Check if Your Detergent & Cleaning Products Are Qualified

Ensuring the quality of your household cleaning and laundry products is crucial for both effectiveness and safety. Instead of relying on brand claims alone, you can perform some simple checks. This guide outlines four direct methods to evaluate the basic quality of products like laundry liquids, dish soaps, and other cleaners.

1. Check the Active Matter Content

The cleaning power of a product largely depends on its active matter (or active ingredient) content. This information is often found on the technical data sheet or product label.

Example Standards: For instance, standard laundry liquids should have a total active matter content of ≥15%, while delicate fabric washes should have ≥12%, and pretreatments for collars/cuffs ≥6%.

Why It Matters: A content lower than these benchmarks significantly reduces cleaning efficacy, meaning you’ll need to use more product for the same result.

2. Inspect the Physical Appearance

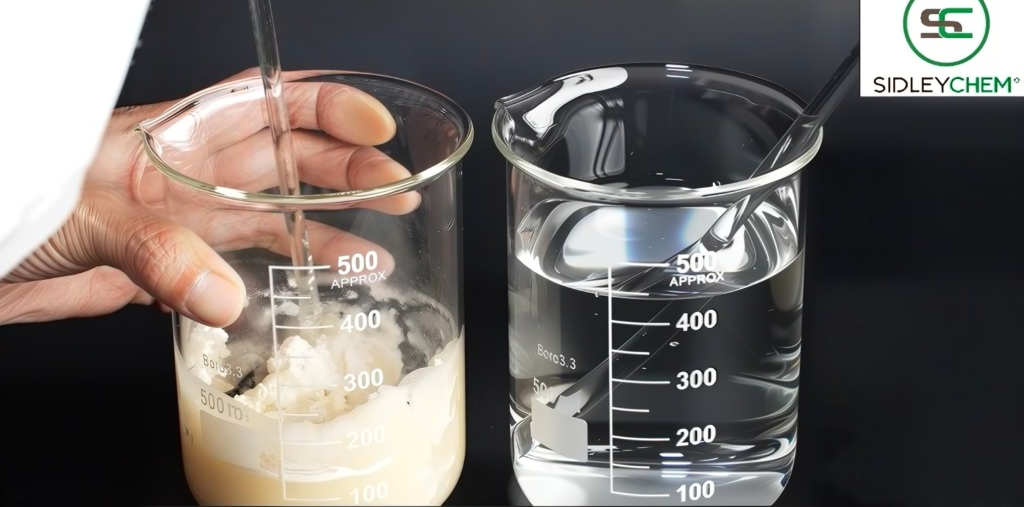

The product’s packaging and liquid appearance offer immediate clues.

Packaging: Qualitatively produced items have clean, well-molded bottles with sharp, clear, and smudge-free printing. Legitimate manufacturers will clearly state usage instructions, execution standards, net content, manufacturer address, and shelf life.

Liquid Form: The liquid itself should be uniform in color and consistency. Separation, unusual sedimentation, or suspended particles can indicate product degradation, contamination, or formulation issues.

3. Assess the Viscosity (Thickness)

While different products have different intended viscosities, drastic deviations from the norm for a similar product type can signal problems.

Too Thick: May indicate excessive use of thickeners to mask a low active content.

Too Thin/Watery: Could mean the active ingredients are insufficient, or the product has been improperly diluted.

4. Smell the Product

A qualified cleaner should have a characteristic, stable fragrance appropriate for its type.

Warning Sign: Any off-putting, sour, or rancid odor is a strong indicator that key components have begun to break down or spoil.

Conclusion

By applying these four straightforward checks—reviewing active content, inspecting appearance, feeling viscosity, and noting odor—you can make a more informed initial judgment about the quality of your cleaning products. For manufacturers and formulators, adhering to strict quality control and using high-grade raw materials is the foundation of producing trustworthy and effective cleaners.

By applying these four straightforward checks—reviewing active content, inspecting appearance, feeling viscosity, and noting odor—you can make a more informed initial judgment about the quality of your cleaning products. For manufacturers and formulators, adhering to strict quality control and using high-grade raw materials is the foundation of producing trustworthy and effective cleaners.