Precast Concrete

Ⅰ. Definition

Precast concrete refers to concrete elements manufactured in advance in factories or on-site, which are then transported and installed into their final positions using lifting equipment. It is widely applied in building, municipal, and industrial sectors.

Ⅱ. Advantages and Features

2.1 Enhanced Efficiency: Factory prefabrication shortens project timelines, while on-site assembly significantly accelerates construction progress.

2.2 Quality Control: Standardized production ensures precise concrete mix proportions and curing, delivering uniform component strength.

2.3 Environmental Sustainability: Reduces on-site wet operations and material waste while minimizing dust and noise pollution.

2.4 Safety and Durability: Prestressing technology enhances crack resistance, with seismic performance comparable to cast-in-place structures.

Ⅲ. Product Categories

3.1 Architectural Finishing: Includes exposed concrete wall panels, GRC cladding panels, UHPC components, etc., with surfaces achievable in colored, exposed aggregate, or stone finishes.

3.2 Structural Load-Bearing: Components such as box girders, T-beams, precast shear walls, composite slabs, beams/columns, and staircases, serving as core load-bearing elements in prefabricated buildings.

3.3 Municipal & Landscape: Covers subway tunnel segments, utility tunnels, curbstones, garden ornaments, paving bricks, and more.

3.4 Port & Marine: Includes twisted king blocks, caissons, and other components for coastal protection and wharf construction.

Ⅳ. SidleyChem: Your Partner for High-Performance Concrete Solutions

SidleyChem boasts a technical team with over 20 years of production and formulation expertise. Our production processes, rooted in German technology, ensure the exceptional and consistent performance of our concrete admixture products. We are not only a supplier of premium products but also your trusted partner for concrete technology solutions, dedicated to helping clients overcome various technical challenges from production to application. Listening to your needs, we design high-performance, customized admixture solutions for you.

SidleyChem boasts a technical team with over 20 years of production and formulation expertise. Our production processes, rooted in German technology, ensure the exceptional and consistent performance of our concrete admixture products. We are not only a supplier of premium products but also your trusted partner for concrete technology solutions, dedicated to helping clients overcome various technical challenges from production to application. Listening to your needs, we design high-performance, customized admixture solutions for you.

Ⅴ. SidleyChem Functional Admixtures for Precast Concrete

To meet the demanding requirements of precast components for efficient production and exceptional quality, we offer a range of market-proven specialty chemicals:

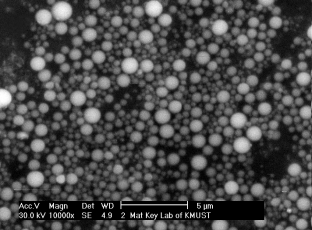

Early-strengthpolycarboxylate superplasticizers(e.g., PCE20SP, PCE1085L, PCE1086L, PCE1096L): Significantly enhance early strength while maintaining excellent workability, boosting production efficiency.

Surface Finish Enhancers (e.g., Finish DF430): Effectively eliminate surface bubbles and imperfections, improving density and smoothness to directly achieve high-quality decorative finishes.

Curing Agents (e.g., HC, HCP): Form an effective water-retaining film to prevent plastic shrinkage cracks, ensure complete cement hydration, and guarantee strength development.

Surface Retarder (e.g., TARD-S): Used to create special finishes like exposed aggregate, selectively delays surface cement hydration to achieve rich textures and patterns.

Shrinkage Reducer (SRA): Reduces chemical shrinkage at the source, effectively preventing early plastic cracking and drying shrinkage cracks.

Early Strength Agent (e.g., SETAC 205): Promotes strength development even in low-temperature environments without causing reinforcement corrosion.

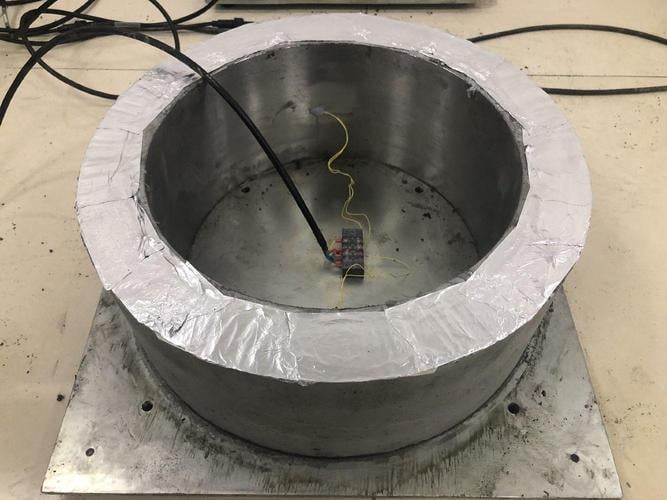

Release Agent (e.g., Finish RL99): Ensures smooth demolding without affecting concrete surface color or quality, while protecting molds and extending their service life.