sand clay influence tile adhesive

With the advancement of the times, dry powder construction products have gained widespread popularity. These products offer quick and convenient use—simply add water, mix, and apply. Dry powder tile adhesives stand as the most representative product in this category.

Professional manufacturing plants commonly use sand as aggregate when producing tile adhesives. Construction dry powders impose specific requirements on the moisture content and clay content of the sand used. This article briefly discusses the impact of clay-containing sand (20% clay content) on tile adhesive performance.

1. Impact on Tile Adhesive Wetting Properties

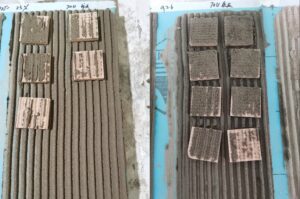

As shown below, the difference is significant: tile adhesive with clay-containing sand exhibits wetting times around 5 minutes, while adhesive without clay-containing sand takes approximately 25 minutes.

2. Impact on Open Time of Tile Adhesive

2.1.1 As shown below: Cured under laboratory conditions for 14 days

2.1.2

| silt | Sand | |||||

| Serial Number

|

Test Number

|

10min/MPa | 20min/MPa | 10min/MPa | 20min/MPa | Note

|

| 1 | A | 0.69 | 0.04 | 1.86 | 1.6 | |

| 2 | B | 1.14 | 0.84 | 1.29 | 0.64 | |

| 3 | C | 0.90 | 0.32 | 1.77 | 0.79 | |

| 4 | D | 1.07 | 1.01 | 0.72 | 0.5 | |

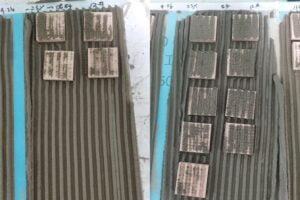

2.2 As shown below: Cured under laboratory conditions for 28 days

2.2.2

| silt | Sand | |||||

| Serial Number

|

Test Number

|

10min/MPa | 20min/MPa | 10min/MPa | 20min/MPa | Note

|

| 1 | A | 0.4 | 0.14 | 1.46 | 1.36 | |

| 2 | B | 1.41 | 0.57 | 1.82 | 1.49 | |

| 3 | C | 0.78 | 0.29 | 0.90 | 0.90 | |

| 4 | D | 1.23 | 0.43 | 1.01 | 0.88 | |

The figures and table data reveal that the open time for tile adhesive with clay-sand is 10 minutes, while that for tile adhesive without clay-sand exceeds 20 minutes.

3.summary

-Significantly Reduced Wetting Performance

The inclusion of sand significantly shortens the wetting time of the adhesive from 25 minutes to 5 minutes, severely impacting the material’s spreadability and initial adhesion on tile surfaces.

-Substantially Reduced Open Time

Experimental data indicates that the open time for the sand-containing system decreases from over 20 minutes to approximately 10 minutes, severely limiting construction flexibility.Bond strength is markedly reduced.