How to assess HPMC quality?

In practical applications, the following four simple and effective methods can be used to quickly judge the basic quality of Hydroxypropyl Methylcellulose.

1.Observe Appearance and Color

High-quality Hydroxypropyl Methylcellulose typically exhibits a natural, off-white color with uniform consistency. This reflects the purity of the raw materials and the stability of the production process. It is important to note that some products might use whitening agents to enhance visual appeal, which can adversely affect performance. It is recommended to focus on color uniformity rather than solely pursuing whiteness.

2. Check Powder Fineness

The fineness of the powder directly affects the dissolution rate of Hydroxypropyl Methylcellulose. Generally, products with higher fineness (e.g., 100 mesh compared to 80 mesh) dissolve faster and are less likely to form undissolved “fish eyes.” A preliminary assessment can be made by feel, while a more accurate method involves testing with a standard sieve.

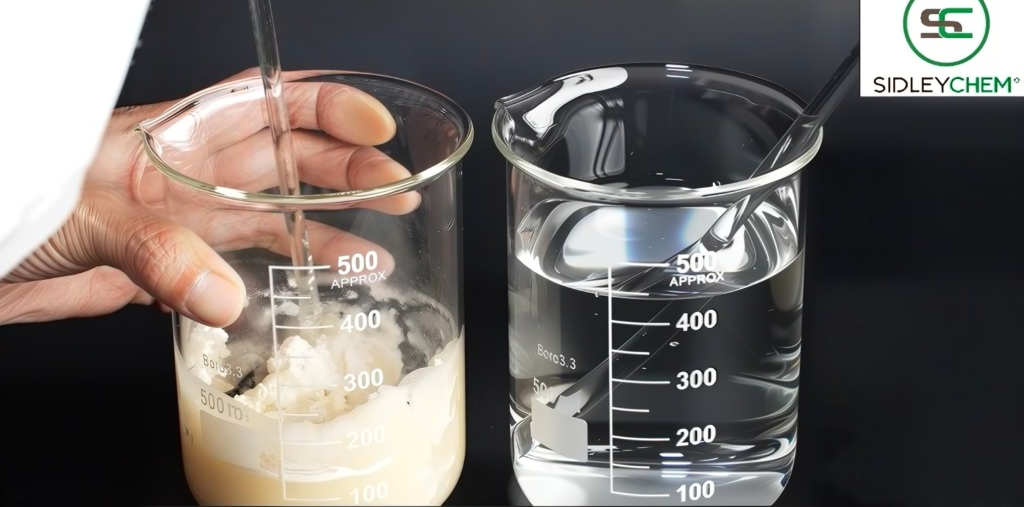

3. Test Solution Transparency

Dissolving Hydroxypropyl Methylcellulose and observing the transparency of the solution is an effective way to determine product purity. Higher transparency indicates lower insoluble content and signifies better quality. This characteristic is closely tied to the manufacturing process.

4. Compare Product Bulk Density

Bulk density is an important indicator for evaluating Hydroxypropyl Methylcellulose performance. A higher bulk density often suggests a higher hydroxypropoxyl content, which is directly related to the product’s water retention capability. A simple method for preliminary assessment is comparing the weight of equal sample volumes.