Plastic Expansive Agent for Duct Grouting

The plastic expansive agent for duct grouting is a key functional material that ensures the compactness of grouting in prestressed engineering. This article clearly explains its definition, core composition, mechanism, and primary application scenarios.

1. Core Definition

A plastic expansive agent for duct grouting is a specialty functional admixture designed specifically for grouting ducts in prestressed structures. Its core action occurs during the plastic stage of the grout (3~6 hours before initial setting). It generates micro-expansion through controlled gas formation to precisely compensate for the grout‘s bleeding and plastic shrinkage during this stage (which accounts for over 85% of total shrinkage), thereby effectively preventing the formation of voids, stratification, or water channels inside the duct. While ensuring the grout’s fluidity and later-stage bond performance, it is the key material for solving the issue of duct filling compactness.

2. Core Chemical Composition

Its design focuses on low dosage and safe gas generation to avoid negative impacts on the grout’s strength and durability.

-

Main Expansion Components: Typically include azo-based organic compounds, nitrogen-generating composite salts (e.g., specific sulfamate derivatives), or bauxite-based mineral powders that have undergone high-temperature sintering and surface treatment.

-

Auxiliary Functional Components: Include composite stabilizers (to control gas generation rate), trace defoamers (to eliminate harmful large air bubbles), and workability-retaining agents (to match the required construction operation time).

-

Key Control Indicators: Very low chloride ion content (≤0.001%, no corrosion risk), and free of aluminum powder and high-alkali components. The product usually appears as a yellow or golden-yellow crystalline powder.

3. Expansion Mechanism

It employs a “gentle gas-forming expansion” mode, fully compatible with the characteristics of the grout’s plastic stage:

-

Trigger Conditions: Activation relies on the alkaline environment generated by cement hydration (pH≥12) or initiates decomposition under the heat of hydration (40~60℃).

-

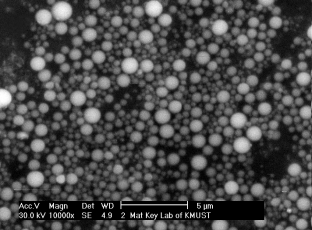

Gas Generation Process: Slowly releases inert gases such as nitrogen (N₂) or a nitrogen-acetylene mixture, forming uniform and dense micro-bubbles (pore size <50μm) within the grout. The pressure generated by these bubbles drives the volumetric expansion of the grout, compensating for bleeding and plastic shrinkage.

-

Expansion Characteristics: The main expansion is completed within 3 hours (vertical expansion rate of 0.1%~0.5%). The gas generation rate is well-matched with the grout’s initial setting time. There is no later-stage shrinkage rebound after expansion.

4. Key Application Scenarios

-

Core Application Scenario: Grouting for ducts in post-tensioned prestressed structures, widely used in highway/railway bridges (especially curved, vertical, or extra-long ducts), and prestressing systems with extremely high compactness requirements such as in nuclear power plants and high-rise buildings.

-

Extended Application Scenarios: Grouting for prestressed anchor fixation, grouting for structural joints in prefabricated buildings, repair grouting for concrete defects (to prevent plastic stage settlement), etc.

5. SIDLEYCHEM Product: Application Parameters for Plastic Expanding Agent PEA50P

-

The Plastic Expanding Agent PEA50P offered by SIDLEYCHEM is a high-performance product. Its application key points are as follows:

-

Recommended Dosage Range (by mass of total cementitious material):

-

Standard Prestressed Duct Grouting: 0.05%~0.1%

-

Complex Curved or Extra-Long Duct Grouting: 0.1%~0.2%

-

High-Grade Grout (C80 and above): 0.03%~0.08%

(Note: Effective at very low dosage. The optimal dosage should be determined through trials based on the specific mix design.)

-

-

Key Performance and Technical Indicators (Compliant with standards like GB/T50448-2008, JTG/TF50-2011):

-

Gas Generation Characteristics: Uniform gas generation within 3 hours, without concentrated violent bubbling.

-

Grout Performance: Good initial fluidity (10~17s flow), 0% bleeding at 30 minutes.

-

Impact on Strength: Minimal impact on 28-day compressive strength, typically with a loss of ≤5% (compared to reference grout).

-

Expansion Rate: Stable 3-hour vertical expansion rate within the range of 0.1%~0.5%, with no reverse shrinkage within 24 hours.

-

-