Microbead spherical powder

In the modern building materials sector, innovation often stems from rethinking the nature of materials themselves. While the industry has long focused on chemical adjustments, a novel material achieving breakthroughs at the physical morphology level – ultramicro-spherical pozzolanic powder (Microbead) – is demonstrating unique value.

Core Advantage: Starting from a Unique Physical Morphology

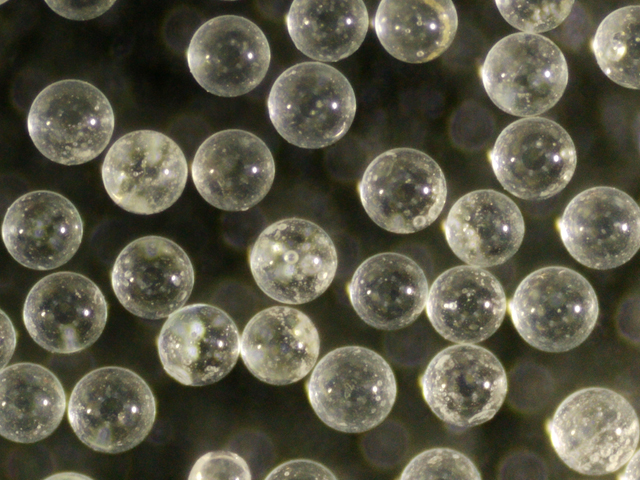

The defining characteristic of Microbead lies in its perfectly spherical particle morphology and continuous particle size distribution. This ultrafine spherical powder, produced through specialized processes, fundamentally alters the irregular shapes of traditional powders, resulting in a series of chain-optimization effects in application.

Three Key Action Mechanisms: From Physical Optimization to Performance Enhancement

1. Ball-Bearing Lubrication & Physical Water-Reducing Effect

1. Ball-Bearing Lubrication & Physical Water-Reducing Effect

Due to the minimal surface energy of spherical particles, Microbead significantly reduces inter-particle friction within the paste. This “ball-bearing effect” directly translates into excellent physical water reduction. Under conditions maintaining the same fluidity, a 10-15% water reduction rate can be achieved, while simultaneously improving pumpability and workability.

2. Micro-Aggregate Filling & Gradation Optimization Effect

Spherical particles with a continuous size distribution can perfectly fill the voids within the cementitious system, achieving the densest possible packing. This micro-level gradation restructuring results in a denser hardened microstructure with significantly reduced porosity, thereby enhancing compressive strength, impermeability, and durability.

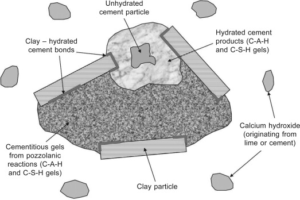

3. Slow-Release Pozzolanic Activity Effect

Chemically, Microbead primarily consists of aluminosilicates (Typical: SiO₂ 56.5%, Al₂O₃ 26.5%). Its dense vitreous surface is relatively inert during early hydration, primarily serving a physical filling role. This benefits early-age heat reduction and shrinkage control. Over time, a gradual pozzolanic reaction under alkaline conditions contributes to long-term strength gain.

This “physical filling early, chemical enhancing later” characteristic allows it to balance workability and durability when combined with materials like silica fume, offering new design avenues for high-performance concrete.

As a supplier focused on innovative solutions, SidleyChem‘s Microbead series offers size-adapted products for various scenarios. After understanding the principles, let’s explore its practical applications.