Carboxymethyl Starch

Carboxymethyl starch is a type of modified starch, also known as carboxymethyl starch-Na. Used in printing and dyeing, carboxymethyl starch serves as a carrier paste for dyes and printing auxiliaries(Carboxymethyl Starch Printing thickener), offering excellent compatibility and stability. Dyeing pastes formulated with carboxymethyl starch also exhibit excellent permeability. This is particularly advantageous for deep-penetrating fabric printing, enabling rapid pattern reproduction according to the stencil design while significantly enhancing print vibrancy. Additionally, carboxymethyl starch dissolves readily in cold water, ensuring convenient handling.

The printing performance of carboxymethyl starch primarily depends on its purity and degree of substitution (etherification). Low etherification or uneven etherification results in poor acid, alkali, and salt resistance, as well as low water solubility. During preparation of the printing paste, unreacted primary hydroxyl groups react with reactive dyes, causing deposits on the fabric surface that result in a stiff handfeel. Insoluble suspended particles in the paste may also lead to printing defects. Increasing the etherification degree of carboxymethyl starch to above 1.0 significantly enhances the chemical stability of the paste, improving its flow and penetration properties, thereby enhancing printing performance.

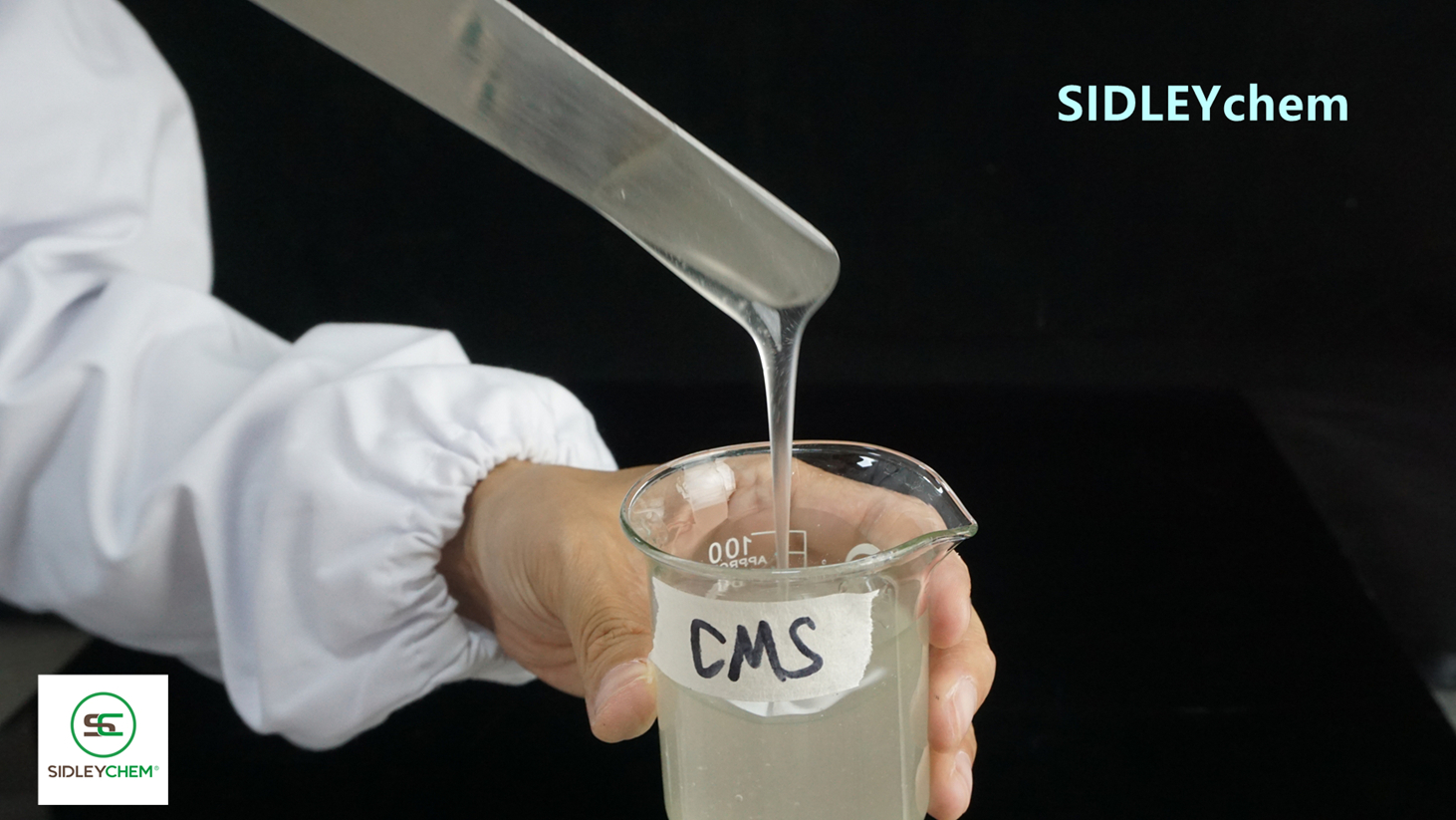

