Concrete surface defects

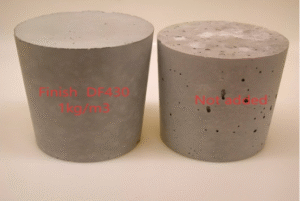

Since the widespread use of modern concrete, appearance defects such as bubbles, color differences, and pitting have been persistent issues, often termed an “incurable skin disease.” These problems consistently trouble industry professionals. Among them, surface bubbles not only affect aesthetics but also reduce structural density and durability.

I. Root Causes: Why Do Appearance Defects Occur in Concrete?

The formation of concrete appearance defects primarily stems from two levels:

1.Surface active agents in cement grinding aids, unreasonable aggregate gradation, and excessive water-cement ratio increase the potential for bubble formation. Simultaneously, issues during construction, such as insufficient or excessive vibration time, can lead to the entrapment or aggregation of bubbles.

2.Formwork release agents adsorbing bubbles and unstable slump (too low prone to segregation, too high making air release difficult) are also main causes of surface pitting.

II. Systematic Solutions: Full-Process Control from Raw Materials to Construction

- Raw Material Control

Cement: Select low-alkali cement without excessive grinding aids to minimize bubbles introduced by surfactants.

Aggregate: Optimize gradation, control sand ratio between 35% and 60%, and avoid using sand and aggregate with high clay content or a high flakiness index.

- Rational Mix Design and Production Quality Control

Keep the water-cement ratio ≤ 0.56. Appropriately increase cement content or use rheology modifiers to ensure concrete workability.

Excellent slump retention capability ensures construction slump is controlled between 120-180mm, balancing fluidity and air release requirements.

- Construction Process Optimization

Vibration: Use high-frequency vibrators for staged vibration, applying a “rapid insertion, slow withdrawal” technique. Maintain reasonable spacing to avoid over-vibration and missed spots.

Formwork: Treat formwork scientifically and apply a high-quality release agent evenly (avoid using waste oil).

III. Admixture Technology: Key Measures to Enhance Appearance Quality

The use of chemical admixtures to control concrete quality and improve appearance is increasingly being accepted and promoted. Here is a brief introduction to several types of admixture technical measures:

1.Use defoaming-type water reducers, which involves compounding defoamers into the admixture to eliminate unstable bubbles introduced by the water reducer itself.

1.Use defoaming-type water reducers, which involves compounding defoamers into the admixture to eliminate unstable bubbles introduced by the water reducer itself.

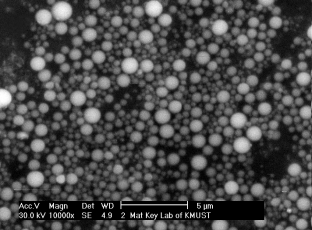

2.Use high-quality air-entraining agents that produce stable, tiny air bubbles (<20μm), improving bubble uniformity and preventing the aggregation of large bubbles.

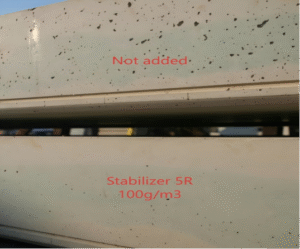

3.Use functional assistant viscosity modifying agents (VMAs) to improve paste cohesiveness and reduce bubble concentration caused by segregation during vibration.

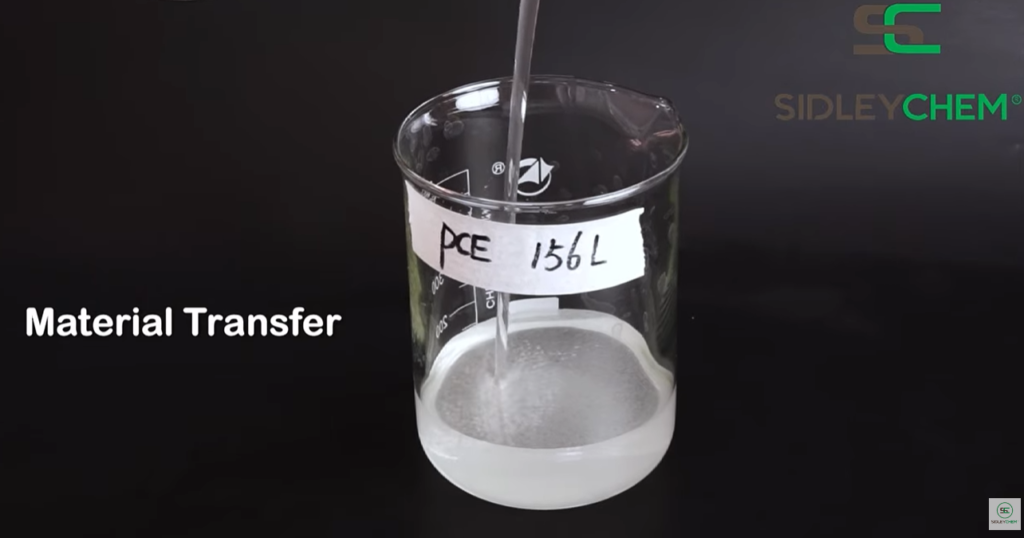

4.Use water-based release agents instead of waste oil or oil-based agents to reduce bubble adsorption and enhance surface smoothness.

IV. SidleyChem Dedicated Product Solutions

To address concrete appearance quality issues, we offer the following specialized products:

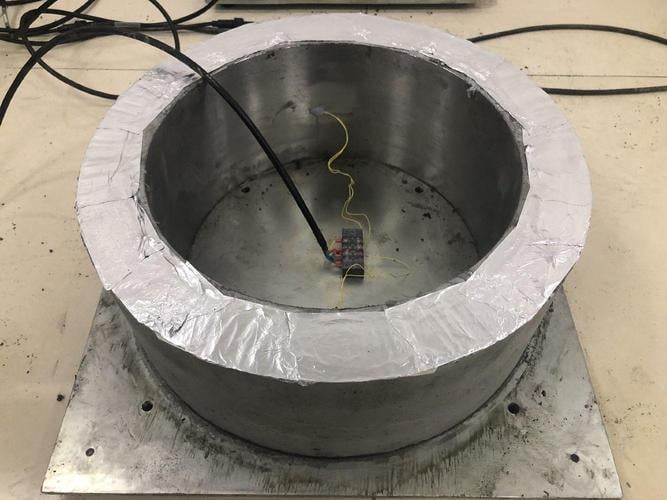

Surface Improving Admixtures: Finish DF430

Defoamer: DF330L

Air-Entraining Agent: AE180P, LWC50

Release Agent:RL99

Stabilizer: VMA, Stabilizer 5R