening Effects?

Mechanism Analysis: The nominal viscosity of Hydroxypropyl Methylcellulose (HPMC) reflects only one dimension of its rheological properties. The actual thickening efficiency is also influenced by structural factors such as molecular weight distribution, and the type and distribution of substituents.

Recommended Solution: For superior thickening performance, we recommend our D905 product. This grade is specially optimized through a unique process to significantly enhance thickening efficiency.

Issue 3: How Does Ambient Temperature Affect the Product?

Mechanism Explanation: Hydroxypropyl Methylcellulose (HPMC) solutions are thermosensitive. Their viscosity decreases as the temperature increases, due to changes in molecular chain conformation and the strength of hydrogen bonding.

Observed Phenomenon: Higher product consistency in winter and lower consistency in summer is an inherent characteristic of the material.

Issue 4: Transparency Comparison: HEC, CMC vs. Hydroxypropyl Methylcellulose (HPMC)

Performance Characteristics:

Hydroxyethyl Cellulose(HEC) and Sodium Carboxymethylcellulose (CMC) generally offer higher transparency but have specific requirements for the formulation system.

Hydroxypropyl Methylcellulose (HPMC) has a wider range of applications and offers better cost-effectiveness.

Recommended Solution: For applications with special transparency requirements, we recommend our high-clarity grade D906.

Issue 5: Can Hydroxypropyl Methylcellulose (HPMC) Be Used in Shampoo, Conditioner, Body Wash, Hand Soap, and Cosmetics, Beyond Detergents?

Answer: Firstly, the answer is definitely yes. Personal care grade Hydroxypropyl Methylcellulose (HPMC) can be applied in these products.

Shampoo and Conditioner Application: Personal care grade Hydroxypropyl Methylcellulose (HPMC) not only acts as a thickener but also enhances the setting capability of shampoos and conditioners, thereby improving hair manageability.

Body Wash and Hand Soap Application: Hydroxypropyl Methylcellulose (HPMC) can form a protective layer on the surface. This not only improves the efficiency of the cleaning product but also provides lasting protection against stains and damage.

Cosmetics Application: Hydroxypropyl Methylcellulose (HPMC) stabilizes, thickens, and moisturizes the product. It can also optimize fragrance retention, ensuring the scent lasts longer.

Important Note: Although Hydroxypropyl Methylcellulose (HPMC) has a wide range of applications, it is not suitable for all formulations. Customers need to select the most appropriate product based on their specific formula.

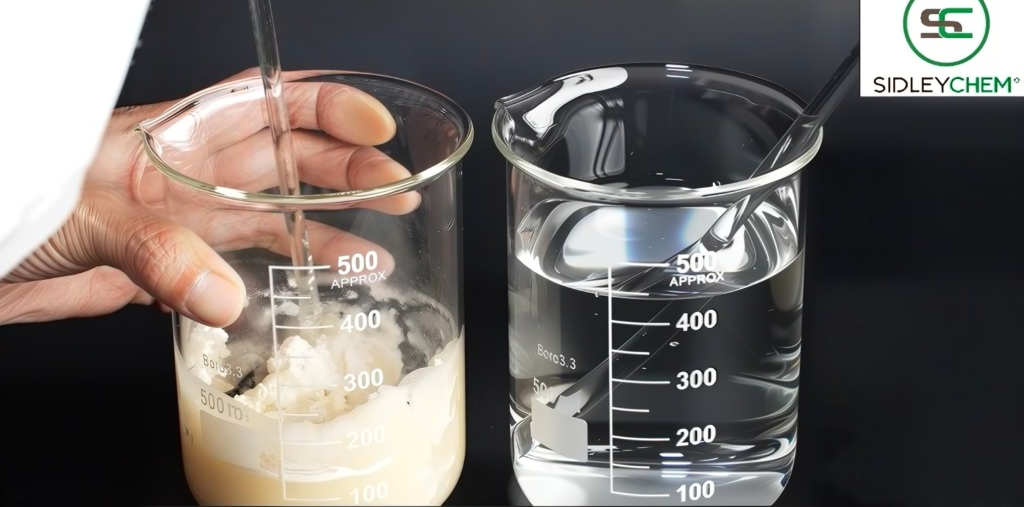

This video is about Our product HPMC D906 rapid sticking.