ETICS base coat mortar formulation

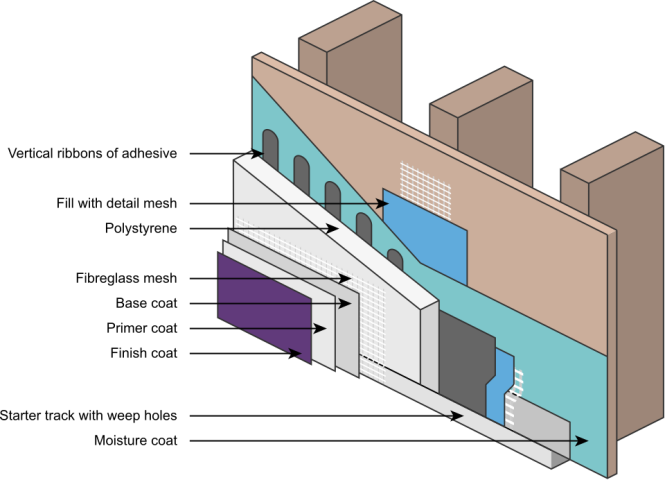

Within a complete External Thermal Insulation Composite System (ETICS, often referred to as EIFS), the base coat mortar (or reinforcing coat mortar), applied over the insulation layer and beneath the finish layer, is the core component ensuring the system’s long-term durability, impact resistance, and safety. It completely encapsulates the insulation boards, forming a robust protective shell, and crucially functions to withstand environmental stresses, distribute deformation stresses, and provide a high-quality substrate for the final finish.

I. Core Formulation & Functional Analysis

The foundation of a high-quality base coat mortar can be summarized as:

Cement + Graded Silica Sand + Filler + Cellulose Ether + Redispersible Polymer Powder (RDP) + Hydrophobic Agent + Wood Fiber + Polypropylene Fiber

These components work synergistically to impart the following key properties to the mortar:

Cement, Sand & Filler: Form the strength skeleton of the mortar, providing fundamental mechanical properties.

Cellulose Ether: Its core function is water retention and thickening, ensuring good workability, extending open time, and promoting complete cement hydration.

Redispersible Polymer Powder (RDP): Its core function is to enhance adhesion and flexibility. This is key for the mortar to achieve high impact resistance, crack resistance, and strong bond to the substrate.

Hydrophobic Agent: Its core function is to reduce water absorption, significantly improving the mortar’s water resistance and freeze-thaw durability to ensure long-term performance.

Wood Fiber & Polypropylene Fiber: Their core function is three-dimensional crack resistance and reinforcement. Wood fiber improves anti-sag during application and reduces plastic shrinkage cracking. Polypropylene fiber provides micro-reinforcement in the hardened mortar, effectively enhancing impact resistance and resistance to drying shrinkage cracks.

II. SidleyChem Targeted Product Solutions

To precisely achieve the above performance characteristics, SidleyChem offers a comprehensive portfolio of globally proven products:

Cellulose Ethers: HEMC (e.g., ME 34N01/02) and HPMC (e.g., MP 34N01/02) series to meet different water retention and viscosity requirements.

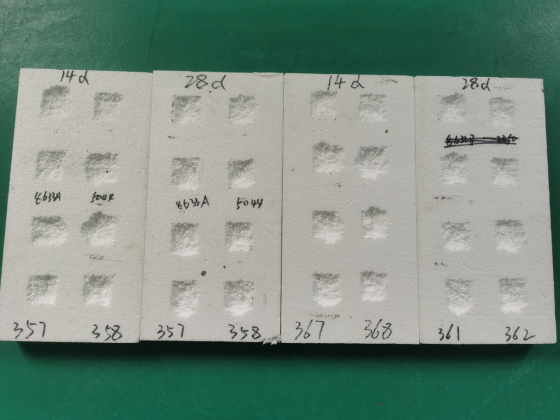

Redispersible Polymer Powder (RDP): A full range from Economy Grade (RDP 8012/8013), Standard Grade (RDP 7053/7033) to High-Performance/Toughness Grade (RDP 86353/86253) to match varying flexibility and strength demands.

Hydrophobic Agents: WS 80 / WS 90, highly efficient silicone-based products providing lasting water repellency protection for the system.

Fibers: Wood Fiber (W500/G500) and Polypropylene Fiber (PP 3mm/6mm), offering a comprehensive crack resistance solution throughout the mortar’s application and hardening process.

III. Conclusion

By deeply understanding the function of each component in base coat mortar and scientifically selecting high-performance additives, a protective layer that meets stringent engineering requirements can be systematically constructed. SidleyChem is committed to supporting our customers with our comprehensive product line and expert technical assistance to develop stable, reliable, and durable ETICS solutions.