High Silt Content Issues

1.Impact of High Silt Content on Concrete Properties

1.1 Reduced Strength

Excessive clay content causes soil particles to coat sand surfaces, hindering cement-aggregate bonding and reducing interfacial strength between cement paste and aggregates. Simultaneously, soil increases concrete’s water demand, disrupting water-cement ratio and indirectly lowering compressive strength.

1.2 Deterioration of Workability

Workability: Soil absorbs water and expands, reducing effective water content and adsorbing superplasticizer molecules, resulting in poorer concrete flowability.

Slump Loss: Requires an additional 10–15% water content, yet accelerates slump loss.

1.3 Risk of Shrinkage and Cracking

The strong water absorption of clay components increases drying shrinkage in concrete, readily inducing cracks.

1.4 Reduced Durability

Water Permeability: High clay content increases concrete porosity, creating pathways for water penetration and reducing impermeability.

Freezing Resistance: Water in pores expands during freeze-thaw cycles ( ), causing internal structural failure.

Reinforcement Corrosion: Soil particles may form conductive pathways, accelerating electrochemical corrosion of reinforcing steel.

2.Systematic Solutions

2.1. Raw Material Control and Pre-Treatment

Screening and Washing to Reduce Silt Content: Wash sand and gravel or use vibrating screens to control silt content below 3% (recommended for C30 and higher concrete grades).

Substitute Materials: Utilize manufactured sand (stone powder content ≤10%) or desalinated sea sand (chloride ion content <0.03%) to reduce reliance on natural sand.

2.2. Dynamic Mix Proportion Adjustment

Cementitious Material Compensation: For every 1% increase in clay content, add an additional 5–8 kg/m³ of cement (ACI 211.1 recommendation).

Water-Binder Ratio Optimization: When clay content is high, reduce the water-binder ratio by 0.02–0.05 to prevent excessive adsorption of free water.

2.3. Construction Process Improvements

Segmented Batching: First add 70% water and aggregate for 30 seconds of pre-mixing, then incorporate cementitious materials and remaining water to minimize clay particle agglomeration.

Dynamic Monitoring: Test slump every 2 hours. When loss exceeds 30%, immediately add 0.1–0.2% additional water-reducing agent.

2.4 Admixture Optimization Techniques

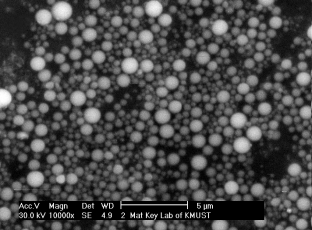

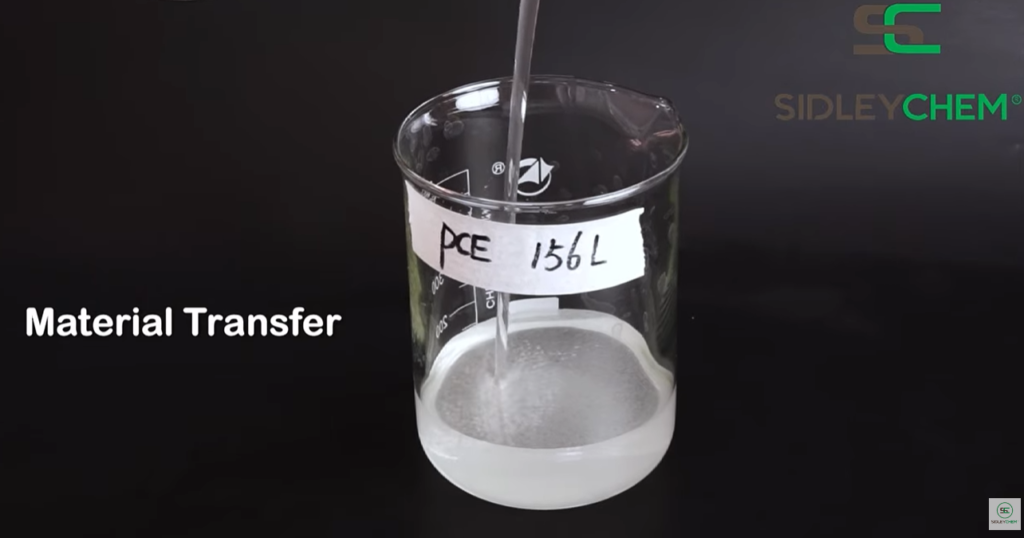

Compound Slow-Release Polycarboxylic Superplasticizer: Employ a “polycarboxylic + slow-release slump-retaining component” (e.g., hydroxycarboxylate) to prolong dispersion duration. For example, by rationally blending our polycarboxylic superplasticizers PCE156L + PCE155L + PCE157L, adding high-quality retarders SG100 or TCD98 and sodium metabisulfite, and supplementing with premium air-entraining agent Finish200, slump can be maintained without loss for 2-3 hours.