The Hydroxypropyl Methylcellulose D Series is a specially customised, high-purity HPMC. Selected from premium raw materials and manufactured through bespoke production processes to meet the thickening and purity requirements of the cosmetics and personal care sector, it exhibits the following characteristics:

- High molecular weight, concentrated and uniformly substituted, delivering exceptional thickening efficiency;

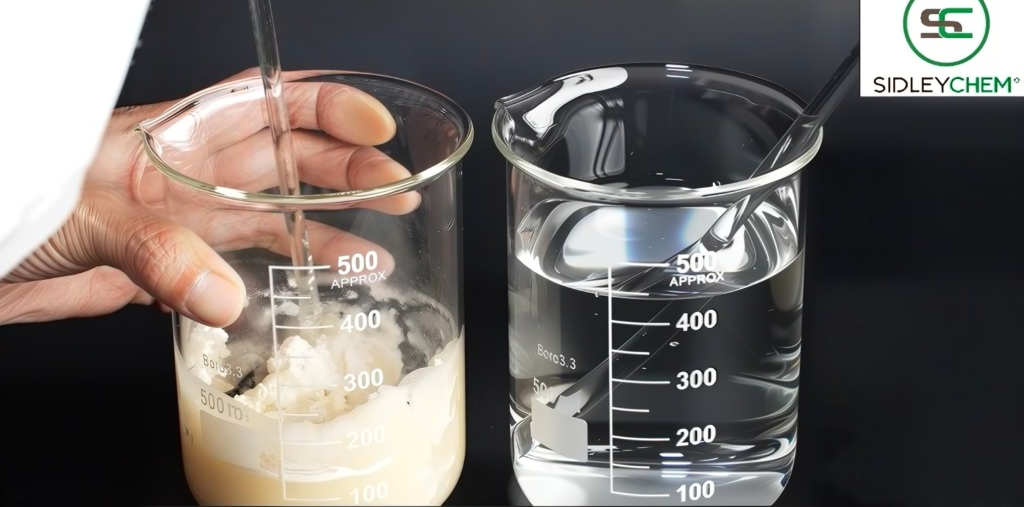

- High purity with low ash content, offering outstanding transparency;

- Uniform surface treatment and rational particle size distribution, ensuring rapid dispersion.