Starch Ether in Portland Cement

I. Definition and Functional Overview of Starch Ether

- Starch ether is a type of etherified starch produced through chemical reactions using raw materials such as potato, corn, and tapioca. In building dry-mix mortars, starch ether primarily functions as a thickener, effectively enhancing the anti-sag properties of mortar, reducing application viscosity, improving workability, and extending open time.

II. Research Objective and Experimental Data

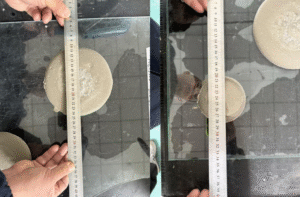

This article briefly presents the thickening performance of starch ether in Portland cement systems. The experimental data are shown in the following table:

| Test No. | Origin | Dosage / ‰ | Water Addition / % | Consistency / mm | Remarks |

| 1# | / | 0 | 50 | 150 | |

| 2# | China | 0.3 | 50 | 121 | |

| 3# | China | 0.3 | 50 | 117 | SE-302 |

| 4# | China | 0.3 | 50 | 108 | SE-501 |

| 5# | China | 0.3 | 50 | 85 | SE-801 |

| 6# | Netherlands | 0.3 | 50 | 90 | |

| 7# | Netherlands | 0.3 | 50 | 120 | |

| 8# | Austria | 0.3 | 50 | 103 | |

| 9# | Germany | 0.3 | 50 | 96 | |

| 10# | Germany | 0.3 | 50 | 89 | |

| 11# | Germany | 0.3 | 50 | 120 |

Note: 302, 501, and 801 are our company’s products.

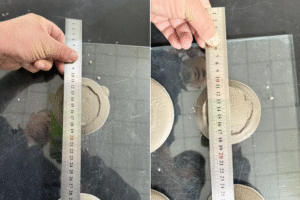

III. Experimental Results Analysis

Starch ethers of European origin generally demonstrate good thickening effects, with some samples exhibiting significant thickening performance;

Conventional starch ethers show slightly lower thickening effectiveness compared to European products; Our manufactured starch ether SE-302 is suitable for tile adhesives, SE-501 for cement-based putty products, and SE-801 for gypsum products.

We welcome customers with relevant needs to inquire about cooperation. We will provide professional technical support and product services.