Microbead applications

Based on unique physico-chemical properties, Microbead materials have moved from lab research to broad engineering applications. Their value extends beyond cementitious materials into multiple industrial fields, showing promise as a multi-functional filler.

Key Applications in Cementitious Building Materials

High-Performance Concrete Fields

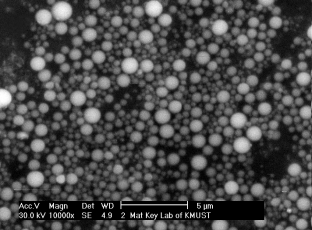

In UHPC and high-strength concrete, Microbead serves as a functional supplementary material. Its physical water reduction helps lower the water-cement ratio, the micro-filling effect increases density, and its slow-release activity benefits workability retention and long-term strength. Practical projects show that with proper dosage, concrete strength can increase by 10-25% at various ages, while chloride ion permeability significantly decreases.

Self-Compacting and High-Flowability Systems

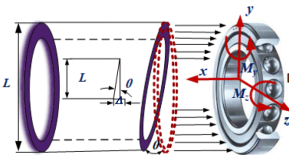

For systems requiring high fluidity like Self-Compacting Concrete (SCC) and self-leveling mortars, the ball-bearing effect of Microbead significantly improves rheological properties. Its spherical particles help stabilize the paste, prevent aggregate segregation, and make achieving self-leveling and self-compacting states easier, ideal for complex structural casting and thin-layer application.

Its spherical particles help stabilize the paste, prevent aggregate segregation, and make achieving self-leveling and self-compacting states easier, ideal for complex structural casting and thin-layer application.

Special Engineering Applications

In mass concrete, the low early-heat characteristic of Microbead aids in temperature control and crack prevention. In corrosion protection projects, its density-enhancing effect improves chemical erosion resistance. In repair mortars, it balances fluidity and compressive strength needs.

Key Applications in Cementitious Building Materials

Cross-Industry Application Expansion

The value of Microbead extends beyond building materials. Leveraging its spherical, high-strength, heat-resistant, and insulating properties, it plays a role in several industries:

-

Polymer Composites: As a functional filler in plastics/rubber to improve processing flow, dimensional stability, surface gloss, and mechanical strength.

-

Refractory Materials: For producing lightweight, high-strength refractory products, balancing insulation and structural strength.

-

Functional Products: Used in sound-absorbing materials, friction materials, artificial stone, etc., leveraging specific physical advantages.

-

Other Industries: As catalyst supports, precision casting sand, etc.

