Improve mortar workability

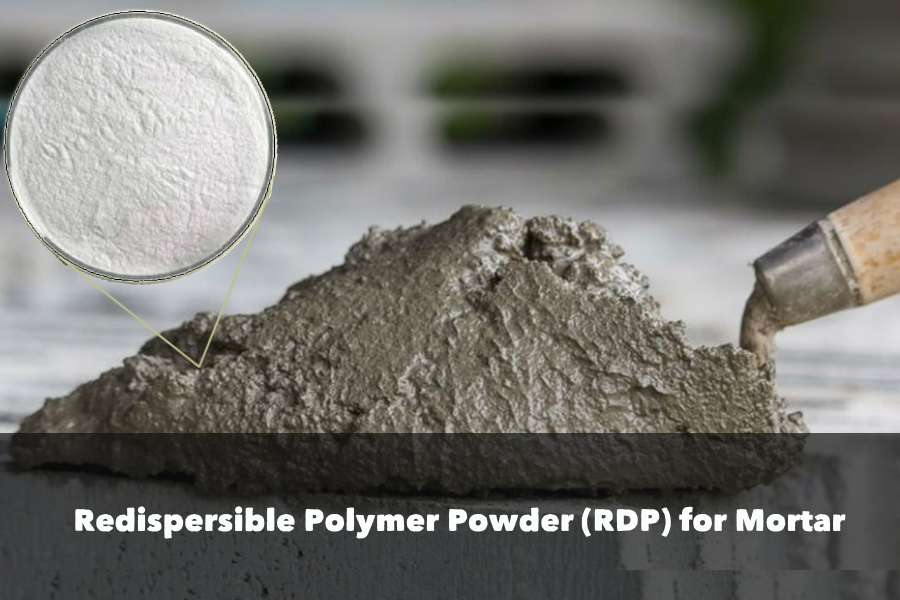

In construction, traditional mortars often face issues such as short open time, difficult application, and insufficient adhesion. Redispersible Polymer Powder (RPP), as a functional polymer additive, can effectively address these pain points. This article analyzes its mechanism of action and practical application effects.

I. What is Redispersible Polymer Powder?

Redispersible Polymer Powder is a high-molecular-weight polymer powder produced via spray drying. It can redisperse in water to form an emulsion, retaining its adhesive properties, making it suitable for use in dry-mix mortars. Its addition results in “polymer-modified mortar” with significantly enhanced performance.

II. Common Problems with Traditional Mortar

Conventional mortar is typically made by mixing cement, gypsum, or lime with fine sand or stone chips and a small amount of additives. Such mortars often encounter the following problems during production and application:

1.Short open time

2.Difficult application: sticky, hard to trowel and spread

3.Loose state, prone to spillage, poor stickiness

4.Prone to sagging

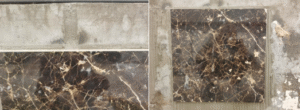

5.Susceptible to cracking, hollowing, and detachment

III. Mechanism of Action and Performance Enhancement

After adding Redispersible Polymer Powder to the mortar, it redisperses in the hydration system and forms a continuous polymer film. This film structure interweaves with cement hydration products, forming an organic-inorganic composite three-dimensional network, fundamentally improving various properties of the mortar:

1.Extended Open Time: The polymer film formation slows down water evaporation and loss.

2.Improved Workability: Enhances plasticity and smoothness for easier application.

3.Excellent Adhesion: Improves stickiness to various substrates.

4.Anti-Sagging: Increases thixotropy, suitable for vertical application.

5.Enhanced Adhesion Strength: (to organic materials like EPS insulation boards).

6.Improved Cohesive Strength: (e.g., waterproof strength in tile adhesive, tensile strength in insulation rendering mortar).

7.Increased Flexibility: (e.g., in rendering mortar for external insulation systems).

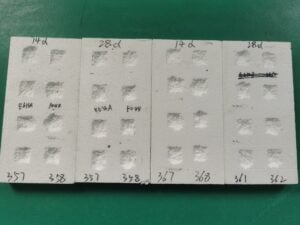

IV. SidleyChem Product System: Professional Solutions for Different Scenarios

By rationally selecting Redispersible Polymer Powder, mortar construction challenges can be systematically solved. SidleyChem provides a full range of Redispersible Polymer Powder products to meet various engineering needs. Our portfolio includes Series 6 (rigid), Series 7 (semi-flexible/semi-rigid), Series 8 (flexible), and Series 9 (specialty) products for selection. We provide comprehensive products and technical support to help improve project quality.