concrete mineral admixtures

I. Product Definition and Primary Applications

High-performance inorganic mineral admixtures are slurry-based additives composed of one or more raw materials containing silicon, aluminum, calcium, and other oxides. These materials undergo wet grinding to form liquid mixtures with specific water content and defined fineness.

Primary applications of high-performance inorganic mineral admixtures:

Enhancing concrete performance: Significantly improves concrete strength, durability, and impermeability while enhancing fluidity and workability.

High-performance ceramics production: Serves as a crucial raw material for manufacturing high-performance ceramics, improving their strength, hardness, and wear resistance.

Metallurgical industry applications: Used in ladle casting, foundry processes, and flux manufacturing.

II. Core Application Advantages in Concrete

Advantages of using high-performance inorganic mineral admixtures in concrete:

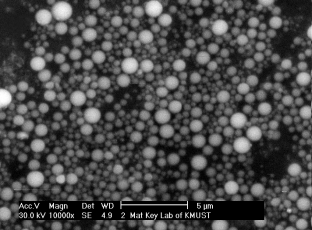

High reactivity: The main component, silicon dioxide, exhibits high reactivity and can react with cement hydration products to generate substantial calcium silicate gel. This gel fills pores in concrete, enhancing density and strength.

Improved fluidity: Features a narrow particle size distribution. Incorporating both fine and some coarse particles helps optimize the dense packing of cementitious materials, resulting in better fluidity. This addresses issues such as concrete stickiness and slow flow, particularly in external mixing and high-grade concrete applications, where overall fluidity shows significant improvement.

Enhanced durability: Improves concrete’s resistance to acid and alkali corrosion, freeze-thaw cycles, and carbonation.

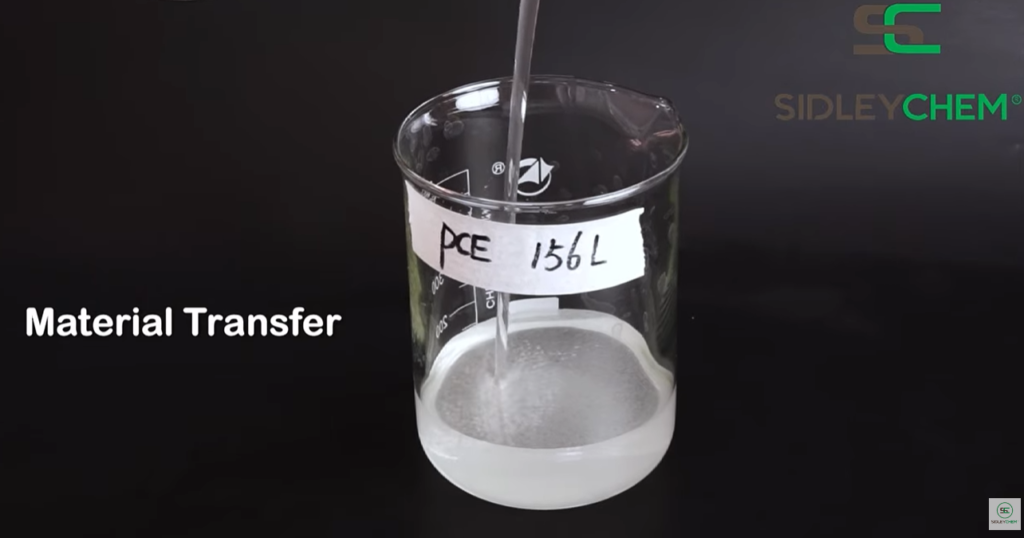

Environmentally friendly and convenient: The product is supplied as a slurry, dust-free, directly pumpable through pipelines, easier to add and measure, convenient for transportation and storage. It offers short-term stability without settling or stratification, and maintains reactivity even after prolonged storage.

III. Company Solutions and Products

How to maintain or even improve concrete quality while enabling easier quality control, using raw materials that are environmentally friendly, low-carbon, and convenient? Against this backdrop, SidleyChem has persistently strived for continuous improvement and developed SidleyChem Fume45, a high-performance inorganic mineral admixture for concrete with silicon dioxide as the main component. Repeated testing has demonstrated its effectiveness in overcoming the aforementioned drawbacks:

1.In concrete, the performance of 1 kg of SidleyChem Fume45 (40% solid content) exceeds that of 1 kg of densified silica fume added dry.

2.In concrete, incorporating 1 kg of SidleyChem Fume45 (solid equivalent) can replace 3-5 kg of cement while maintaining constant volume weight (with sand filling any weight deficiency).

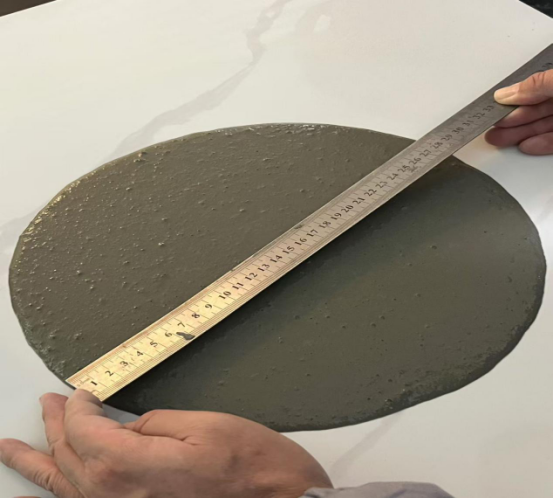

3.Adding 10-30 kg of SidleyChem Fume45 to concrete significantly improves its workability.

4.Externally adding 10-30 kg of SidleyChem Fume45 to concrete can increase the 28-day strength by 4-7 MPa.