Architectural coating system

Architectural coatings serve three primary functions: decoration, protection, and, in some cases, special functionalities.

1. Decorative Function

The primary purpose is to enhance a building’s aesthetics by concealing surface imperfections, creating a pleasing appearance that integrates with its surroundings. Decoration encompasses both visual qualities (color, pattern, gloss) and textural qualities (design of three-dimensional textures).

-

Interior vs. Exterior: While the goal is similar, standards differ. Interiors often favor flat finishes, low-gloss textures, or subtle color patterns. Exteriors typically require higher durability and may utilize glossier finishes or pronounced textured patterns for visual impact.

2. Protective Function

Coatings shield substrates from degradation caused by oxygen, moisture, UV radiation, and airborne pollutants, thereby extending the structure’s service life. Protection requirements vary by substrate:

-

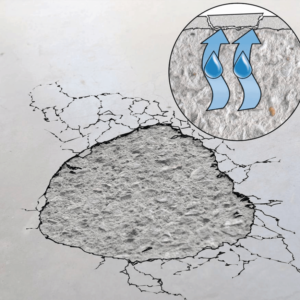

Concrete/Masonry: Coatings must manage moisture (waterproofing, breathability) and resist carbonation, sulfur dioxide, and chemicals.

-

Metal: Anti-corrosion is paramount.

-

General: Exterior coatings face harsher conditions (rain, temperature cycles, UV exposure) and therefore demand higher performance specifications than interior coatings.

3. Special Functions

Specific applications require additional properties:-

Interior: Sound absorption, anti-condensation, anti-mold, or low-VOC/air-purifying features.

-

General: Fire resistance, waterproofing, radiation shielding, insecticidal, or thermal insulation properties.

-

Coating System Structures

A coating system is a multi-layer assembly where each layer has a distinct role.

1. Interior Wall Coating System (2-Layer)

After wall leveling with filler, the system typically consists of:

-

Primer

-

Topcoat (x2)

2. Exterior Wall Coating System (3-Layer)

After wall leveling with filler, the system typically consists of:

-

Primer

-

Mid-Coat

-

Topcoat

Role of Each Coating Layer

Interior System:

-

Primer: Seals alkaline substrates, improves topcoat adhesion, and enhances film integrity and smoothness. Skipping the primer can lead to topcoat failure, manifesting as chalking, yellowing, alkali burn, poor adhesion, and reduced service life.

-

Topcoat: Provides the final decorative effect and protection. Interior topcoats require specific colors/patterns, moisture control (water resistance, breathability), stain resistance, scrub resistance, low toxicity, and sometimes special functions like fire retardancy or sound absorption.

Exterior System:

-

Primer: Functions similarly to interior primer: seals alkalinity and enhances adhesion to prevent chalking, yellowing, and alkali burn.

-

Mid-Coat: Provides key opacity, improves build/film thickness (reducing topcoat consumption), and creates textured patterns. It is the main layer in textured finish systems.

-

Topcoat: The final layer must offer both long-term aesthetics and robust environmental protection. Exterior topcoats require high durability (weather resistance, dirt pick-up resistance), water resistance, and UV stability. The design goal is for decorative and protective lifespans to be well-matched, ensuring no material performance is wasted.