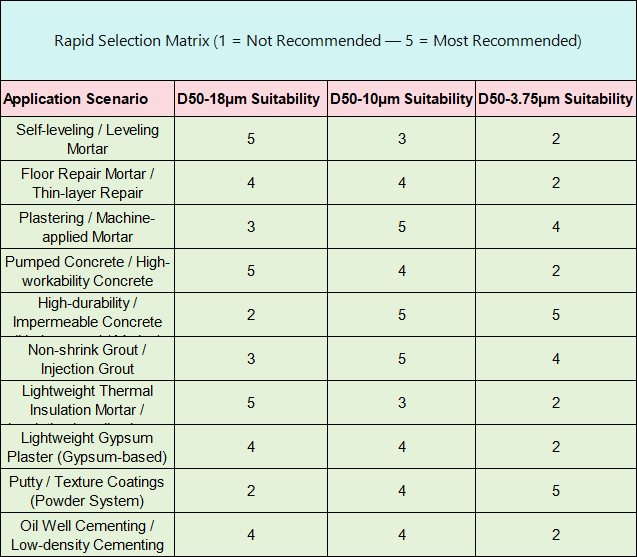

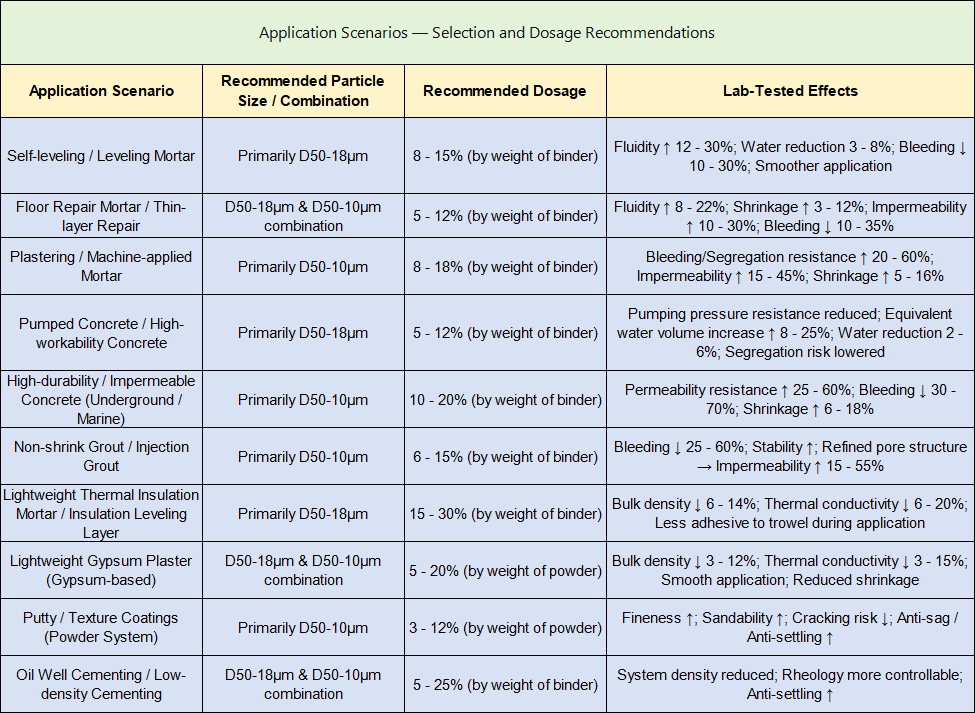

For innovative applications in building materials, SidleyChem’s technical team has accumulated systematic application data for Microbead products (e.g., D50=10μm, 18μm) in systems like UHPC and self-leveling mortars, providing targeted technical selection advice.

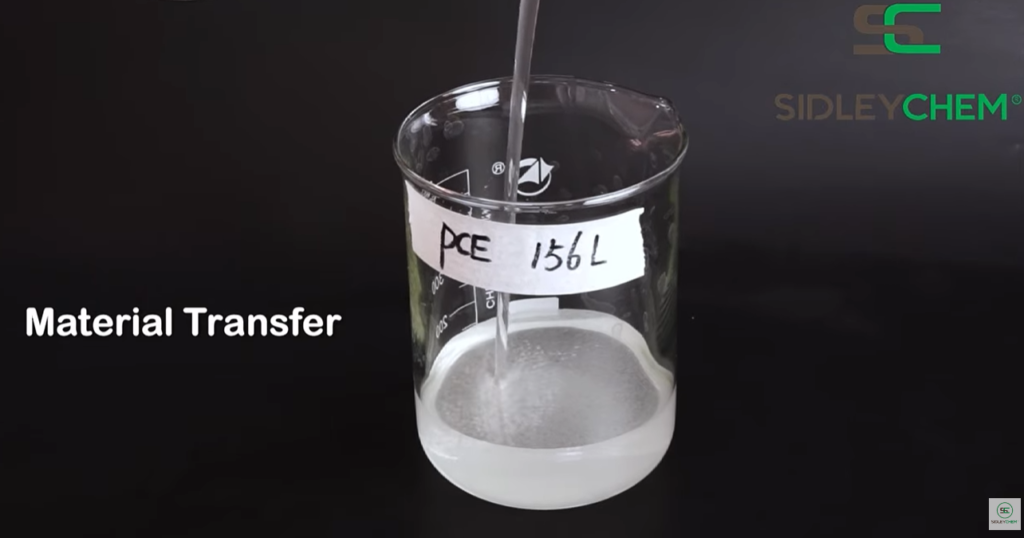

Application Guidance & Outlook

In practice, the typical dosage of Microbead is 3-10% of the total cementitious material, determined through testing based on system requirements. Synergistic effects are achieved when used with polycarboxylate superplasticizers, combining physical and chemical water reduction.

As performance requirements for materials increase, spherical powders like Microbead are becoming an effective pathway towards high performance and functionalization. From improving workability to enhancing durability, and from single material applications to cross-functional uses, the technological approach represented by Microbead provides a noteworthy direction for material innovation.