PCE synthesis procedure

Polycarboxylic Superplasticizer (PCE) is widely used as a high-performance water reducer in concrete admixtures. The following article presents a practical laboratory-scale synthesis procedure, reflecting real experimental steps and commonly used raw materials such as Water, HPEG2400, Chain Transfer Agents, Oxidant, AA, OA (Oxidant Agent), and Reducing Agent. This technical overview is suitable for construction chemical manufacturers and suppliers seeking a clear and reliable synthesis workflow.

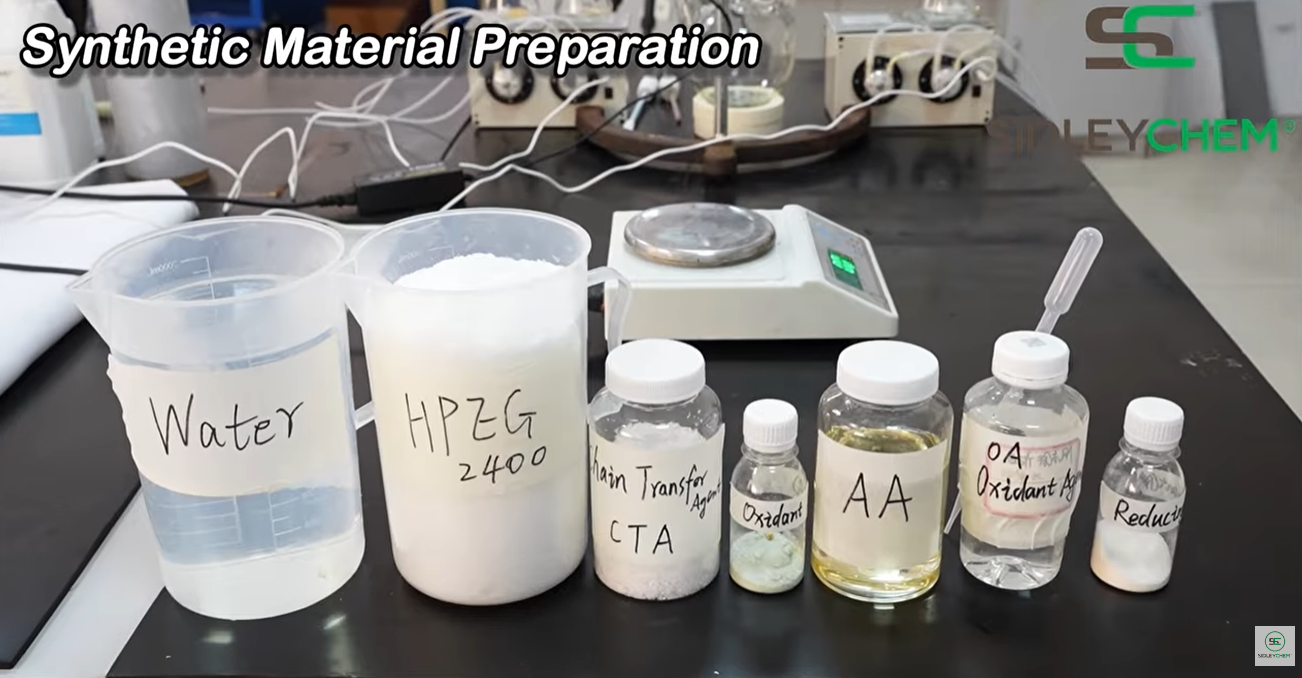

1. Raw Materials Used in the Synthesis

The laboratory synthesis of PCE involves the following materials:

-

Water

-

HPEG2400 (polyether macromonomer)

-

Chain Transfer Agents

-

Oxidant

-

AA (Acrylic Acid)

-

OA (Oxidant Agent)

-

Reducing Agent

These materials are weighed according to the required formulation before the reaction begins.

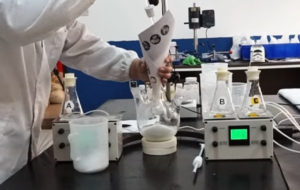

2. Preparation of Solutions A, B, and C

-

Before polymerization, three solutions are prepared separately:

-

Solution A: AA + Water

-

Solution B: OA + Water

-

Solution C: Reducing Agent + Water

Each solution is stirred until fully dissolved, ensuring accurate concentration for controlled polymerization.

-

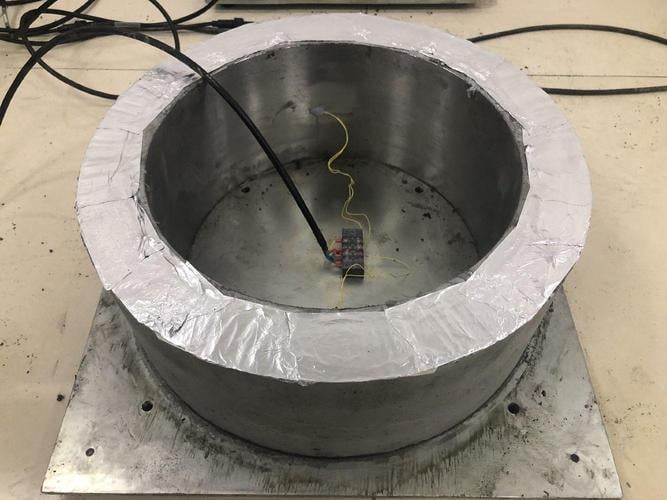

3. Equipment Setup

The reaction kettle and all auxiliary equipment are prepared in advance. Stirring, temperature control, dosing pumps, and protective systems are checked to ensure stable operation throughout the process.

4. Feeding Sequence and Polymerization Procedure

After solutions A, B, and C are fully prepared, the following feeding sequence is used:

After solutions A, B, and C are fully prepared, the following feeding sequence is used:

-

Add HPEG2400, Water, Chain Transfer Agents, and Oxidant into the reactor.

-

Set the dropwise-addition time for A, B, and C according to the required reaction profile.

-

Add the small-volume materials (white measuring cups).

-

Wait 10 minutes, then begin dropwise addition of Solution A.

-

After 5 minutes, start simultaneous dropwise addition of Solutions B and C.

-

The whole reaction lasts 50–70 minutes.

-

During feeding, monitor temperature and color changes, and record key observations.

When all raw materials have been added, the polymerization process is complete.

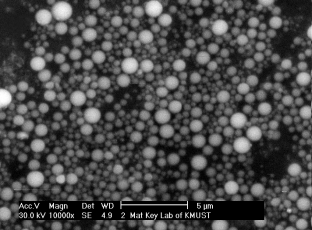

5. Completion of PCE Mother Liquor

After the reaction finishes, the mixture is stirred until uniform. At this stage, the PCE mother liquor is successfully synthesized and can be filtered or adjusted depending on downstream application requirements.

After the reaction finishes, the mixture is stirred until uniform. At this stage, the PCE mother liquor is successfully synthesized and can be filtered or adjusted depending on downstream application requirements.