The advent of ready-mixed concrete has revolutionised traditional on-site concrete mixing methods, delivering numerous benefits. Firstly, the raw materials used in ready-mixed concrete are consistent, production processes are advanced, and fully computerised control ensures precise measurement alongside comprehensive quality inspection protocols. Consequently, concrete quality remains stable and reliable. Secondly, ready-mixed concrete enables the continuous and consistent supply of substantial volumes, accelerating construction pace and ensuring compliance with site-specific schedule requirements. Furthermore, its utilisation conserves resource expenditure, minimises site occupation and equipment hire costs, whilst preventing material wastage. Finally, the production method contributes to environmental improvement by reducing pollution associated with on-site mixing.

Ready Mixed Concrete

01Advantages of Ready-Mixed Concrete

02Primary Raw Materials for Concrete Plants

Concrete plants are vital equipment for producing concrete, utilising key materials such as aggregates, powdered materials, water, and admixtures.

1. Aggregates: Aggregates constitute one of concrete’s primary components, primarily serving as the structural framework. Common aggregates in batching plants include crushed stone, pebbles, and sand. These aggregates are blended in specific proportions to provide the strength and stability required for concrete.

2. Powdered Materials: Primarily referring to cement, this acts as the cementitious material in concrete, binding the aggregates together. Additionally, admixtures such as fly ash or ground granulated blast furnace slag may be incorporated as required to enhance concrete performance.

3. Water: An indispensable raw material in concrete production, water reacts with cement through hydration, causing the concrete to harden and gain strength. Clean freshwater is typically used as mixing water in batching plants.

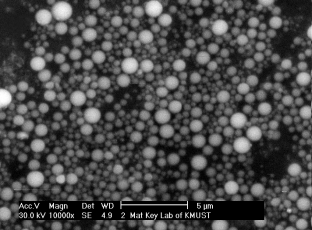

4. Admixtures: Admixtures are chemical additives employed to enhance concrete properties. Common types include water-reducing agents, retarders, and air-entraining agents. These admixtures improve concrete workability, delay setting time, and increase durability.

02Process Flow of Concrete Mixing Plant

The process flow of a Concrete Mixing Plant primarily comprises three stages: material storage and conveyance, batching and mixing, and finished product output and transportation.

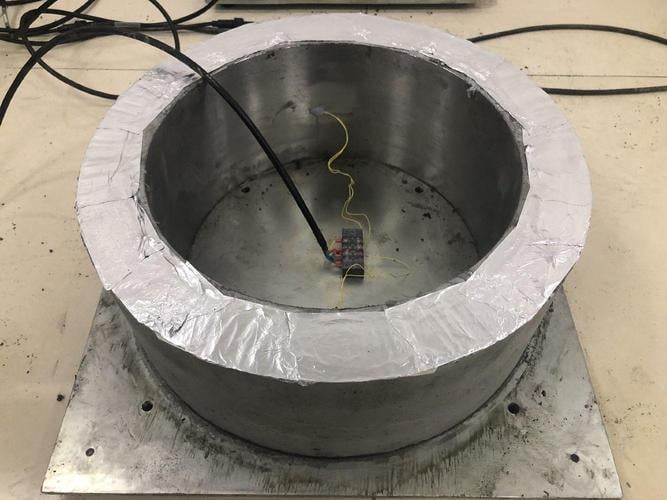

1. Material Storage and Conveyance: Firstly, various raw materials are conveyed to their respective storage silos. Aggregates are typically stored in open stockyards, whilst powdered materials, admixtures, and similar substances are kept in sealed containers. During production, all raw materials are precisely conveyed to the mixer via an automated control system.

2. Proportioning and Mixing: According to the specified concrete mix design, raw materials are conveyed into the mixer in predetermined proportions for blending. The mixer thoroughly agitates the components to ensure concrete homogeneity. Mixers are typically governed by computerised control systems to maintain consistent batch quality.

3. Product Output and Transportation: Upon completion of mixing, the finished concrete is transported via conveyor belts or pump trucks to construction sites or storage tanks for subsequent use. During transportation, measures must be taken to prevent undesirable phenomena such as segregation or bleeding, thereby maintaining consistent quality.

