Hydroxyethyl Cellulose (HEC) Application

Question 1: What are the applications of Hydroxyethyl Cellulose (HEC)?

Hydroxyethyl Cellulose (HEC) is a non-ionic, water-soluble polymer possessing functionalities such as thickening, suspending, binding, emulsifying, film-forming, stabilizing, dispersing, and water retention. It can serve as a surfactant, colloid protector, and dispersing agent, finding widespread applications in the following industries:

Coatings, textiles, dyeing, papermaking, cosmetics, pharmaceuticals, pesticides, etc. It is also used in the petroleum industry and mineral processing.

Note: Hydroxyethyl Cellulose (HEC) is available in different grades such as industrial grade, personal care grade, and pharmaceutical grade. Please select the appropriate specification based on the intended use.

Question 2: What are the advantages of Personal Care Grade HEC in applications?

In shampoos, hair sprays, hair care products, and cosmetics, personal care grade Hydroxyethyl Cellulose (HEC) can act as a film-forming agent, adhesive, thickener, stabilizer, and dispersant. In detergents, it functions as an anti-soil redeposition agent. Its use significantly enhances the smoothness and silky gloss of fabrics after washing.

Question 3: What is the correct method for adding Hydroxyethyl Cellulose (HEC)?

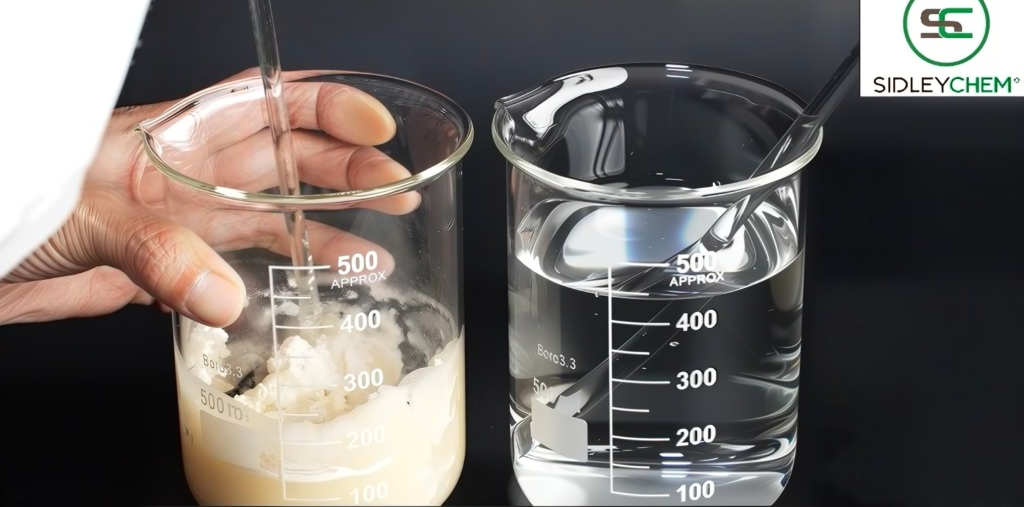

Hydroxyethyl Cellulose (HEC) is soluble in both hot and cold water. The correct addition method is as follows:

It is recommended to slowly sift the powder into the water while stirring under agitation, ensuring it is fully dispersed in water before incorporating it into the product system.

A sufficient amount of water should be used; otherwise, clumping may occur easily.

Question 4: In coating applications, does the use of HEC potentially lead to bubble formation?

Bubble formation is primarily due to the continuous stirring during the dissolution process of Hydroxyethyl Cellulose (HEC), which introduces air.

Common solutions include:

Natural Defoaming: Allowing the product to stand enables bubbles to gradually escape. This method is suitable when time is ample but is less efficient for production.

Adding Defoamers: This can quickly eliminate bubbles and is suitable for continuous production. Although it increases cost, it saves time.

Users can select the appropriate defoaming method based on their actual needs.

Question 5: In coating applications, how to address the enzyme resistance of HEC?

To improve the biodegradation resistance of Hydroxyethyl Cellulose (HEC) formulations, it is recommended to add corresponding preservatives and biocides to the system. The specific selection should consider the application scenario:

Exterior Wall Coatings: Choose preservatives that inhibit the growth of mold and algae.

Interior Wall Coatings: It is advisable to select types that offer mildew and moisture resistance, good weatherability, and high safety.