Carboxymethyl starch(CMS) exhibits a low paste yield, representing a typical high-solid-content, low-viscosity paste with an original paste concentration generally around 8%, leading to paste wastage. As a classic non-Newtonian fluid, carboxymethyl starch possesses significant structural viscosity and a highly viscous appearance, with a PVI value of approximately 0.4. However, this viscosity stems not from intermolecular forces but from the difficulty of molecular chain clusters migrating in water.

Carboxymethyl starch lacks the viscoelasticity of sodium alginate, resulting in poor water retention where water molecules between molecular chains remain largely free. The most significant characteristic of printing with this paste is severe bleeding. Attempting to prevent bleeding by increasing paste concentration leads to excessive paste residue on the fabric, compromising hand feel and causing mottling.

Methods to improve carboxymethyl starch printing performance:

(1) Use products with high viscosity, high substitution degree, and high purity(Carboxymethyl Starch Printing thickener)

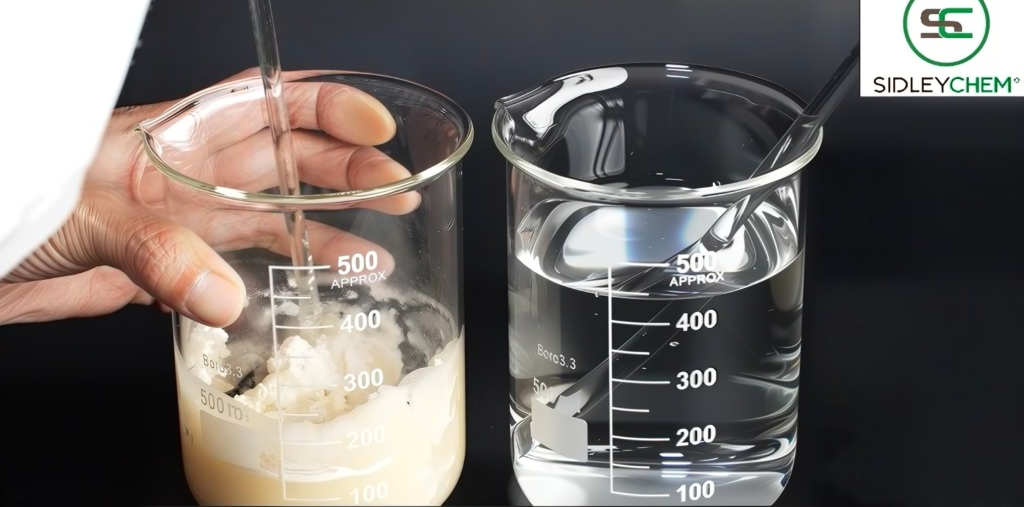

(2) Blend carboxymethyl starch with other binders for printing. Using sodium alginate blended with carboxymethyl starch for cotton fabric printing yields favorable results. Compared to pure carboxymethyl starch, the blended mixture exhibits improved water retention and drag properties. It also achieves higher color yield post-printing while reducing binder costs.