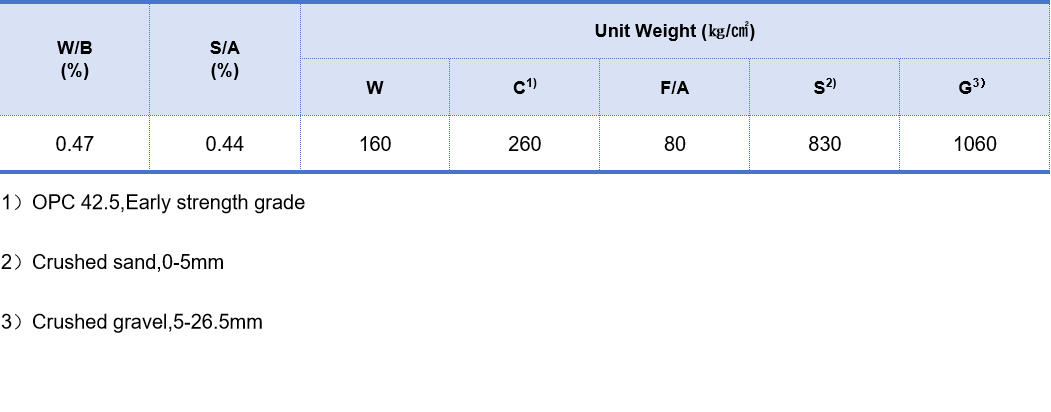

02C30 concrete mix design?

Specific constituent materials for C30 concrete.

1. Cement: P.042.5 grade, with a 28-day compressive strength of 47 MPa;

2. Sand: Medium sand from Zone II, with a fineness modulus of 2.7;

3. Crushed stone: Synthetic graded crushed stone of 5–25 mm, with a 5–10 mm to 10–25 mm ratio of 30%:70%;

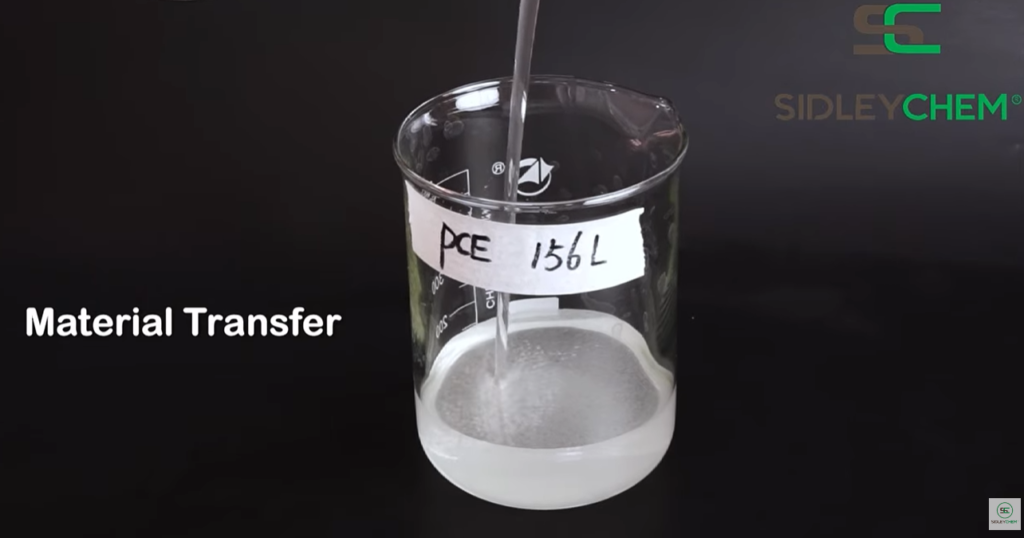

4. Admixture: Polycarboxylate superplasticiser(PCE 154L) added at 1.8% dosage, achieving 25% water reduction;

5. Fly ash: Grade F-II fly ash employed;

6. Granulated blast furnace slag powder: Grade S95 selected;

7. Mixing water: Drinking water used for mixing.

03Additives

SIDLEYchem boasts a technical team with over 20 years of production and synthesis expertise. Our production processes, derived from German technology, deliver outstanding performance Concrete Additives. We excel in concrete products while also serving as concrete solution providers, assisting clients in resolving diverse concrete challenges and supplying functional products.

Listening to client needs, we design the high performance additives for our customers!

04Oversea Base -Get Closer to you

We are actively expanding our manufacturing footprint with new production facilities dedicated to concrete admixtures and cellulose ethers. These strategically located plants are designed to uphold the highest quality standards while bringing us closer to our customers and business partners. Our commitment is clear: to deliver consistent excellence, faster response times, and localized support.

Stay tuned for exciting updates—because at SidleyChem, our strategy is simple but powerful: get closer to our customers and grow together.