low-clinker cement challenges

Background

Currently, the concrete and cement industries are among the primary sources of CO₂, accounting for 7-8% of global carbon dioxide emissions. In the coming years, global concrete demand will surge significantly, and emissions from this sector will continue to rise. To achieve carbon neutrality by 2050, one of the fastest and most effective methods is to reduce the clinker content in cement—that is, replacing low-clinker cement challenges with supplementary cementitious materials.

All these new “low-clinker” cements (limestone cement, pozzolanic cement, calcined clay cement) fully meet current cement standards for mortar (strength, setting time, water demand). However, they present new challenges in concrete applications because using low-clinker cement significantly impacts concrete performance.

Impact of Low-Clinker Cement on Concrete Properties

2.1. Reduced Early Strength Affecting Formwork Removal: Due to lower clinker content, low-clinker cement produces insufficient early-stage hydration products, resulting in 1-day and 3-day strengths 30%-50% lower than ordinary cement. This impedes normal formwork removal for components.

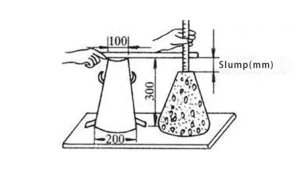

2.2. Reduced workability affecting construction performance: The increased water demand of low-clinker cementitious systems leads to rapid slump loss, impairing workability. To maintain normal construction performance, the dosage of superplasticizer must be increased (by approximately 10%-20%).

2.3. Weakened carbonation resistance: The low Ca(OH)₂ content in low-clinker systems results in a 15%-30% increase in carbonation depth compared to ordinary cement.

Sidley Chemical admixtures provide concrete producers with the following solutions

It is widely recognized that advancements in concrete technology are highly dependent on the development of admixture technology, primarily manifested in performance enhancement and construction optimization.

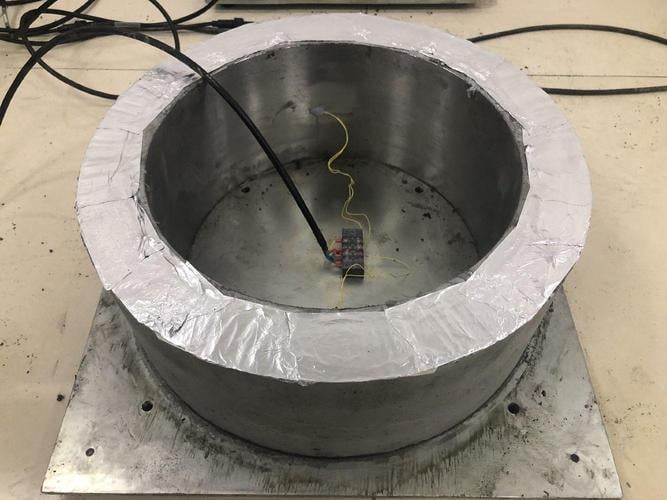

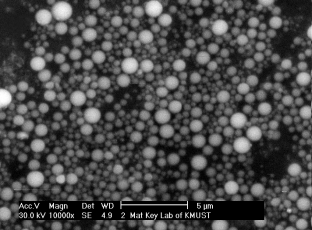

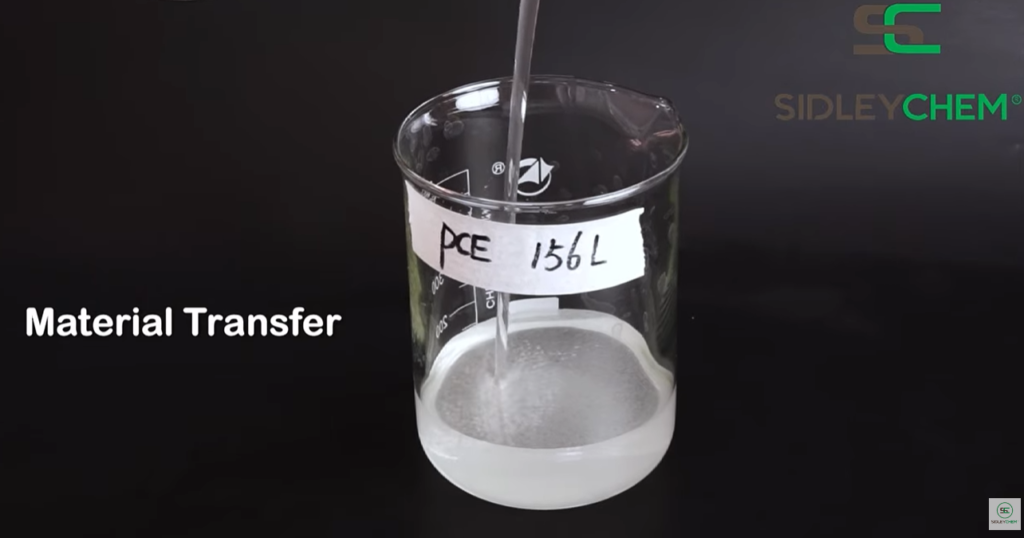

3.1. Applications such as Sidleychem Polycarboxylic superplasticizer Technology, Sidley Viscosity Modifying Agent Technology, and Sidleychem Air-Entraining Agent Technology significantly improve concrete workability. It’s like injecting “vitality” into concrete, enabling smoother flow and forming during construction. Whether for complex structures or large-area pours, it handles them effortlessly. Additionally, concrete slump loss is minimized—acting like a “stabilizer” that maintains excellent workability even during long-distance transport and extended construction periods, ensuring smooth project execution.

3.2. Applications like Sidleychem defoamers, and Sidleychem Shrinkage Reducing Admixture technology reduce the distance between cement particles, promote cross-linking, and enhance concrete strength. Simultaneously, they improve crack resistance, minimize surface cracking, and elevate both the appearance and quality of the structure.

Sidleychem Product Recommendations:

Polycarboxylic superplasticizer :PCE1056L, PCE1046L

Air-entraining agents:AE180P, Finish200

Viscosity Modifying Agent:Stabilizer 5R