Starch ether gypsum thickening

Starch ether is a type of etherified starch produced through chemical reactions using raw materials such as potato, corn, and tapioca. It is widely used in building dry-mix mortars. Its primary functions include thickening, anti-sag, reduction of application viscosity, improvement of workability, and extension of open time. This article explores the thickening performance of starch ether in building gypsum (β-hemihydrate) based on practical test data.

I. Test Data Overview

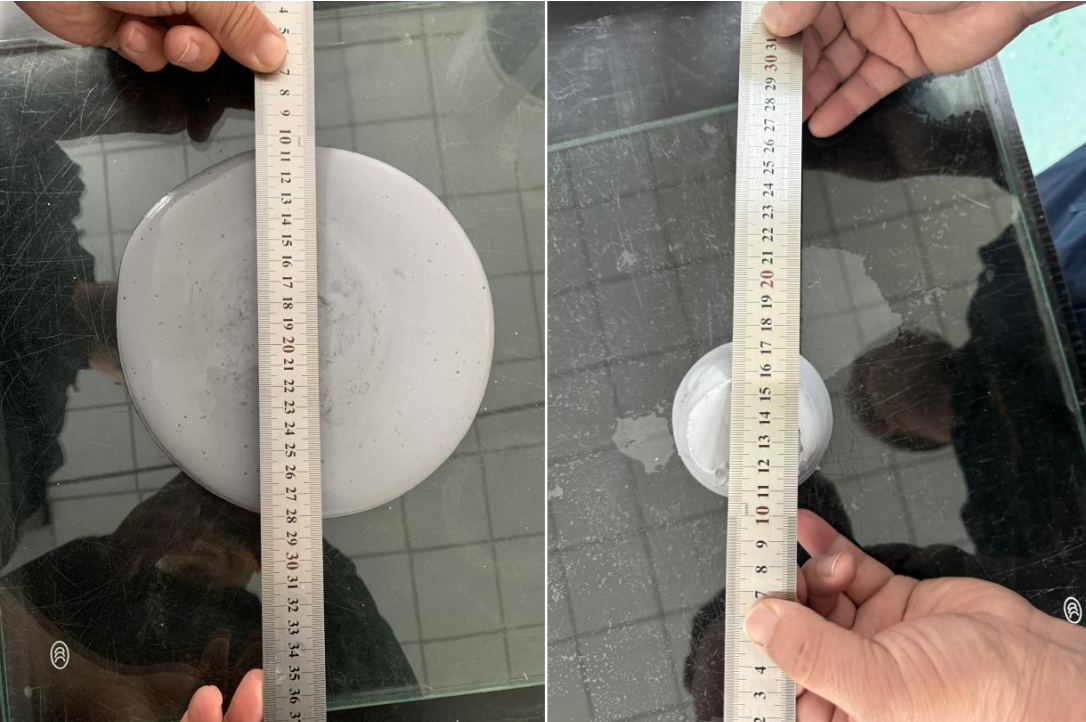

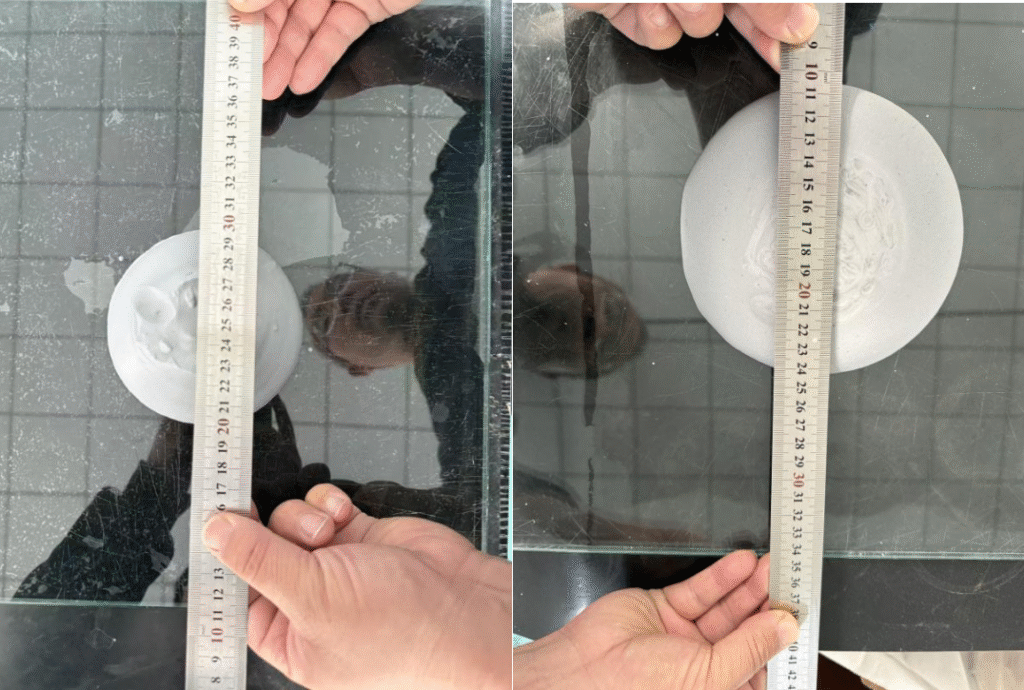

The following table presents test results of starch ether from different origins and types in building gypsum, with a dosage of 0.3‰ and a water addition of 65%:

| Test No. | Origin | Dosage / ‰ | Water Addition / % | Consistency / mm | Remarks | |

| 1# | / | 0 | 65 | 182 | ||

| 2# | China | 0.3 | 65 | 165 | ||

| 3# | China | 0.3 | 65 | 97 | 302 | |

| 4# | China | 0.3 | 65 | 150 | 501 | |

| 5# | China | 0.3 | 65 | 120 | 801 | |

| 6# | Netherlands | 0.3 | 65 | 83 | ||

| 7# | Netherlands | 0.3 | 65 | 120 | ||

| 8# | Austria | 0.3 | 65 | 135 | ||

| 9# | Germany | 0.3 | 65 | 133 | ||

| 10# | Germany | 0.3 | 65 | 80 | ||

| 11# | Germany | 0.3 | 65 | 160 | ||

| 12# | Thailand | 0.3 | 65 | 180 | ||

Note: 302, 501, and 801 are our company’s products.

II. Results Analysis

From the test data, it can be observed:

Starch ethers of European origin show significant thickening effects, with some samples even exhibiting extreme thickening (e.g., Test Nos. 6# and 10# have consistency values lower than the blank group).

Conventional starch ethers provide moderate thickening effects. However, through formulation optimization, our products 302, 501, and 801 demonstrate excellent performance in specific applications:

Type 302 is suitable for tile adhesives, with a consistency of 97 mm.

Type 501 is suitable for cement-based putty products, with a consistency of 150 mm.

Type 801 is specially designed for gypsum products, with a consistency of 120 mm.

III. Conclusion

The thickening effect of starch ether is significantly influenced by raw materials and production processes. Selecting the appropriate starch ether product can effectively enhance the construction performance and final quality of building gypsum. Through targeted research and development, our starch ethers can achieve ideal results in specific applications.

For further information on starch ether products suitable for different scenarios (such as 302, 501, 801), please feel free to contact us. We offer professional technical support and solutions.