ETIRS adhesive powder additives

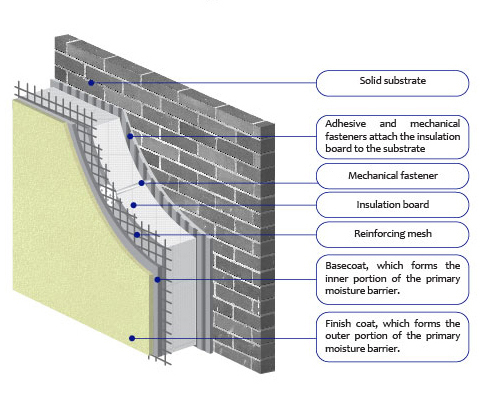

The Expandable Polystyrene (EPS) Thermal Insulation Rendering System (ETIRS), as a widely used site-applied insulation system, derives its core performance from the quality of the dry-mixed bonding powder. This powder, when mixed on-site with recycled EPS beads, forms an insulating plaster that combines excellent thermal insulation, mechanical strength, and workability.

I. Core Formulation and Functional Analysis of Bonding Powder

A typical formulation system for high-performance bonding powder is:

Cement + Supplementary Cementitious Materials + Fillers + Cellulose Ether + Modified Polyethylene Oxide (PEO) + Redispersible Polymer Powder (RDP) + Polyvinyl Alcohol (PVA) + Wood Fiber + Polypropylene Fiber.

Each component plays an indispensable role:

-

Cement, SCMs & Fillers: Form the strength foundation and skeleton of the system.

-

Cellulose Ether: Provides crucial water retention and thickening, ensuring plaster workability, preventing rapid water loss, and enhancing cohesion.

- Modified Polyethylene Oxide (PEO): Significantly improves plaster viscosity and rheology, enhancing anti-sag properties for easier, more uniform application.

-

Redispersible Polymer Powder (RDP) & Polyvinyl Alcohol (PVA): These two work synergistically to provide exceptional adhesive strength, flexibility, and film-forming properties. They are key to achieving high bond strength, crack resistance, and impact resistance in the plaster.

-

Wood Fiber & Polypropylene Fiber: Provide three-dimensional reinforcement and crack resistance. Wood fiber improves wet mortar anti-sag and application feel, while polypropylene fiber effectively inhibits plastic and drying shrinkage cracking, enhancing the toughness of the hardened material.

II. SidleyChem High-Performance Additive Solutions for Bonding Powder

Addressing the technical requirements of bonding powder formulations, SidleyChem offers proven specialized products:

-

Cellulose Ethers:

-

Hydroxyethyl Methyl Cellulose (HEMC): e.g., ME 36M10, offering high water retention and excellent application smoothness.

-

Hydroxypropyl Methyl Cellulose (HPMC): e.g., MP 36M10, providing good water retention, thickening performance, and cost-effectiveness.

-

-

Polymeric Bonding & Enhancing Components:

-

-

Redispersible Polymer Powder (RDP): Options include 7028 (Economy Grade), 66145/66155 (Standard/Enhanced Grade), etc., to meet different adhesive strength and flexibility demands.

-

Polyvinyl Alcohol (PVA): 2488 (High viscosity, high bond strength), 1788 (Fast-dissolving, high flexibility), used to further enhance plaster adhesion and cohesive strength.

-

-

Rheology Modifier:

-

Modified Polyethylene Oxide (PEO): GH 5596, specifically designed to improve the rheological properties of insulating plaster, effectively enhancing workability and anti-sag resistance.

-

-

Crack-Resistance Fibers:

-

Wood Fiber: W500 / G500, improves wet mortar workability and reduces early-stage cracking.

-

Polypropylene Fiber: PP 6mm / 12mm, provides long-term physical reinforcement, significantly improving the crack and impact resistance of the hardened plaster.

-