Coatings Thickener Usage Guide

Coatings thickeners are essential coating additives primarily used to regulate the rheological properties of coatings and improve application performance. Below, we provide a detailed overview of their specific functions and usage methods.

I. Main Functions of Coatings Thickeners

-

Adjust Coating Viscosity:Thickeners effectively increase coating viscosity by forming a three-dimensional network structure. This not only makes the coating easier to apply but also ensures it adheres to the substrate at an appropriate thickness.

-

Enhance Adhesion:By increasing coating viscosity, thickeners prolong the dwell time of the coating on vertical surfaces, allowing full contact with the substrate, thereby improving adhesion.

-

Improve Coverage Performance:Optimal viscosity prevents rapid pigment settling, ensuring uniform pigment distribution and enhancing the coating’s hiding power, making it easier to cover surface defects on the substrate.

II. Correct Usage Methods

-

Addition Steps

-

Thoroughly stir the coating first

-

Slowly add the thickener while maintaining stirring

-

Continue stirring until fully homogeneous

-

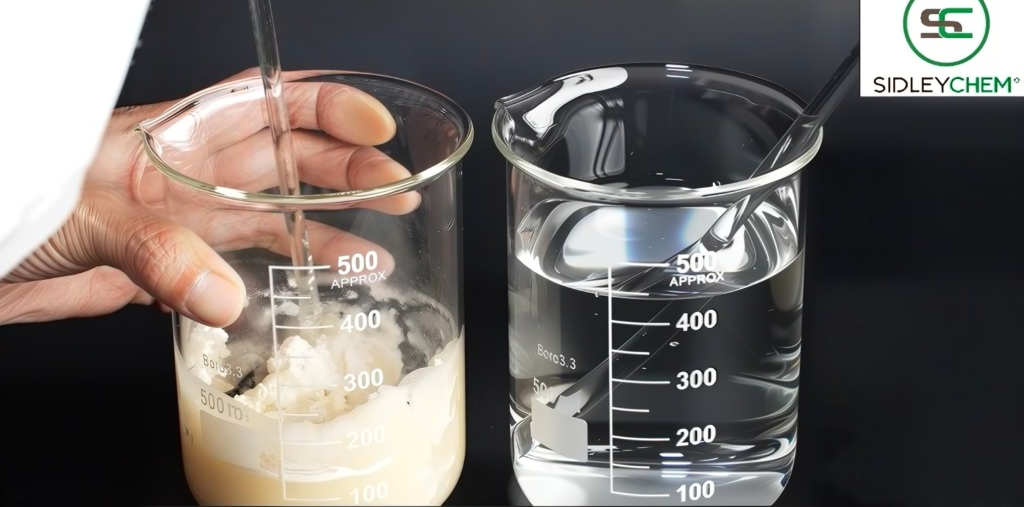

Key Usage Points

-

It is recommended to add in batches for better viscosity control

-

If clumping occurs during addition, extend the stirring time

-

Adjust the dosage as needed to achieve the desired viscosity

III. Important Considerations

-

Maintain continuous stirring during thickener addition to ensure uniform dispersion

-

If viscosity is too high, add a small amount of water for adjustment

-

Conduct small-scale tests prior to full application

-

Pay attention to compatibility with different coating systems