hand sanitizer formulation

How to Choose the Right Hand Sanitizer?

Hand sanitizers can be broadly categorized into three types: Regular, Antibacterial/Specialty, and Waterless (Hand Rub). Understanding their differences is key to selecting the right product for your needs.

-

Regular Hand Soap/Liquid: This is the common product found in supermarkets, functioning primarily as a cleaner similar to liquid soap for daily handwashing to remove dirt and grime.

-

Antibacterial/Specialty Hand Wash: Designed for more demanding environments like hospitals, supermarkets, and high-traffic public areas. In addition to surfactants, they contain antimicrobial agents. According to standards, products labeled “antibacterial” must achieve a >90% bactericidal rate, while “bacteriostatic” products require a >50% inhibition rate.

-

Waterless Hand Sanitizer (Hand Rub): A convenient option containing alcohol (ethanol/isopropanol) and skin-conditioning agents. It requires no water; simply apply and rub hands together for 1-3 minutes. Ideal for travel or outdoor use, offering effective disinfection when alcohol content is around 60-80%.

2. What’s Inside a Hand Sanitizer Formula?

Hand sanitizer formulations are engineered blends of components serving specific functions. Here’s a breakdown of common ingredients:

2.1 Core Components of Regular Hand Soap:

-

Surfactants: For cleansing and foaming. Typically, an anionic surfactant like Sodium Laureth Sulfate (AES) or Sodium Lauryl Sulfate (SLS/K12) serves as the primary cleaner, often combined with a milder amphoteric surfactant like Cocamidopropyl Betaine (CAB) or a non-ionic like Cocamide DEA (6501) to reduce skin irritation.

-

Skin Conditioners & Humectants: Ingredients like Glycerin, Propylene Glycol, or Sorbitol (typically 1-3%) are added to counteract dryness, retain moisture, and leave a protective film on the skin.

-

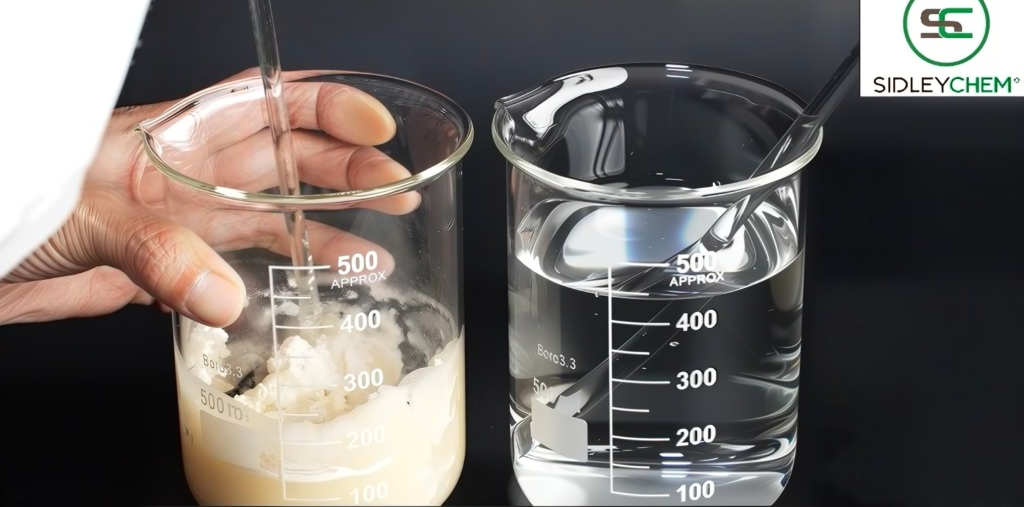

Thickeners/Rheology Modifiers:

Used to achieve the desired viscosity and product feel. Hydroxypropyl Methylcellulose (HPMC), such as our product D906, is an excellent choice for effective thickening and high clarity, enhancing user experience.

Used to achieve the desired viscosity and product feel. Hydroxypropyl Methylcellulose (HPMC), such as our product D906, is an excellent choice for effective thickening and high clarity, enhancing user experience. -

Preservatives: Such as Sodium Benzoate, Parabens, or Isothiazolinones (e.g., Kathon CG), are essential to prevent microbial growth and ensure shelf-life stability.

-

2.2 Functional Formulation Variants:

-

Antibacterial Hand Wash: Incorporates Benzalkonium Chloride, Chloroxylenol (PCMX), etc., adhering strictly to local regulatory limits for antimicrobial agents.

-

Skin-Care Focused Hand Wash: Enriched with natural oils (Olive Oil, Jojoba Oil) or botanical extracts (Paeonol, Flavonoids) for anti-inflammatory and soothing properties, suitable for sensitive skin.

-

Eco-Friendly/Biodegradable Formulations: Utilize readily biodegradable surfactants like Alkyl Polyglucosides (APG) to minimize environmental impact.

-

Waterless Hand Sanitizer Formulations:

-

Alcohol-Based: Rely on Ethanol or Isopropanol (optimal efficacy at ~75% v/v) as the main antimicrobial, combined with humectants like glycerin to prevent dryness.

-

Alcohol-Free: May use alternative actives like Quaternary Ammonium Compounds (e.g., Benzalkonium Chloride/Bromide), Chlorhexidine, Hydrogen Peroxide, or Hypochlorous Acid. Some variants feature plant extracts (Aloe Vera, Calendula), though their antimicrobial efficacy is generally lower than chemical actives.

-

-